Drop-in parts are usually easy to install, but close-tolerance, accuracy-inducing components often take hand-fitting by a seasoned gunsmith. Choose your path wisely.

by Bob Campbell

A quick check of my notes and memory confirms I have built perhaps ten to twelve 1911 handguns over the past few decades. I have also fitted Browning Hi-Power, Beretta 92, and GLOCK barrels. This was accomplished without extensive tooling. No drill press or lathe rests in my modest shop. Just the same, I have accomplished much. Fitting first the excellent Caspian frame and slide and even building budget-grade pistols from Essex parts kits was enjoyable and a pleasant pastime. The great majority of parts used have been drop-in parts.

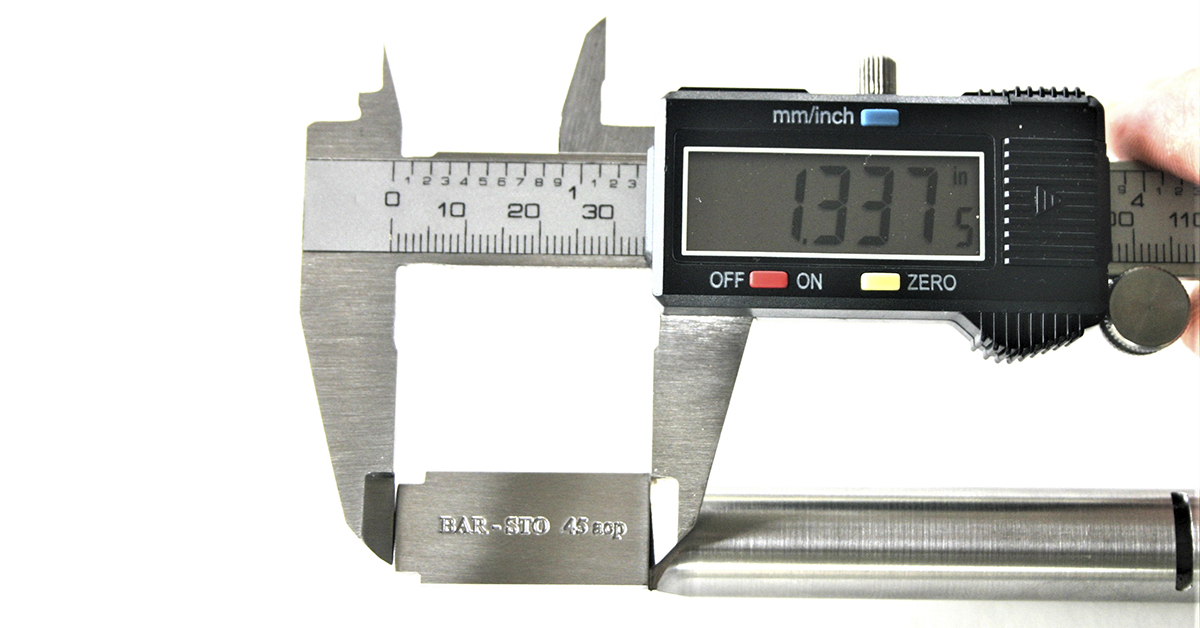

Folks working primarily with the GLOCK pistol and enjoying its easy compatibility may not quite realize what 1911 shooters go through. Fitting a trigger bow or polishing a grip safety is par for the course. You cannot reasonably expect a handgun manufactured for over 100 hundred years and by more than a dozen makers to be consistent in every detail across the board. Some make a pistol as cheap as possible; others wish to manufacture a work of art. The wonder of it all is that it is possible to fit a modern Bar-Sto barrel into practically any 1911 ever made. It just takes time and a bit of effort. Perhaps even some finesse. It isn’t all about building a custom gun or a one-of-a-kind jewel. Sometimes you must replace a well-worn or broken part. When you do so, a basis for procedure I have followed should come in handy. Most of this work is accomplished with drop-in versus gunsmith-fit parts.

I would hazard that drop-in parts and building your own 1911 isn’t as popular as it once was. After all, the affordable Rock Island Armory 1911 is less expensive (with inflation figured in) than the purchase price of an Essex frame slide and parts so long ago. It isn’t cost-effective to build a GI gun. Top end pistols are better than ever — but the Caspian frame and slide are still a good standard for building a one-at-a-time 1911.

