Delivering the class-leading engineering performance and quality standards we’ve come to expect from Timney, this new drop-in trigger for AKM-pattern rifles is easy to install and is a real game-changer for AK fans

by Rob Reaser

Let’s be up-front-honest. AKs are about as indelicate as coal shovels and sledgehammers.

And that’s why we like them. Better stated, that’s why I and many others like them. You can use them and abuse them, drop them, kick them, ride ’em hard and put ’em up wet, treat them like your worst enemy and they’ll say, “Thank you! May I have another, please?”

Of course, the 7.62×39 payload is also welcome. As a defensive load, it has the kind of downrange wallop that no serious-minded shooter would hike their nose at.

The trade-off for all that hairy-knuckled character, though, is, historically speaking, second-string accuracy when compared to, say, an AR sporting a quality barrel, and operational controls that verge on the ham-fisted.

Take the AKM trigger, for example. There is nothing refined about it — at least not the triggers found in the classical AKM builds. My AK was hand-made from a greasy, dirty bag of demilitarized Romanian Model 63 parts. Like many such AKM builds that must meet 922r compliance, the trigger is one of those items on an imported semi-auto rifle that is typically sourced from a domestic manufacturer. For my build, we used a Tapco single-hook trigger group.

As AK triggers go, it proved reliable but far from optimal. That’s no knock on Tapco — it’s just the nature of MILSPEC-style AKM triggers. The pull length was a mile long and the trigger reset mere inches shy of that. Overtravel was also excessive. The sear had only a couple minor catches yet was, overall, relatively smooth. Trigger pull weight, though, proved a bit on the light side at an average 2 lb., 11.2 oz. That is WAY too light for a defensive firearm in my opinion.

In short, the gun performed admirably despite the so-so trigger, and I have no problem busting clays at 100 meters with the factory iron sights. But when our friends at Timney Triggers asked if we would want to test drive their newest and first-ever AK Drop-In cassette trigger, my ready answer was, “Does squirrel make the best gravy?”

Been There, Done That

Some might scratch their heads at the notion of Timney developing a precision trigger for the brutish AKM rifle. In truth, “precision” and “AKM” are two words that rarely go together (this might be the first instance of such!). The stamped steel and rivet construction of traditional AKMs makes each a “custom build” in the eyes of experienced machinists. And yet Timney went for it. Why? Well, why not?

Timney Triggers started in 1946 when Allen Timney began developing precision, easy-to-install triggers to upgrade the military issued Springfield, Mausers, and Enfields that returning service veterans were “sporterizing” for their hunting pursuits. Like the AKM-pattern rifles, these were also rough-and-tumble firearms born and tested on the battlefield and mass produced to satisfy a war effort.

You might ask, then, what took Timney so long to come out with a trigger for the AKM — especially since the company has been producing precision drop-in triggers for the AR-15 platform for many years? The economies of demand, naturally, played a role. More importantly, though, is that Timney refuses to release any product until it meets all the company’s requisite benchmarks for performance and quality as well as elegant simplicity from the consumer’s perspective.

“We had been working on an AKM trigger solution, off and on, for many years,” explained Timney VP of Marketing and Communications Chris Ellis. “As you know, nothing goes out our doors until it is right. Given all the AKM variants out there, with patterns unique to countries around the world, it took a lot of engineering, testing, more engineering and testing, and buying a whole lot of AKMs of the various flavors to use as test mules for fit and operation. I can’t even tell you how many rounds of 7.62×39 we burned in our field tests. But that’s how we roll.

“There are just so many quirks and variables encountered when trying to develop a single product to cover so many different rifle patterns and manufacturers. But we’ve put in the sweat equity and think the new AK Drop-In trigger system is as close to the mark as you can get. Our customers asked for it, so we delivered.”

