Many factors play a part in developing an accurate-shooting rifle for hunting or competition, but this firearm DIY upgrade can make the biggest difference…and it’s easy

by Rob Reaser

All serious shooters and many experienced hunters have had “the WOW! moment” at some point. This was the time when, having been used to shooting only off-the-shelf production rifles, they finally pulled their finger against a premium factory or a precision aftermarket trigger.

If you have never had “the WOW! moment” and are truly interested in improving accuracy and ensuring quick, ethical kills of game animals—especially as those shot distances continue to trend outward—our best advice is for you to stop everything right now and listen. Don’t spend $900 on another scope or drop a dime on an aftermarket stock until you address one of the leading causes of inconsistent shooting performance…the trigger.

We can go down many rabbit holes when discussing triggers, but the subject really isn’t that complicated. Once you understand how a trigger’s performance, for better or worse, impacts the shot and then you have the opportunity to shoot a rifle with a quality trigger, you’ll get it. After that, you probably will never again be able to settle for a factory trigger in your hunting rifle…or any rifle, for that matter.

The Trigger Influence

When we talk about shifting from a factory trigger to a precision trigger, we’re not “adding to” the equation as is usually the case with many aftermarket products. The purpose of a precision trigger is to take away one of the key causes of inconsistent shot placement (the other being barrel/ammunition load compatibility). That “take away” is shooter-induced shot disturbance.

Firearm manufacturers largely engineer their trigger systems for a general-purpose audience. Translation: they develop their triggers for maximum safety when used as designed by the average shooter and the conditions for which the firearm is intended to be deployed. This balancing act often results in triggers with a long-ish pull length, relatively heavy pull weight, and a less-than-crisp, who-knows-when-it-will-happen sear break.

And therein lies the problem.

For example, you set up on your rifle—field position, bench rest, field rest…whatever. The rifle is aligned on target with a natural point of aim. Everything is set to pull the trigger and send a bullet downrange. Discounting any body movements that can disturb the sight picture (which you can’t discount in the real world), such as your breathing cycle, pulse, and grip tension, you should, theoretically, be able to pull the trigger straight back without disturbing the shot (moving the rifle). By virtue of that long, heavy, and possibly rough factory trigger performance, though, you are likely to disturb the shot during the trigger squeeze. Such shooter-induced disturbance means the bullet point-of-impact is going to be inconsistent from one shot to the next. It might not be a lot, but it is definitely going to be there. And the longer the shot, the more pronounced the point-of-impact deviation will be. That’s bad news for hunters needing to take long pokes at critters.

Why does this happen? It’s simple biomechanics.

Starting with the trigger pull weight, the harder the trigger is to pull back, the more muscle tension is required to make the shot. Thus, the more “squeeze” you must apply to the trigger the more likely it is that you will be off target when the shot finally breaks because you are inadvertently moving the rifle, even if only slightly.

Now, compound that with the trigger’s length of pull, or the distance between the trigger at rest (in the forwardmost position) and the sear break (when the trigger releases the hammer, allowing the hammer to move forward and strike the firing pin). The longer the pull and the harder that pull is, the greater the chance of introducing hand and finger torque, which could upset the sight picture (aim) and send the bullet somewhere other than where you were intending it to go.

Finally, there is the nuanced nature of the sear break.

The sear is the component (or components) that uses a short surface-to-surface interface with the hammer to hold the hammer back and to keep it from striking the firing pin until the trigger is pulled. Depending on the geometry of the sear, its material construction, and its friction coefficient, sear movement can be long and rough, short and “crisp,” or somewhere in-between. Triggers exhibiting a long and rough or “gritty” sear engagement can induce significant shot disturbance because it prevents a smooth trigger pull and a decisive release of the hammer, allowing for additional body movement to upset the shot. For this reason, a great deal of attention is placed on a trigger’s sear performance, whether you’re talking about a rifle, a handgun, or a shotgun, and it is usually the primary factor in either amplifying or minimizing shooter-induced shot disturbance. The ideal is a short and smooth sear travel.

Factory vs. aftermarket

This, of course, begs the question, “Why don’t firearm manufactures produce triggers with short, crisp breaks?”

It’s not that some of them don’t or that they can’t. Several factors influence the quality of a factory production trigger. The more precise and refined the trigger, the more it costs to produce. This holds true for most anything in a production environment. The other major influencer is safety. This is not to imply that short, “breaks like glass” triggers are less safe than heavy, long and crunky triggers. Rather, long and crunky heavy-pull triggers have a greater span in time/length of travel between the moment the trigger begins to move rearward and the sear break. That more deliberate action required to pull the trigger and release the hammer is something of a “safety buffer” that has more to do with the operator than with the inherent safe design of the trigger.