Today Wilson Combat offers excellent parts with a high degree of precision. We have it better than ever.

Let’s look at the story and see if it is worthwhile for you to use these drop-in parts or instead choose a gunsmith fitting required part.

Drop-In vs Gunsmith-Fit

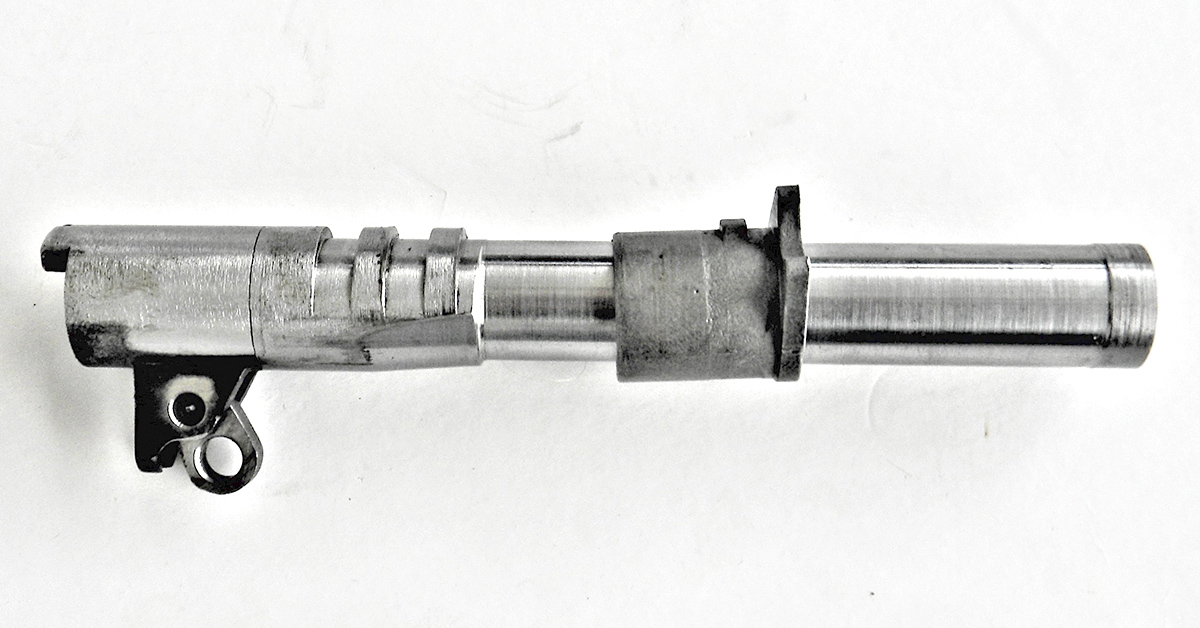

A drop-in part is factory tolerance and will drop into the frame or slide as a factory part would. But then there is some fitting needed in the better class of 1911 handguns at the factory. Gunsmith-fit parts, in particular barrels, are made to slightly greater dimensions than drop-in parts. They are useful in a wide variety of 1911 handguns. They will demand a bit of file work and polish to fit. As a result, they are tight and snug, and this should enhance accuracy.

A tightly fitted part will return to battery in exactly the same place time after time with a high degree of precision. This results in less eccentric wear and greater accuracy. If fitted correctly, reliability isn’t compromised.

I have fitted GLOCK barrels with oversize dimensions that demanded fitting. I am not certain if such a thing is even available today. A Bar-Sto drop-in barrel for the GLOCK enhances accuracy considerably. Perhaps the most accurate GLOCK pistol I have fired is a modified G22. Originally, the pistol demonstrated casual accuracy at best. A .357 SIG barrel in the .40 GLOCK provided stellar accuracy. The sights were changed as well. I have also enjoyed excellent results with Bar-Sto barrels in the Hi-Power 9mm. In each case, accuracy was enhanced as a result of precision fit and rifling.