Timney AK Drop-In Trigger Details

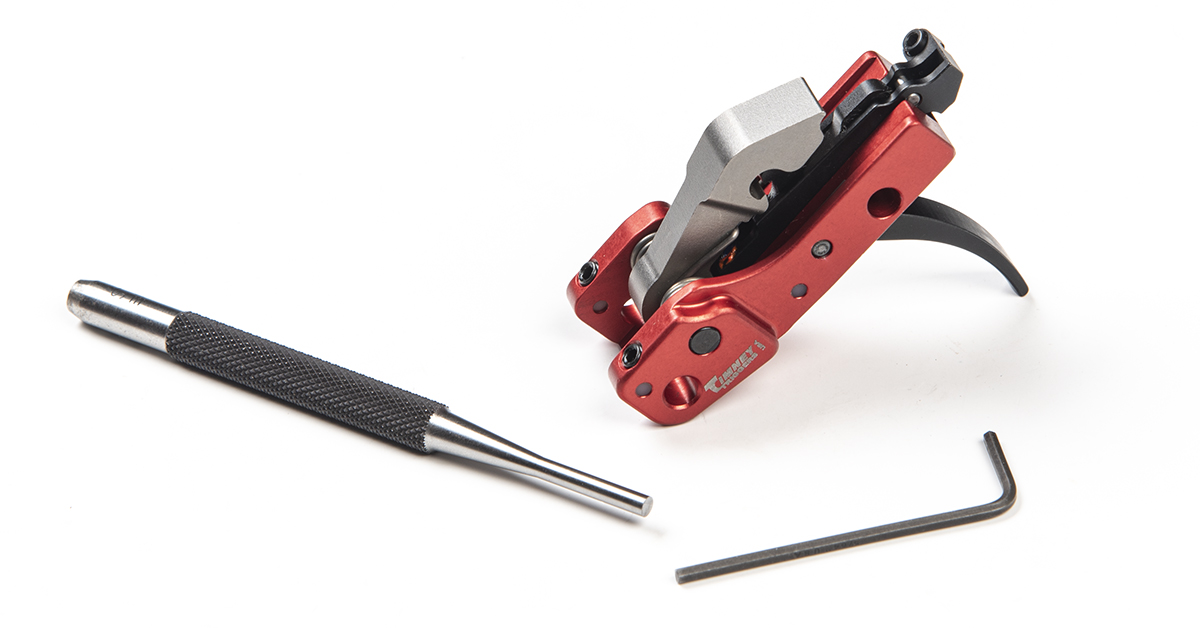

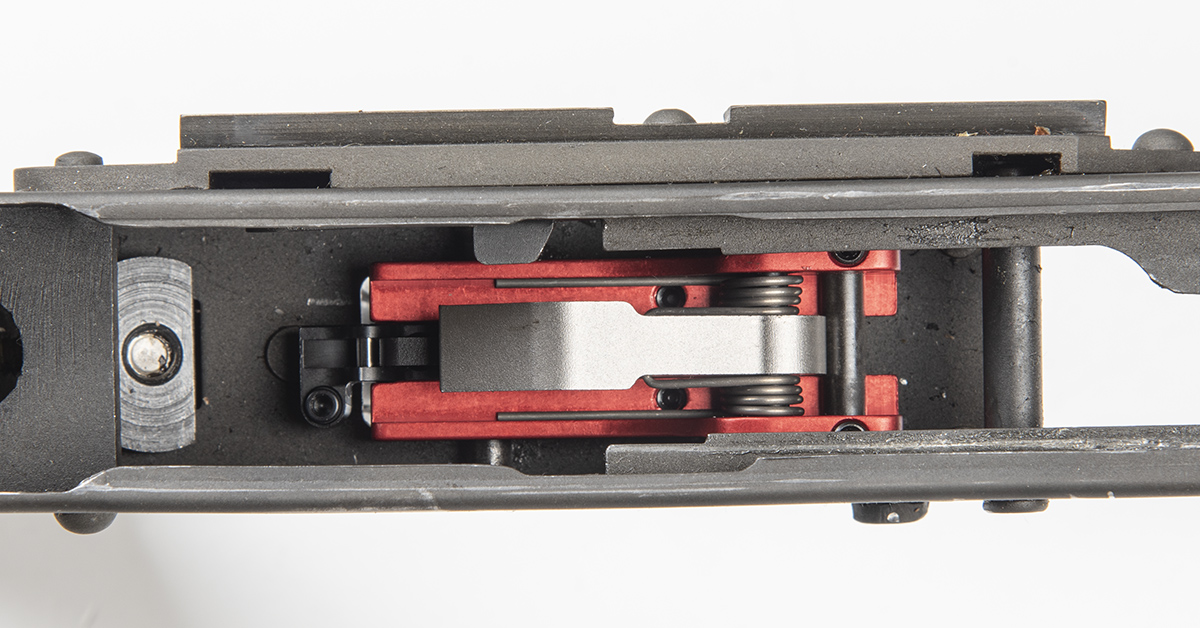

If you are familiar with Timney’s wide range of drop-in trigger systems, you can tell at a glance that the new AK Drop-In sports all the right DNA. This is a unitized trigger group with the trigger and hammer assemblies contained in a machined and anodized 6061 T6 alloy housing, or cassette. The hammer is made of S7 tool steel with an MP3 coating. A2 tool steel with a carbon nitride finish make up the disconnect while the trigger shoe is comprised of tool steel and boasts a black oxide finish.

It is similar in concept to the company’s AR-15 drop-in triggers in that it secures the cassette to the receiver with the factory trigger and hammer pins. Set screws provide the final adjustments for a solid and precisely aligned fitment.

Speaking of fitment, the big question for AKM owners is, “What rifles and countries of origin does the trigger fit?”

Well, pretty much everything you’ll likely acquire in the US. The covered countries of origin include:

- Russian

- Romanian

- Hungarian

- East German

- Bulgarian

- Chinese

- Korean

- Polish

- Serbian

- US

- Yugoslavian

That is quite a broad swath in the AKM world for a single component.