Again, we must keep in mind the parameters of mass production and the mass consumer. Triggers, as with gun stock dimensions, are generally built within mass production constraints for the “one-size-fits-most” mass consumer. When you wish to move to a trigger that eliminates those inherent negatives, the aftermarket is the place to go.

One company that has been at the forefront of precision triggers since the middle of the last century is Timney Triggers. In fact, Timney has been leading the precision trigger charge for the last 75 years, beginning in 1946 when Allen Timney developed triggers to retrofit the WWII-era Springfields, Enfields, and Mausers favored by many hunting GIs who made it home from the war.

In the decades since, the engineers at Timney have refined designs and leveraged new materials and manufacturing processes to deliver increasingly precise triggers for an ever-growing range of shooting applications, such as bench shooting, fast-action competition, and long-range precision. The lessons learned from product development across all these categories translate directly into the Timney triggers suited for hunting rifles—everything from Arisakas to Winchesters and all the most popular rifle brands in-between.

Since the Remington 700 is arguably the most common centerfire rifle spanning hunting and competition applications, we’ll continue this discussion around Timney’s triggers designed for this proven platform.

Important Trigger Considerations

Once you start getting serious about improving your firearm and your shooting skills, you’ll realize that triggers are quite personal. That elusive, just-right “feel” varies from shooter to shooter, and several factors play into that, such as the trigger shoe profile (flat, curved, broad, skinny, overall geometry), pull weight, pull length, overtravel, sear engagement, and so on. This is why top competitive shooters may go through several different triggers before settling on one that meets their specific needs and shooting style.

That said, there are two primary characteristics of an aftermarket trigger that every shooter looking to upgrade their rifle’s performance should consider.

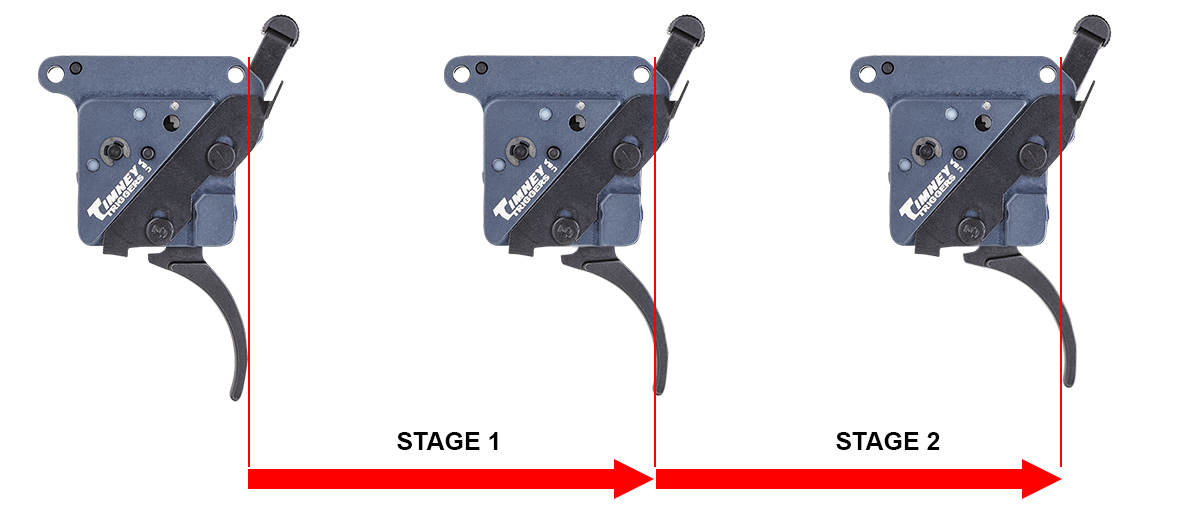

Single-Stage vs. Two-Stage – Historically and conventionally, production rifle triggers are of the single-stage flavor. With a single-stage trigger, the action is simple: pull back on the trigger until the gun goes BANG. All the trigger’s pull weight is applied from the start of the trigger pull until the sear breaks and the hammer slams against the firing pin. It is effective, to be sure, and when we’re talking about an average-quality production rifle trigger, it is perfectly adequate for typical hunting distances.

When we shift to longer distances and the need for greater trigger control becomes essential is where the mass-production single-stage triggers begin to falter. As we mentioned earlier, that long, hard pull is going to induce shot disturbance. That is not to say all single-stage triggers are problematic. We’re talking only about the average mass-production single-stage trigger.

A precision aftermarket single-stage trigger absolutely hits the highwater mark in terms of shot disturbance mitigation. What you will most notice when comparing a mass-production single-stage to a precision aftermarket single-stage trigger is the “creep,” or length of real and/or perceived trigger travel before the gun fires. Most mass-production triggers will have a noticeable creep before the sear break. A precision aftermarket trigger will most likely break crisply and cleanly as soon as you apply the threshold pressure (trigger pull weight), and you will probably never detect any trigger movement before the gun fires. This is how a quality trigger adds to the accuracy formula—you go from zero to BANG with maximum control of effort and timing.