History of Gunsmith-Fit Parts

The background of these precision parts is simple enough. When competitors demanded greater accuracy from the 1911 for National Match shooting, Army gunsmiths welded up the barrel until it would not ‘drop in’ the slide. They then ‘gunsmith-fit’ the part until the pistol was tightly fitted and accurate. Original military specifications called for acceptance of a 1911 that would shoot a five-inch five-shot group at 25 yards and a ten-inch five-shot group at 50 yards. While most GI guns were a little more accurate than this standard, that type of accuracy would not win a shooting match.

Drop-in barrels for the European pistols — SIG and GLOCK — not only enhance accuracy, but they also allow caliber changing between the .357 SIG and .40 S&W by simply swapping the barrel. Quite possibly the only pistol I have experience with that did not benefit from a drop-in barrel was the SIG P220 — already a very accurate .45 ACP. A big advantage in the GLOCK is that conventionally rifled barrels are now able to safely provide real economy with lead bullets. Polygonal-rifled barrels are not compatible with lead bullets…even hard cast lead. Besides a Bar-Sto, True Precision barrels offer improved accuracy with any loading.

With the 1911 type, occasionally a drop-in barrel needs minimal fitting. The barrel hood must be carefully fitted by polishing away material. The locking lugs may be overlarge as well. A simple rule of thumb is to check fit with a slide stop. With the slide removed, seat the barrel properly in the frame, complete with a link. Insert a slide stop into the slide stop opening and through the link. If the barrel moves upwards, then some fitting will be required.

When purchasing a drop-in barrel, you are ahead of the game to order a complete barrel and barrel bushing set. The outer diameter is OK if the old bushing fits your new barrel.

If you decide to build a 1911 using a special frame and slide, it’s best to order each from the maker. As an example, Wilson Combat offers their frame and slide components as separate parts. I have used these parts in 1911, SIG P320, and GLOCK pistols. Be certain to use quality parts. Not saying a new maker may not offer quality gear — but then they may not be there tomorrow. Novak’s, Nighthawk Custom, Nowlin Arms, Ed Brown, and Wilson Combat are among the parts you can count on. When they were available, I found Rock River Arms’ slide and frame dimensions excellent.

Series 70 pistols or MILSPEC handguns, as they are referred to, are the easiest to work with. Slides and frames accept most any part and often slides, frames and barrels are interchangeable. Tightly fitted pistols such as the Les Baer are less likely to accept standard parts. And they should not. This is why gunsmith-fit oversize parts are manufactured. As a rule of thumb, the less expensive handguns from the Rock Island and up to the Springfield MILSPEC accept most aftermarket parts. But not all aftermarket parts are drop-in. While gunsmith-fit parts such as oversize barrels and barrel bushings are available, some parts must be oversize and all demand fitting.

One part that demands fitting is the slide lock safety. Many shooters do not realize the slide lock safety and its bearing on the disconnect influences the trigger action. It wouldn’t make sense to ruin a crisp trigger action with a poorly fitted slide lock safety. The indent of the slide lock safety must be tight. This prevents the safety being pushed off inadvertently and prevents the safety from being easily snapped on during recoil.

Another part that must always be fitted is the 1911 extractor. I have used the Wilson Combat Bullet Proof extractor for some time. A 1911 relies upon the extractor for proper function in the feed cycle. A slight bump on the extractor is designed to offer a good tight fit once the piece is properly fitted and polished. If not properly fitted, an extractor will “clock.” This means the extractor will turn in its tunnel. A tight fit ensures long life and good function.