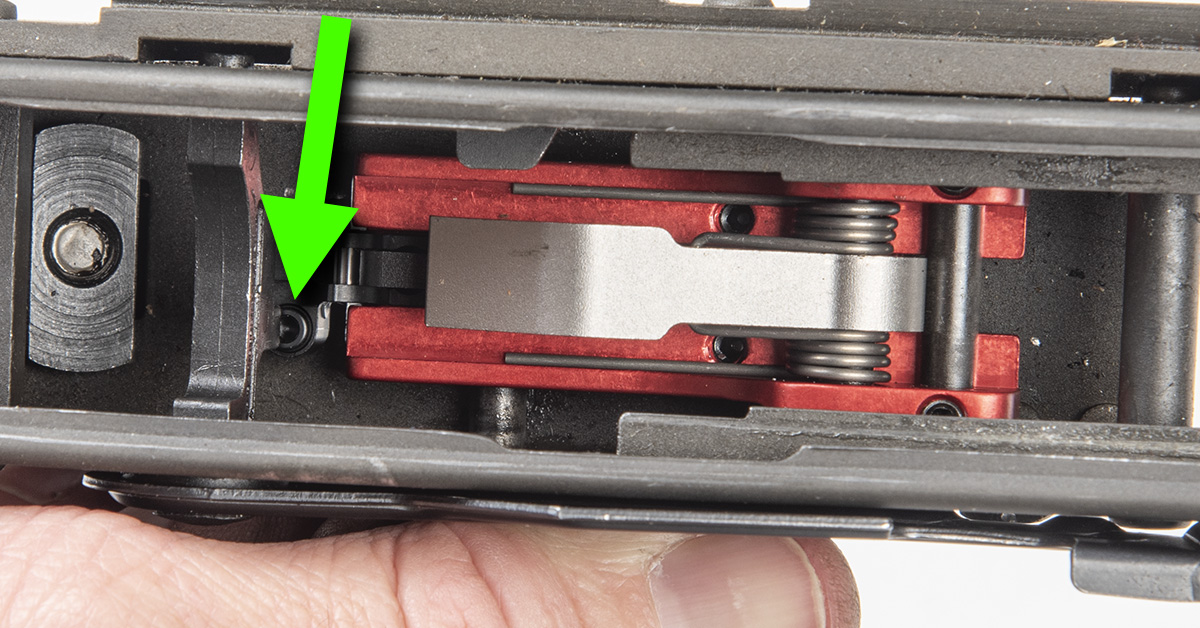

One of the concerns with a drop-in fit is how the unit will work with the safety selector. Timney solved that issue by adding an adjustment screw to the back of the trigger. Raising or lowering the screw ensures a precise tolerance that works with the original factory levers or, as in the case of my Romanian AKM, aftermarket levers such as the Krebs Enhanced Safety Selector.

The AK Drop-In is a single-stage trigger, and it is a far, far cry from the standard AK trigger in terms of performance and feel. I’ll cover that at the end of this article, but for now, let’s look at how easy this system is to install.

Installing the Timney AK Drop-In

The simplicity of this installation is revealed in the tools required. As you can see, it’s not much. All you need is a 1/8-inch punch to move the original pins out and a 5/64th-inch hex wrench for adjusting the set screws. That’s it.

Begin by clearing the rifle and making it safe. Open the receiver by depressing the spring guide rod button and removing the receiver cover.

Push the spring guide rod forward until it clears the stock trunnion and then remove it from the operating rod.

Pull back on the operating rod and remove the operating rod and bolt assembly from the receiver.

Place your thumb against the hammer face and, with the safety selector in the fire position, pull back on the trigger and allow the hammer to move forward into the fired position.

Rotate the safety selector 90 degrees counterclockwise and remove it from the receiver.

