There is nothing more satisfying shooting steel targets. If you are ready to make an investment in some range fun and elevate your practice sessions, here’s what you need to know.

by Barb Melloni

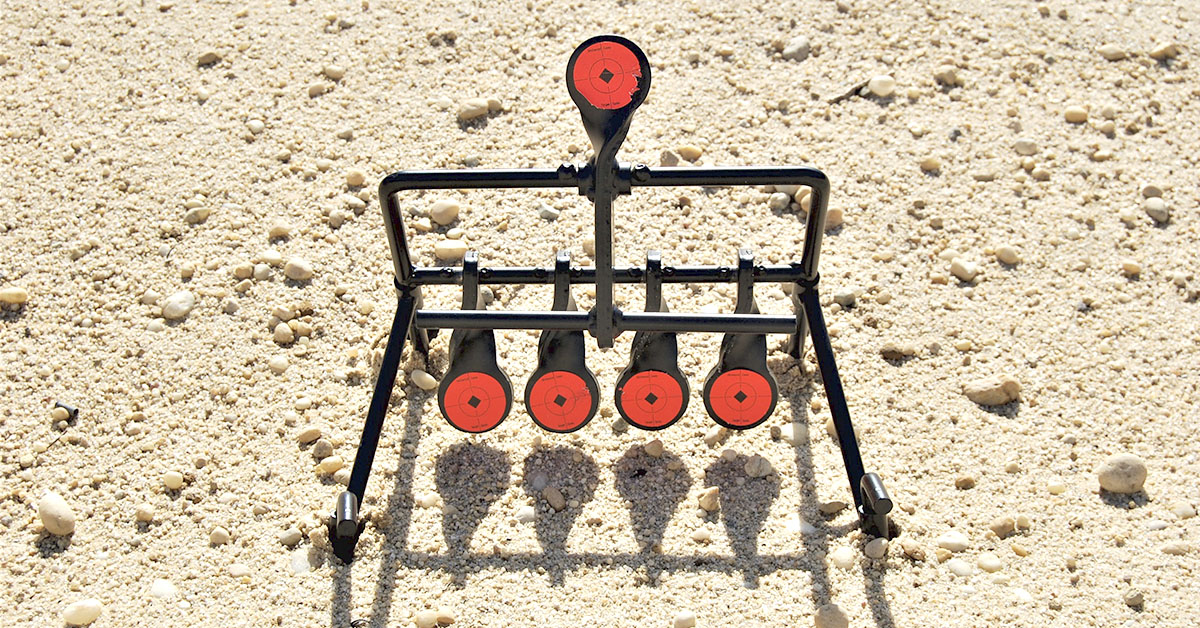

Regardless of the shooting discipline(s) you enjoy, there’s no denying that steel targets are among the most popular. They come in a plethora of shapes, sizes, and reactions offered, and there is instant gratification when that “PING” announces you have landed your shot. Steel targets are also easy to deploy within a safe shooting environment. But before you decide to make the investment, there are some things you need to know.

What is AR500?

If you’ve ever looked into steel targets, you’ve likely come across the term “AR500.” The “AR” in AR500 stands for “abrasion resistant” and the “500” refers to what is called the Brinell Hardness Number, or BHN for short. As the BNH level of a piece of steel increases, so does its hardness level. This means steel classified as AR500 is tougher than AR400, and so on. Steel targets are available with hardness levels ranging from AR350 up to AR700. AR500 steel provides a high level of hardness, which produces a consistent pattern of bullet splatter when the target is properly mounted and angled. This would not be possible with softer steel, as the bullets would damage the plate and cause cratering within the target. The resulting uneven surface would then send bullet splatter every which way.

The high hardness level of AR500 makes it one of the most popular options for target steel, with different thicknesses dictating the ideal caliber and load that can be slung its way without damage. The most common options, as far as thickness goes, include 1/4-inch, 3/8-inch, and 1/2-inch. Considering which cartridges you plan on slinging downrange; you can use that knowledge, along with varying thickness options available, to find the most cost-effective option for your needs.

Steel Thickness/Caliber Compatibility and Distance

As mentioned, there are three common types of target thicknesses available to consumers: 1/4-inch, 3/8-inch, and 1/2-inch. When choosing the most cost-effective option that is best for you, it is essential to look at what calibers you plan on using. The following recommendations are the minimum.

Taking the popular 22LR, as an example, you can certainly use half-inch thick steel targets, but the thinner, quarter-inch AR500 will also work while presenting a lower cost and lighter weight (making it easier to tote around the shooting range). Placed at a minimum distance of ten yards, this thickness and caliber combo is considered a safe setup for your range session.

There are also AR400 targets available for this popular rimfire option, but for this discussion, we’re going to stick to AR500 for all examples and comparisons.

Moving up in caliber, we have the 3/8-inch AR500, which is the minimum recommended thickness if you plan on shooting centerfire handgun rounds such as 9mm, .45ACP, and so on. Those training with shotguns can also use birdshot and buckshot on this same steel. When using 3/8-inch AR500 steel with centerfire handgun and birdshot/buckshot rounds, the target should be placed at a minimum of ten yards from the shooter. Using that very same 3/8-inch steel, you can place it at a minimum distance of 100 yards for use with centerfire rifle rounds such as 5.56, .308, and even shotgun slugs.

For those shooting larger centerfire rounds such as .300 Win. Mag., .338 Lapua, and similar, there is a half-inch AR500. The minimum distance for this caliber/thickness combo is also 100 yards.

Mounting Steel

The most effective way to prevent ricochet is to angle your target downwards approximately 20 degrees or so from vertical. This is necessary to ensure that bullet fragments are directed toward the ground instead of coming back toward the shooter,

As for mounting methods, there are a few different options to choose from — some of which include chains, rubber straps, and a variety of brackets paired with 2x4s or conduit. If you happen to be using chain or rubber straps for hanging your target, you’re going to want to utilize some heavy-duty nuts and bolts, with beefy carriage bolts being a popular go-to. You may want to check with your local fire department to see if the station has any fire hose they are getting rid of, as this makes a very durable solution for target hanging.

Depending on where you purchase your targets, they may or may not come with a bracketed mounting solution from the manufacturer. These are great options that take the puzzle work out of mounting your targets. All the options mentioned will need to utilize some sort of base that may include one or a combination of the following: steel target base, lengths of 2×4, or pieces of conduit — all of which are easily found at your local hardware store.

What Else?

There’s not much upkeep and maintenance required when it comes to steel targets. Simply apply a fresh coat of paint after each shooting session and you’re good to go. Ensure your straps, mounting hardware, chains, and stands are in good condition and replace any necessary pieces when they present a safety hazard.

What you do want to keep an eye out for over time is excessive cratering on the target. While minor pitting is to be expected with continued use, you can still use the target, but it is suggested that you place it at a further distance to protect against ricochet. Such well-worn targets often get a new lease on life when placed at extended ranges where there is zero threat of target splash back.

Other than that, when handling steel during installation or transportation to the range, it’s always a good idea to wear a pair of work gloves to prevent cutting yourself on sharp edges or bullet fragments.

- Budget Import Shotgun Clones Worth Your Money - January 16, 2026

- TESTED: Heritage Badlander Nickel Double-Barrel - September 30, 2025

- REVIEW: Mossberg 990 AfterShock - August 25, 2025