If you’re late to the micro-diameter hunting arrow party, here’s why you may want to switch now.

by Jace Bauserman

Not all arrows are equal. Some sport large diameters — 3D-goers call them “line cutters.” Others are built for those dipping their toes in the stick-and-string ocean. Some are carbon. Some are aluminum. Some are a blend of both. Spine sizes vary as do straightness ratings. I could go on. Bottom line: arrows are engineered for specific purposes.

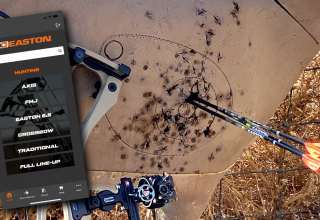

Once the minds at Easton Archery hatch a plan, nothing is left to chance. When this arrow kingpin decided to engineer a micro-diameter 4mm carbon shaft that would fly like a dart, hit like a freight train, and hold velocity on impact, bowhunters got excited. Rightly so, the 4mm Carbon Injexion carried a lot of hype. The good news, especially if you’ve yet to nock this killer on your string is: the hype has been more than lived up to.

The Build

My dozen Carbon Injexion shafts arrived in a spine size of 400 and tipped the scale at 8.9 grains-per-inch. Sleek and sexy, the shafts cut easily on my Cabelas arrow saw. After buzzing carbon, I used the included Chamfer Stone to prepare the insert end of each shaft for Easton’s HIT (Hidden Insert Technology) inserts. This step can’t be skipped. Place the stone on a heavy, flat object like a table, put the insert-end of the arrow over the nipple in the Chamfer Stone, and roll the shaft back and forth. Don’t worry, it’s normal for the arrow to shed some carbon during this process.

With the insert-ends prepared, use a small Allen wrench to push an alcohol pad into each shaft. Q-tips don’t fit. It’s important to remove excess carbon from inside the shaft for a proper insert-to-shaft bond. Your Injexion arrows will come with insert epoxy. Use a knife or scissors to open both pouches and let the epoxy mixture run together in a bowl. Use a toothpick to further mix the two substances. Use the same toothpick to apply some epoxy to your Deep Six thread G HIT steel inserts. Each insert sports a breather hole in the backend. Don’t cover this with epoxy, as it will run down and into the threads.

I like to start the inserts into the arrow with my hand, using a twisting motion to better distribute the epoxy to the shaft’s wall. I then use the included HIT Insert Tool to seat the insert up inside the shaft. Be sure to clean any excess epoxy from the tool between each insert setting.

Give the epoxy 24 hours to setup and then complete your arrow build. For this test, I wrapped each Injexion with 4-inch Bohning arrow wraps and attached a trio of 2-inch Bohning Blazer Vanes to each shaft via my Bitzenburger fletching jig. The arrows proved to be an easy build from start to finish.

The Tune

My finished arrow weight with a standard 100-grain field point was 415.8 grains. Arrow length was exactly 29 inches. All arrows were fired from a Prime Logic CT5 set at a draw length of 29 inches and a draw weight of 70.2 pounds. Each arrow was fletched with a three-degree right helical.

The 4mm Carbon Injexions tuned up like a dream. Speed was a solid 285 fps and a slight left horizontal tear was remedied (I’m a right-handed shooter) by moving my rest toward my riser. Kinetic energy for the Injexions out of my setup was 74.83 foot-pounds.

The Test

Even inside the small archery pro shop, I was amazed at how quiet the arrows seemed to be. The only deep thud detected was when the Injexions penetrated into the massive Block targets lining the back wall. One buried so deep it went into the plywood that had been placed behind the targets. We were able to pull the arrow out with an arrow puller, and there was no damage to the shaft.

With my Injexions dialed at 20 yards, it was time to hit the range. These arrows fly like bullets. Dialing in my 30- to 60-yard pins took little time, which made creating my dial-to-the-yard tape a breeze. Extreme downrange accuracy was also impressive. I shoot three-arrow groups at distances of 80, 90 and 100 yards offhand and through a Spot Hogg Hooter Shooter. Don’t shoot groups, even at extreme distance out of a Hooter Shooter. You will break arrows. At 90 yards, my three-arrow offhand group was sub six inches. The wind was blowing 7 to 9 mph from the north, which created a direct crosswind. I will take that type of accuracy all day. Due to the shaft’s micro-diameter, there is less surface area for the wind to press against. Just for kicks, I shot the shafts at distance in wind speeds of 18 mph, again from the north, to ensure the wall was taking the brunt of the gust. I was super impressed with their consistency. Consistency builds confidence.

Helping the arrows achieve jaw-dropping accuracy is the Focused Front-Of-Center design. Arrow F.O.C. is critical to long-range accuracy and is a primary focus of target shooters competing for big checks and podium placement. Typically, an arrow with a high F.O.C. rating will fly with good stability but will lose trajectory and nose-dive at an increased rate. An arrow with a low F.O.C. tends to hold its trajectory, but often provides spotty downrange accuracy. Focused Front-Of-Center means a shaft that doesn’t rapidly loose trajectory and still hits with accuracy. The F.O.C. of my finished 4mm’s was 11.26 percent. Easton recommends an F.O.C. between 10 and 15 percent. Again, this F.O.C. was achieved with pre-installed Deep Six Nocks and Deep Six G HIT steel inserts.

I mentioned how quiet the shafts were inside a small, narrow pro shop. They were even quieter outside. Using a video camera with a high-definition microphone, I shot the 4mm Injexion shafts along with a pair of other shafts sporting larger diameters. The noise meter doesn’t lie. The Injexion shafts proved way quieter.

As for penetration, I was truly blown away. I shot three arrows from 40 yards into a never-been-shot-before Block target. The 4mm Injexion’s penetrated 2.34 inches deeper with standard 100-grain field points and 2.46 inches deeper with 1.5-inch cut SEVR mechanicals. Of course, the Deep Six thread G HIT steel inserts help. The stainless steel is 65 percent stronger than conventional aluminum, and the direct point-to-shaft bond is also a hat-tipper. The main reason for the penetration boost, however, is the micro-diameter nature of the arrow. Not only is velocity at impact increased, but because the shaft sports a small outside diameter, it can track behind a broadhead. If you’re looking for maximum penetration and a shaft that is tough as nails, give the 4mms a go. I was seriously impressed with the shafts, and you will be too.

Quick Facts

If you plan to purchase 4mm Carbon Injexion shafts, you can choose from spine sizes of 480, 400, 330 and 280. In addition, you will want to make sure and purchase Deep Six field points and broadheads. Standard 8/32-thread points will not work. The purpose behind the Deep Six system is for points and broadheads to taper down to better match the diameter of the shaft. This taper reduces friction and drag. If you want to stay with your standard 8/32-thread points and broadheads, Easton does offer a 4mm Half-Out Titanium Insert. If you choose to go this route, you will not use the HIT inserts that come with the arrows.

For more information, visit www.eastonarchery.com.