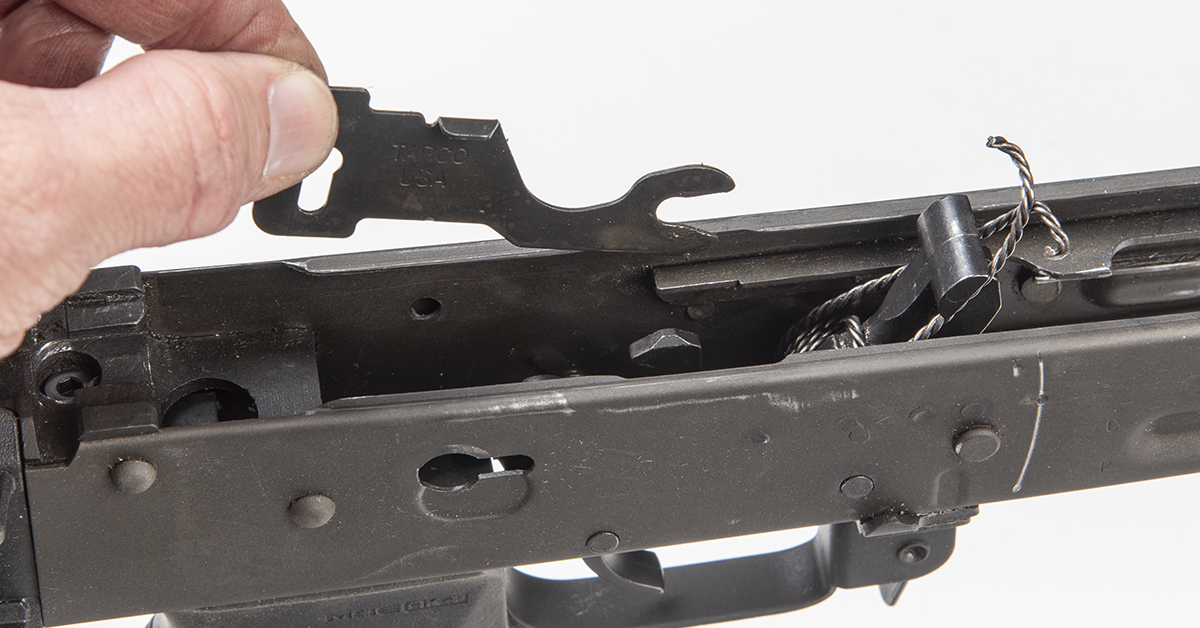

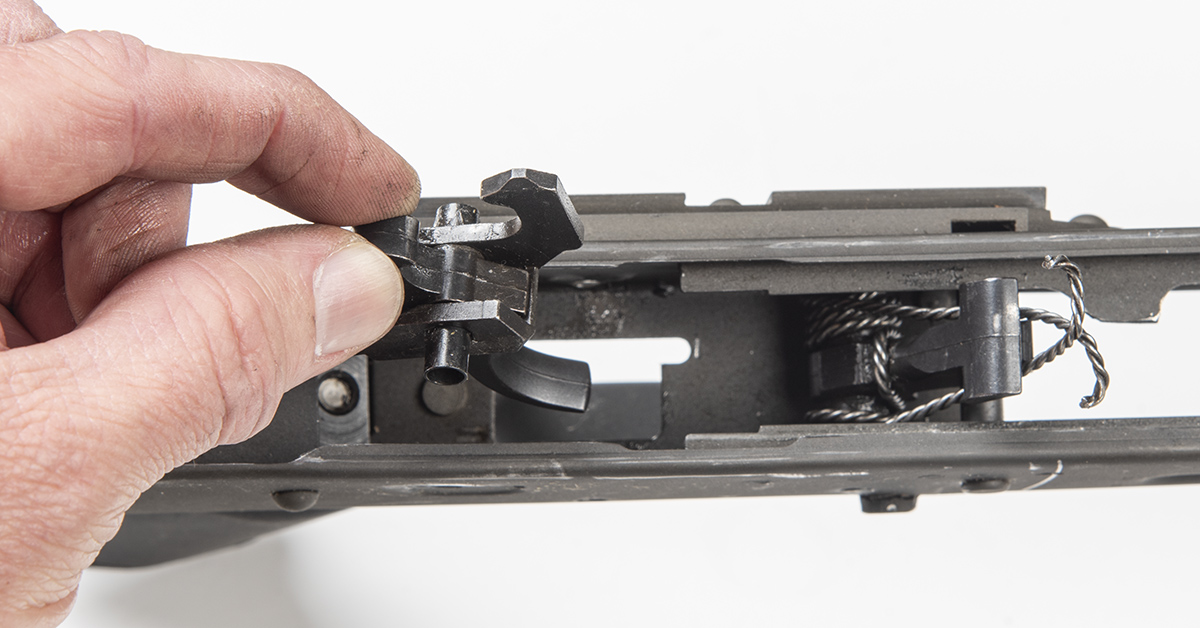

Use the hex wrench supplied with the trigger kit, or another suitable tool, and lift the hammer spring legs up and around to the front of the hammer. Be sure to place them in a crisscross position to prevent the spring legs from slipping off. If one of the spring legs manages to come loose and smack you, you’re in for some hurt.