By contrast, a two-stage trigger introduces, as the name implies, a second stage in the trigger pull cycle.

The first stage is the initial rearward trigger travel, or take-up. This stage is lighter than the final, or combined, trigger pull weight. At the end of the first-stage take-up, the trigger hits a “wall” and stops rearward travel at that applied pull weight. The trigger is now at the beginning of the second stage and only an additional trigger pull effort (against the heavier weight) is needed to release the sear and allow the hammer to strike the firing pin.

With a two-stage trigger, the first stage allows the shooter to set up for the shot. The shooter will establish the sight picture and take up the first stage of the trigger pull, knowing that the next tug on the trigger will fire the gun. Discovering how to incorporate this two-stage process with your breathing cycle takes practice.

Some shooters take up the first stage, hit the wall, and then pull through the first stage at the bottom of the next or subsequent pause (the extended exhale) in the breathing cycle. Others prefer to take up the first stage and pull through the first stage across the extended breathing pause.

Regardless of how you incorporate the two-stage pull into your breathing cycle, the two-stage trigger offers the confidence of knowing exactly when the gun will fire.

Another advantage for the hunter is the ability to take up the first stage and then come off the trigger without initiating any sear movement—a big field safety advantage.

Consider for a moment. You are on a mulie or elk that is 300 or 400 yards out. You set up for the shot, the adrenaline is flowing, you start to pull the trigger, and right before the break, the animal moves. You let off the trigger.

With a single-stage factory trigger, that sear may have moved slightly along the hammer. Did the trigger return spring move the sear back to its original position or is it still partway toward the break? If the latter, then you may have a problem because the next time you go to pull the trigger, the trigger may break before you expect the shot. That can lead to a miss at best or a potentially dangerous situation at worst.

With a precision two-stage trigger, on the other hand, you can be fairly confident that you can let up on the trigger after taking up the first stage, knowing that the sear has not budged.

On the flip side, a two-stage trigger may be problematic for some hunters, depending on the trigger pull weight of the final stage. Two-stage triggers are wonderful when taking slow, deliberate shots. When the action speeds up and a quick shot is called for, adrenalin-fueled excitement could cause the shooter to inadvertently pull through the first stage and execute the shot before they are ready—especially if the second stage pull weight is relatively light.

So, how does this boil down for the hunter? If close-range (under 200 yards), potentially quick shots are the likely scenario for your gun, a precision single-stage trigger may be your best bet. If, though, you expect to take way-out-there pokes, as in a western hunting environment where you have the time to set up for the shot, then a two-stage trigger may be the ticket.

Adjustability – High-quality precision triggers like those offered by Timney almost always offer some measure of adjustability. These adjustments can include trigger pull weight, overtravel, and sear engagement.

Trigger pull weight adjustment allows you to set the pull weight to a level that is optimal for your shooting style and the application. Usually, this is a range of two to four pounds of adjustment for a given trigger. Hunting-oriented triggers typically have an adjustment range from 2.5 to over 4 pounds. A target- or competition-focused trigger will lower that range, with the low end of the pull weight measured in ounces up to a couple pounds or so.

For a hunting trigger, two to three pounds is the lower end of the weight scale most hunters are comfortable with. This weight is light enough to deliver the desired accuracy performance yet heavy enough to work in a high-adrenaline field environment. Whatever the case, being able to adjust the trigger pull weight is desirable for anyone looking to customize their trigger for maximum accuracy.

Sear engagement is another adjustment that is sometimes found on premium-grade triggers. This adjustment changes the amount of surface the sear must travel before releasing the hammer, taking a “light” trigger to “extra light.” For the most part, this is something you probably won’t (or shouldn’t) mess with on a hunting rifle trigger. In our opinion, and in the opinion of most experienced hunters, having a touchy hair trigger is not a good recipe in the hunting fields.

The final trigger adjustment common to aftermarket triggers is overtravel. Overtravel refers to the distance a trigger moves between the sear break and the end of the trigger’s rearward range of motion. Long overtravel in a trigger may, for some shooters, allow the shot to be disturbed in that micro-moment between the time the sear breaks and the time when the bullet leaves the barrel. By shortening the overtravel, you can narrow the window that the rifle can move (assuming you practice good follow-through) after the hammer falls. This is a feature that is most practical for the precision long-range shooter.

Installing a Timney Remington 700 Trigger is Easy!