Trigger Action

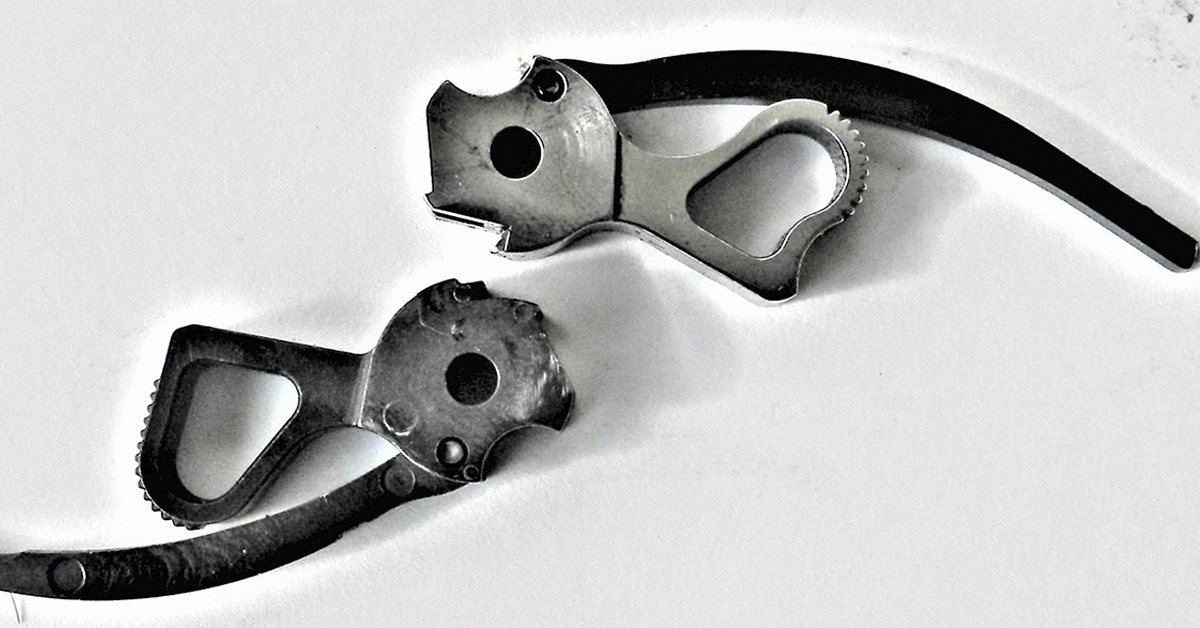

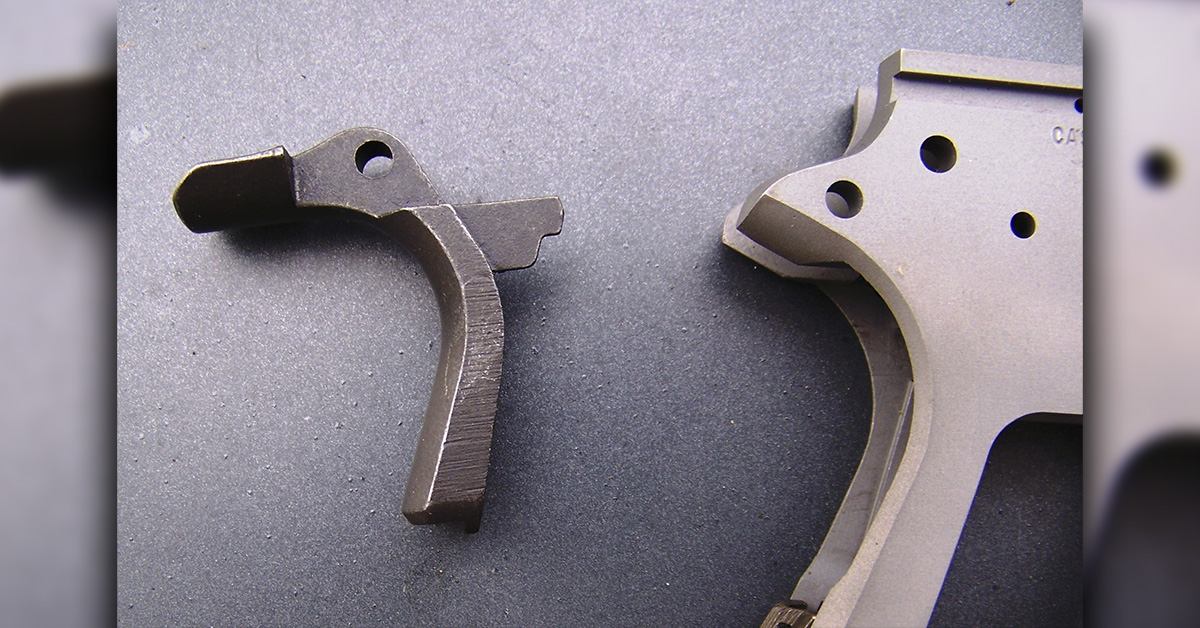

As a rule, I do not recommend a 1911 aftermarket trigger action for personal defense use. For competition or range fun, the sky is the limit. An exception would be a full replacement with a matched set — sear, disconnect, and trigger — from Nighthawk or Wilson Combat.