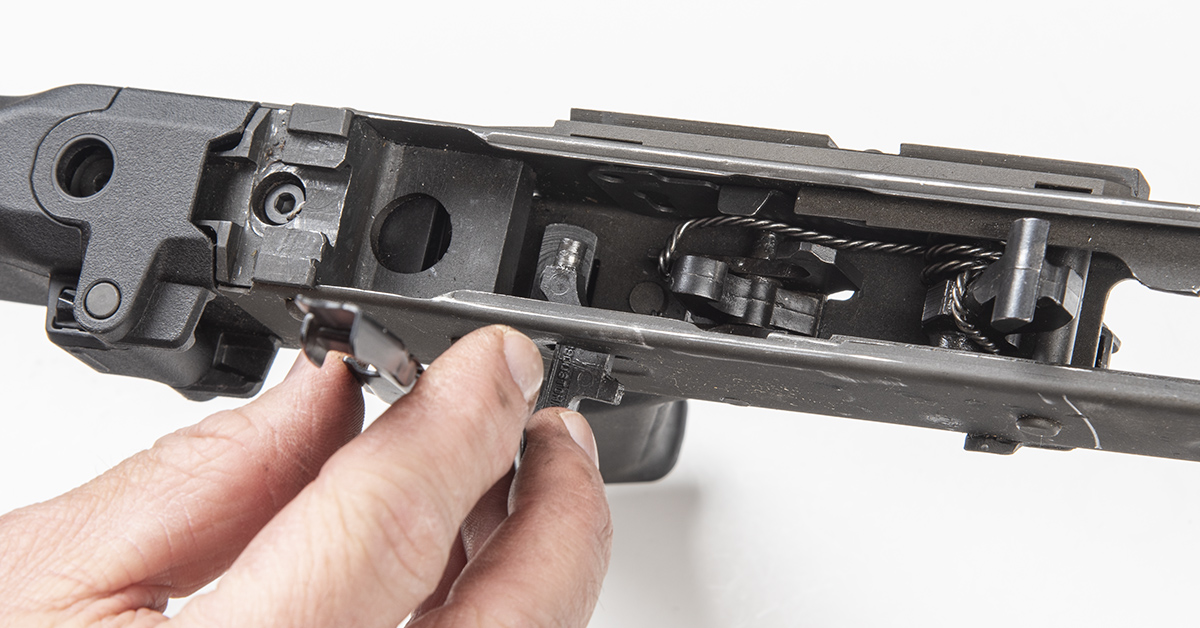

Lift out the hammer/trigger pin retaining plate from the side of the receiver.

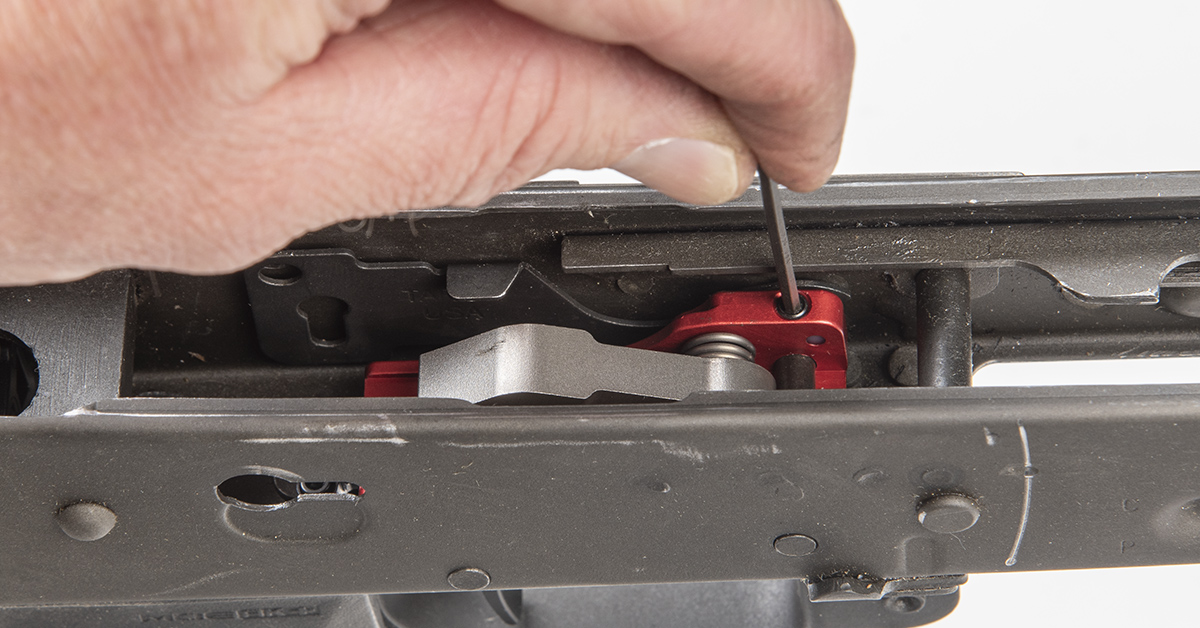

With the 8/32 punch, push out the trigger pin.

Remove the trigger.

Before removing the hammer, it is a good idea to secure the ends of the hammer spring with a small zip tie. Again, if one of these gets loose and whacks your finger, you’re gonna “say words.”

Use the punch to push out the hammer pin.

Remove the hammer and spring assembly from the receiver.

It is also a good idea to cinch the hammer spring to the hammer with a zip tie.