As you can see, the trigger can have a significant influence on shot placement. Further, the not-so-subtle nuances of precision aftermarket triggers can seriously boost the accuracy potential of a rifle by reducing or eliminating shooter-induced shot disturbance. The question isn’t whether a precision, adjustable trigger will improve your shooting performance. In almost every instance, it will. The question is, “What are you waiting for?”

Continuing with the Remington 700 platform, swapping the factory trigger for an aftermarket model like those offered by Timney is about as easy as it gets. Let’s take a look…

Two screws secure the barreled action to the stock. Remove the bolt and then remove these screws and separate the barreled action from the stock.

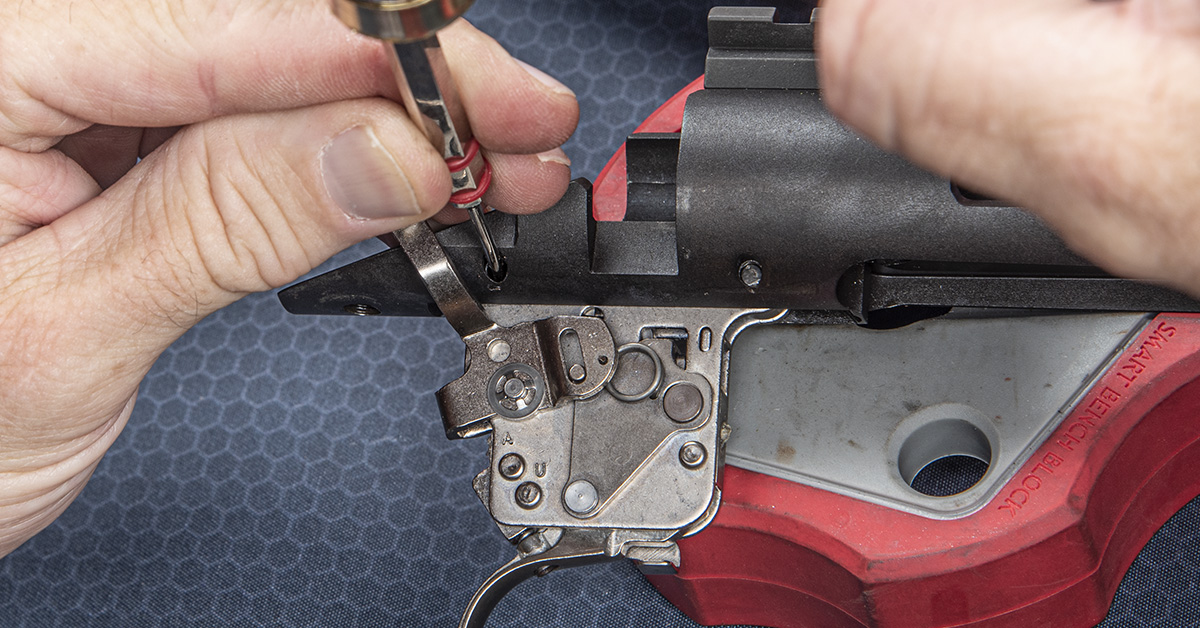

The trigger is secured in the action by two pins. Place the action on a bench block and, using a small punch and hammer, tap the rear trigger pin from right to left just until the pin clears the trigger mechanism. Do not push the pin all the way through the action so as to keep the bolt stop lever and spring in place. If you push the pin all the way through, the bolt stop lever and spring will fall out and these are a bit aggravating to get back in place. Their removal is not necessary to replace the trigger.

Flip the barreled action over. Here, you can see the rear trigger pin is partially out of the action and retaining the bolt stop lever and spring (right side). Now, tap the front trigger pin from left to right until it clears the trigger mechanism. Again, you do not have to push the pin completely out of the action.

The factory trigger can now be removed from the action. Note that both trigger pins are still in the action.

Installation of the Timney trigger is the reverse of the removal process. Start with the front trigger pin and tap it evenly into the action.

When tapping the rear pin into place, be sure that the top sear is positioned underneath the pin. If not, the bolt cannot be inserted into the action.

A trigger pull scale, such as this Lyman unit, is a recommended investment if you plan to do much trigger work. Here, we see that the pull weight of this Timney HIT single-stage trigger is set for 9 ounces. That’s a NO-GO for this hunting rifle!

Adjusting the trigger pull weight on the Timney is a simple matter. Turn the adjustment screw in for a heavier pull or out for a lighter pull.

For this .270 deer rifle, a 2-lb. pull is just right.

Most Timney triggers also allow for overtravel adjustment. This is the amount of trigger travel between the sear break and the limit of rearward trigger movement. A short overtravel can help reduce or eliminate shooter-induced shot disturbance after the shot breaks.

And that is all there is to upgrading your Remington 700 trigger with a precision aftermarket unit like those available from Timney Triggers.