A ‘trigger job’ was done by polishing parts. While making the part smoother is a good thing, extreme care must be taken to prevent reducing contact surface. This isn’t a good idea with quality steel parts and a very bad idea with MIM parts. Once the covering of a MIM part is filed away, wear proceeds rapidly. Cast parts also wear quickly if filed and polished. The better course is to purchase a complete trigger action from Wilson Combat, Ed Brown, or Nighthawk. These parts offer a crisp trigger action, excellent metal, and a top-notch finish. Safety is high and the result is an improved handgun, not a butchered handgun.

A part that doesn’t receive its share of attention is the hammer. A top-grade hammer included in the action kit will solve a lot of problems. It isn’t often noticed but it is common for a factory trigger to rub on the slide or frame during operation.

Let me share with you a few details on a pistol a friend took in on trade. The hammer followed when the slide was dropped. In other words, the hammer fell off its perch in the full cock notch and slammed into the firing pin when dropping the slide…without a finger on the trigger. The hammer hook was not polished. It had, instead, been ground down far too much. Don’t grind, polish! The hammer hook should be .018 to .020 inches high. Sear engagement is critical to function and safety. Craftsmen have been doing safe trigger jobs on 1911 handguns for one hundred years. Modern MIM parts and haphazard, untrained, ten-thumbed kitchen table gun butchers have forced me to recommend never doing a trigger job on the 1911. I no longer perform such work on my own guns. Buy trigger sets from top-of-the-line makers and you’ll count it money well-spent.

In the case of a butchered Remington 1911, I was able to easily drop in a Springfield factory set. I had fitted a quality aftermarket action to one of my Springfield 1911 handguns, so I retrieved the Springfield parts from the parts bin. They lined up and went in perfectly. The trigger is smooth, and while the break isn’t 3.5 pounds, it is consistent, reliable, and safe!

In a similar situation, I fitted a Wilson Combat AR-15 trigger in a Springfield Saint. The result was a superb trigger. Not too long after, a trigger failed in an inexpensive AR build. It actually came apart! The Springfield Saint trigger group went in, and while it isn’t Wilson Combat smooth, the result is a much better trigger. So, save the quality parts from an upgrade and trashcan broken and poor-quality parts.

Let’s look at 1911 triggers again and why they get so much attention.

I suppose a lot of folks think a good trigger will make them a great shot. Not true, but a good shot will shoot better with a smooth, crisp trigger. To obtain a lighter action, you must not smooth a factory steel trigger but add an aluminum trigger. The decrease in weight makes it much less likely the trigger will bounce the sear in recoil and fire the pistol when we do not wish it to fire. The trigger bow will require some polishing. The magazines sometimes rub on the trigger bow and the bow must be polished, and perhaps the magazine as well. This isn’t needed as often with better quality handguns.

While the GLOCK is easy enough to drop in a barrel, I have come across a few odd situations with the GLOCK. Most aftermarket sights are great and no trouble to fit. But a friend purchased a guide rod and ran into trouble. Advertised as a high-quality unit designed to tame recoil and keep the recoil spring straight, the unit was quickly beaten on the end. I have seen 1911 full-length guide rods do the same thing. Quite a few units get banged into the locking lugs and don’t look right and probably present a liability issue. I examined the guide rod my friend put in his GLOCK — it was precipitously beat up and had no place in a defense pistol. I don’t see what can be done to help these drop-in parts; the dimensions are the problem.

To recap, in the case of the 1911 handgun, drop-in parts are more likely to drop into a GI-type pistol than a high-grade production piece. Top end pistols, held to tight tolerances in the first place, will probably not be the most fertile ground for drop-in parts. But then, who needs to add parts to these types of pistols? We must keep drop-in parts in perspective, specify our whims, and consider before spending hard-earned money. As an example, the addition of a Bar-Sto barrel of the drop-in type to a GLOCK always results in increased accuracy.

My experience with drop-in parts has been positive overall. While they may not give the results of true match-grade parts, often they do. When a reputable supplier is chosen and care taken in handgun selection, the combination will result in increased performance at a modest price.