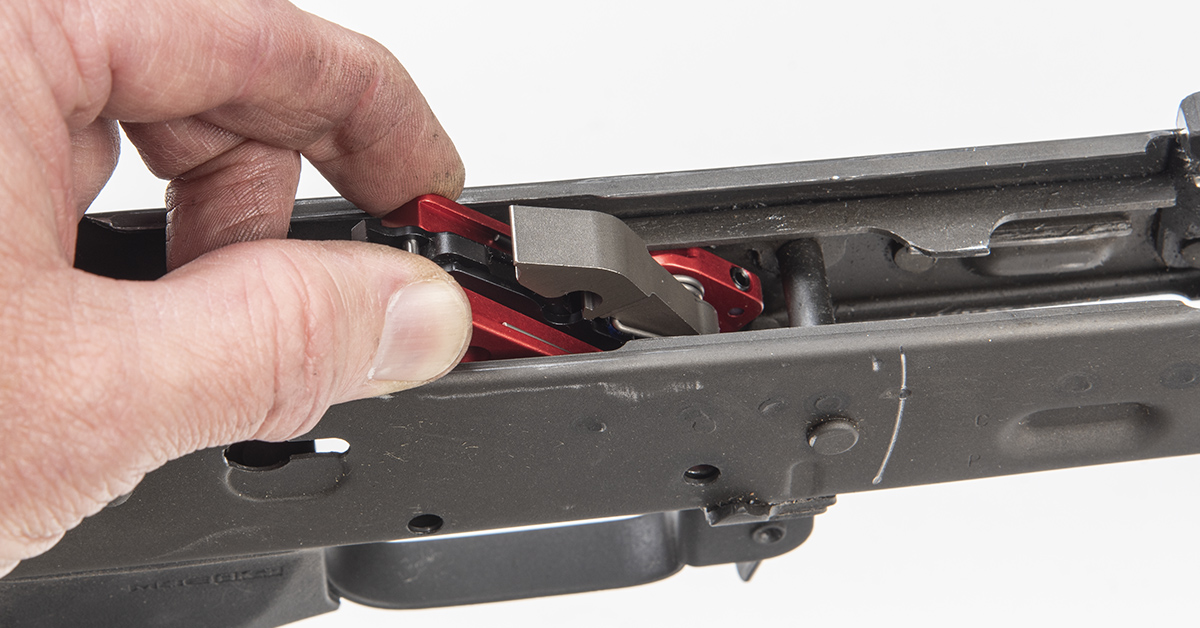

Clean any debris that may have accumulated in the bottom of the receiver in preparation for installing the AK Drop-In unit. The cassette must be rotated perpendicular to the receiver, as shown, to clearance the bolt guide rails.

Once clear, the cassette can be dropped into position in the receiver.

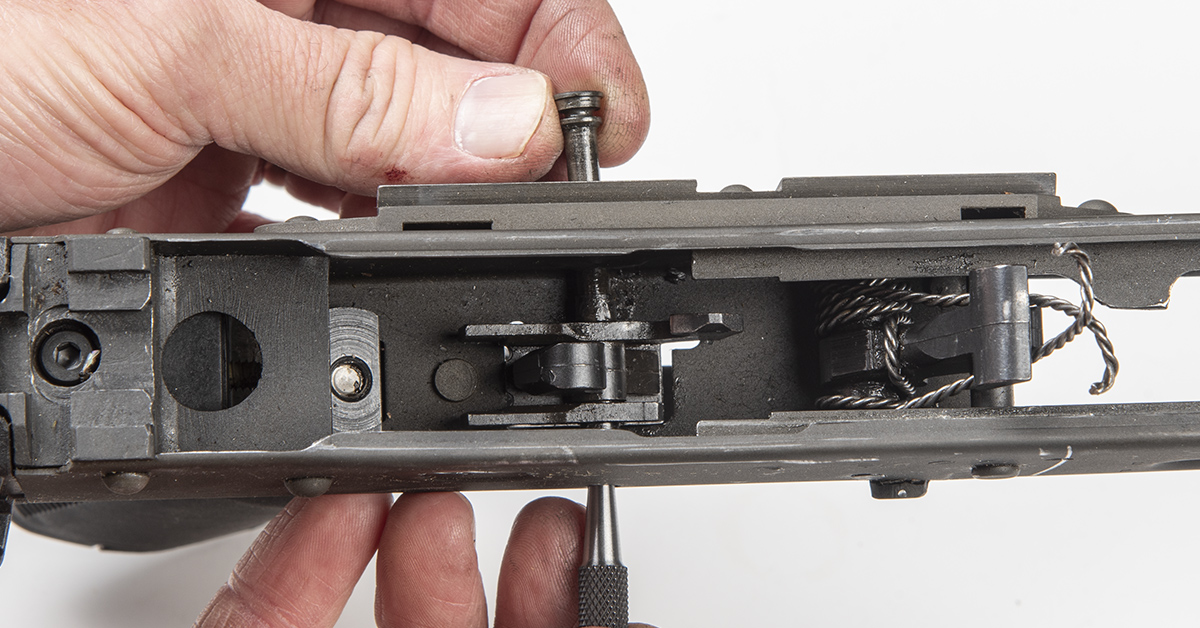

Align the cassette and receiver hammer pin holes and then insert the trigger and hammer pins through both sides of the receiver.

As with many home-built AKMs, my receiver was formed out of a stamped receiver flat. The potential for minor fitment issues with such a receiver build are many. As you can see here, I have an oh-so-slight discrepancy between the receiver pin holes and the trigger cassette pin holes. The trigger pin seated fully with finger pressure while the hammer pin almost made it. I’m talking as little as 0.001 inches if I were to guess. It was just enough that I couldn’t push it in all the way with my fingers.

With a very light tap of the hammer pin, though, it seated nicely.

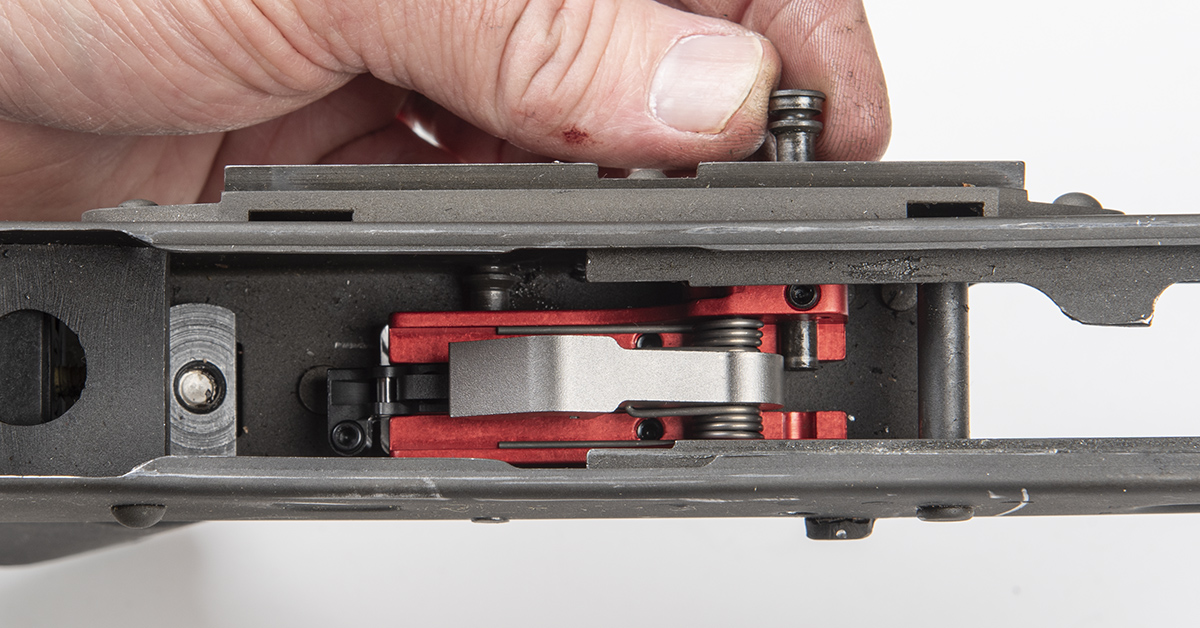

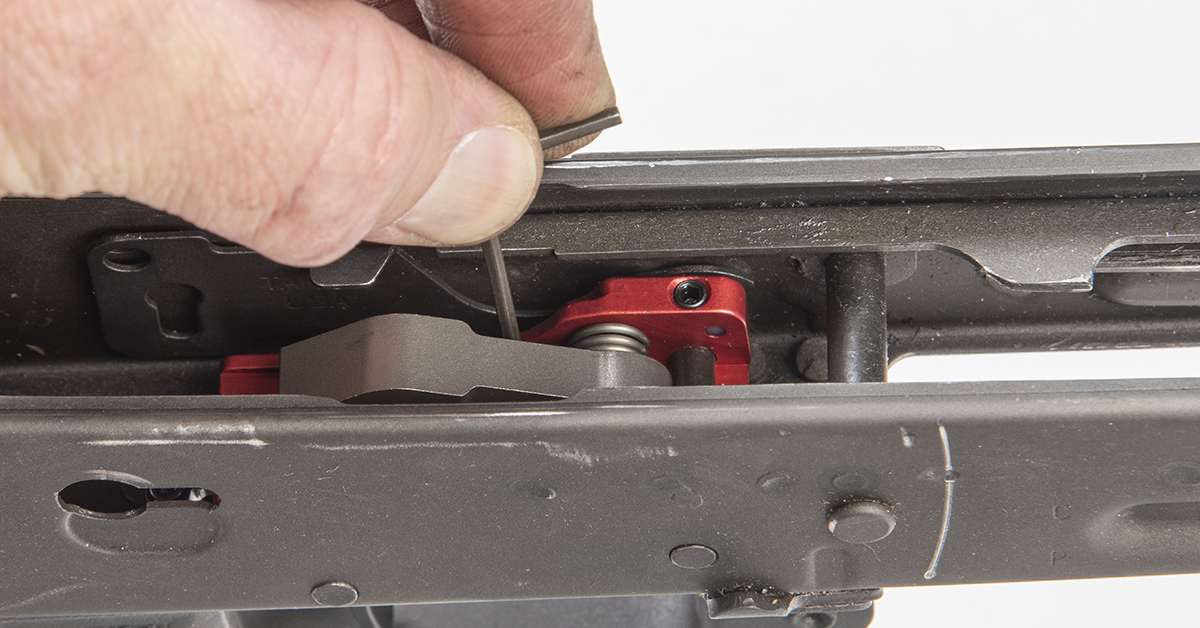

Once the cassette is secured by the hammer and trigger pins, and the pins are fully seated in the receiver, as seen here, it is time to slip the pin retaining plate into position between receiver and the cassette. Keep in mind that the slots in the retaining plate fit into the pin grooves to prevent lateral movement of the pins.

Check to ensure the cassette is centered in the receiver.

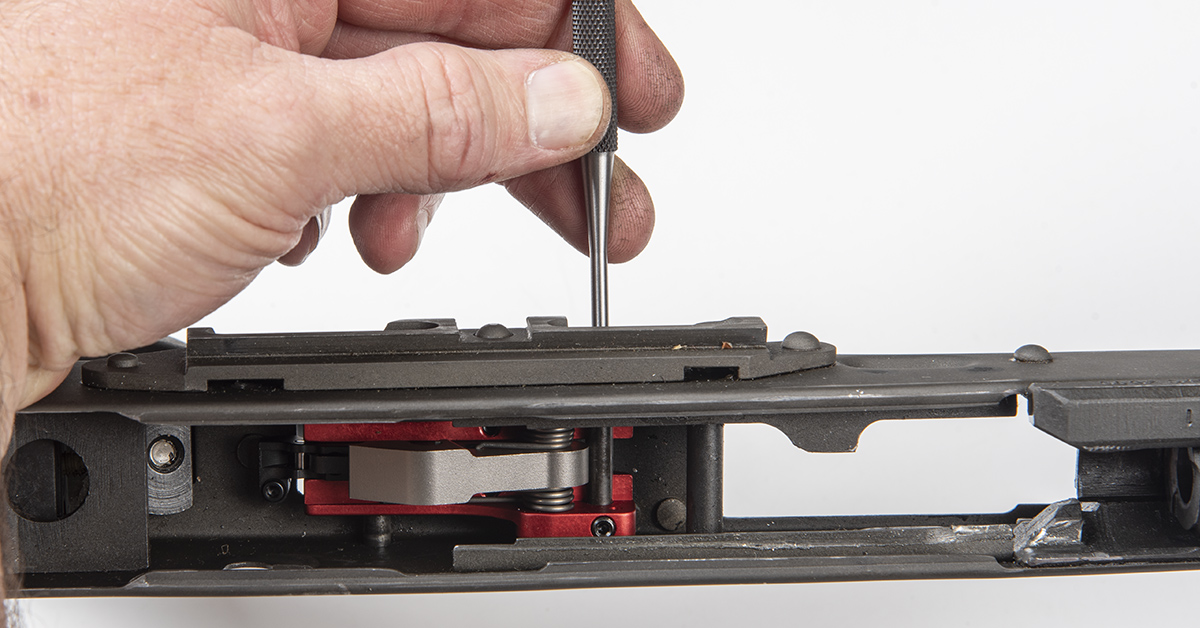

The two forward set screws mechanically lock the trigger housing to the hammer pin. Once the cassette is centered in the receiver, hand-snug the set screws with the 5/64th-inch wrench. This will prevent any lateral shifting of the cassette. Timney calls “snug” 10 in/lbs. If your fingers can calculate that, congratulations!

I will say that the position of the set screws was slightly underneath the bolt guide rails, which meant the wrench had to go in at an angle and couldn’t fully seat into the screw. I could get enough bite to snug the screws; however, use this as a point of caution so you don’t inadvertently wallow out the screw head.

Next, snug up the two center set screws. These apply tension between the cassette and the bottom of the receiver to eliminate any vertical movement of the cassette.

Reinstall the safety selector. Here, you can see that the safety selector is in the safe position. When the AKM’s safety lever is in the safe position, the tab at the bottom of the lever is directly above the AK Drop-In’s safety adjustment screw (arrow). In this position, the safety selector tab arrests movement of the trigger. You want to adjust the screw so that it just clears the safety selector tab when the selector moves between the safe and fire positions and that you cannot pull the trigger rearward when the selector is in the safe position. Once the safety screw is properly adjusted, the installation is complete.

It is now time to perform a function test. Begin by cocking the hammer and placing the safety selector in the safe position. Use your thumb to prevent the hammer from potentially falling forward and pull the trigger to the rear. The trigger should not move and the hammer should not fall.

Next, move the safety selector to the fire position. While maintaining control of the hammer, pull back on the trigger and keep it in its rearmost position. The trigger should move rearward and the hammer should fall. Without letting the trigger move forward, re-cock the hammer.

Once the hammer is cocked (captured by the disconnector), slowly allow the trigger to move forward. You should hear and feel a click as the trigger resets.

If the system failed to pass any part of the function check, reexamine your work to identify and correct the problem.

Finally, reinstall the operating rod and bolt assembly and the spring guide rod. Perform the function check again. If the system failed to pass any part of the function check, reexamine your work to identify and correct the problem. If you cannot identify the problem, contact Timney for guidance.

This completes the function check.

The Results

Following the AK Drop-In installation, I wanted to test the trigger pull weight. Timney rates the pull weight at 3.5 lbs. A ten-pull average on my Lyman scale revealed a 3 lb., 9.5 oz. If that doesn’t hit the consistency mark directly in the X-ring, I don’t know what does. It is that kind of consistency, both in feel and in performance, that we’ve come to expect in Timney triggers across the board and what is vitally important to improving a shooter’s accuracy potential.

Being a single-stage trigger, there is no take up and you really must concentrate to notice any trigger movement before the sear breaks. Simply tug the trigger shoe and the gun goes bang crisply and decisively. For boosting accuracy, this upgrade is a major win as all potential for shot disturbance during trigger travel is removed. Compare that to your long-travel stock trigger system.

Another big plus is that the trigger reset is sooooo short. I measured it to be 2 to 2.5 mm. A good shooter can work this thing fast, accurately, and with exceeding predictability.

AKs…you either love ’em or hate ’em. Few seem to fall in between. If you are in the former camp, the AK Drop-In trigger system from Timney will give you a whole new appreciation for this iconic platform.