A three-piece AR trigger that feels right, installs easily, and won’t wreck your budget? Yes! A new company called Axcess Triggers has just launched their first offerings for the AR platform. Here’s the scoop…

by Rob Reaser

Historically, AR triggers have taken two paths. Path #1 is the MILSPEC design — Stoner’s original configuration that has worked well for decades. Path #2 is represented by aftermarket triggers — assorted designs that are major leaps ahead of the MILSPEC variety in terms of precision and overall performance. And just as the performance differential between MILSPEC and aftermarket AR triggers is huge, so, too, is the price.

A crisp, solid-performing aftermarket trigger, whether in the traditional three-piece design or the popular drop-in cassette-type trigger, will run in the $200-$350 range on average…and they are definitely worth the money if you are looking to increase your accuracy potential.

As for the standard MILSPEC trigger that graces most off-the-rack, unmodified ARs…well…their $30-something retail price should tell you all you need to know.

Let’s face it. MILSPEC AR triggers — the ones found in most civilian and LE rifles today — haven’t changed in forever. Is there a better way to get a higher-quality trigger in an AR without taking the massive leap to a premium, machined aftermarket trigger and to do so without jacking up manufacturing costs in a marketplace where margins are already razor-thin?

That was a question posed by several firearms manufacturers to one of the oldest and most respected names in the aftermarket trigger industry, and that question was answered by a new company called Axcess Triggers.

“Huh?” you say.

Who is Axcess Triggers?

Axcess Triggers is a company established by aftermarket trigger leader Timney Triggers out of Phoenix, Arizona. The two companies are in the same family and are equally committed to a “100% Made in America” pledge, but they are two distinct and separate entities.

Timney Triggers has been delivering premium trigger systems to hunters, competition shooters, and recreational firearm enthusiasts since 1946. The new Axcess Triggers has a somewhat different mandate as another point of distinction. According to the company, “Axcess started out as an OEM request to improve the feel and repeatability of the standard three-piece AR trigger — a proven design we refined for accuracy — and soon evolved into something we knew every gun builder and armorer should have access to. So, we created a brand and named it after exactly what we’re doing: providing access to accuracy at a price that doesn’t break the bank.”

In sum, Axcess Triggers has produced a solution for OEMs seeking a basic, cost-effective three-piece AR trigger that leverages new manufacturing technology and offers enhanced performance without negatively impacting their rifles’ consumer price point.

And now, Axcess is also selling their new AR triggers direct to the public. This is great news for AR owners who have legacy MILSPEC triggers in their rifles and are seeking an upgrade but who aren’t ready to spend big money on a premium trigger system.

Axcess AR Triggers Close-Up

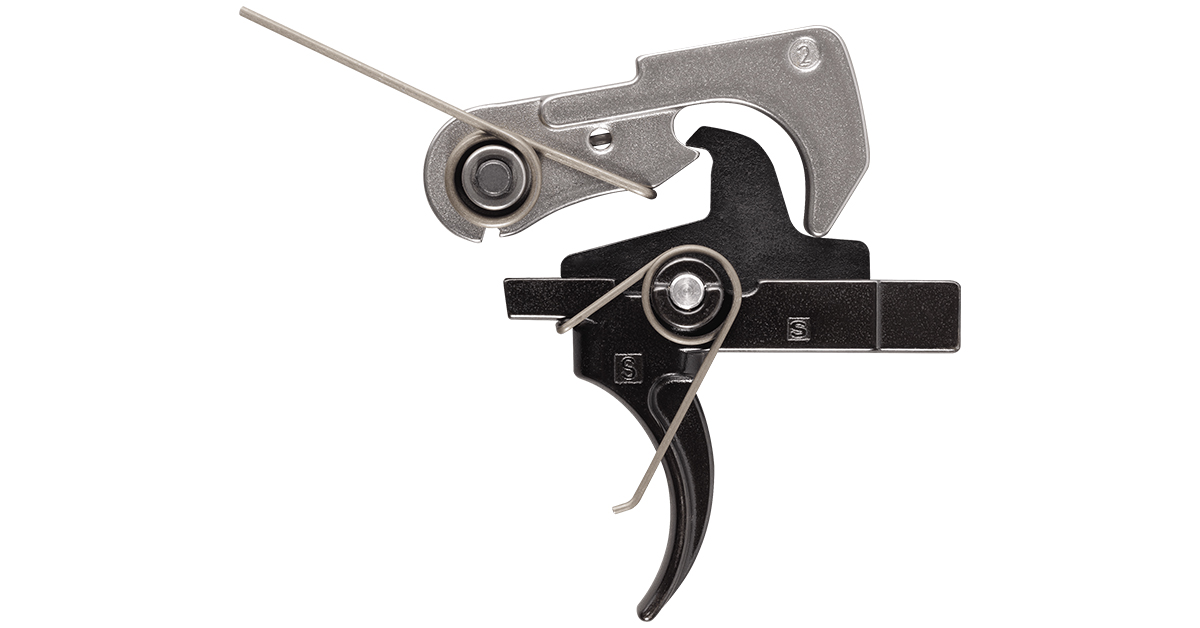

Axcess triggers for the AR platform follow the general pattern of the original MILSPEC design. These are three-piece triggers comprised of the trigger, disconnector, and hammer. Each trigger includes the pre-installed hammer and trigger springs, the disconnector spring, and a retaining/guide pin securing the disconnector to the trigger. For the debut, Axcess is offering these triggers in three variations:

Black Oxide (MSRP: $65.99)

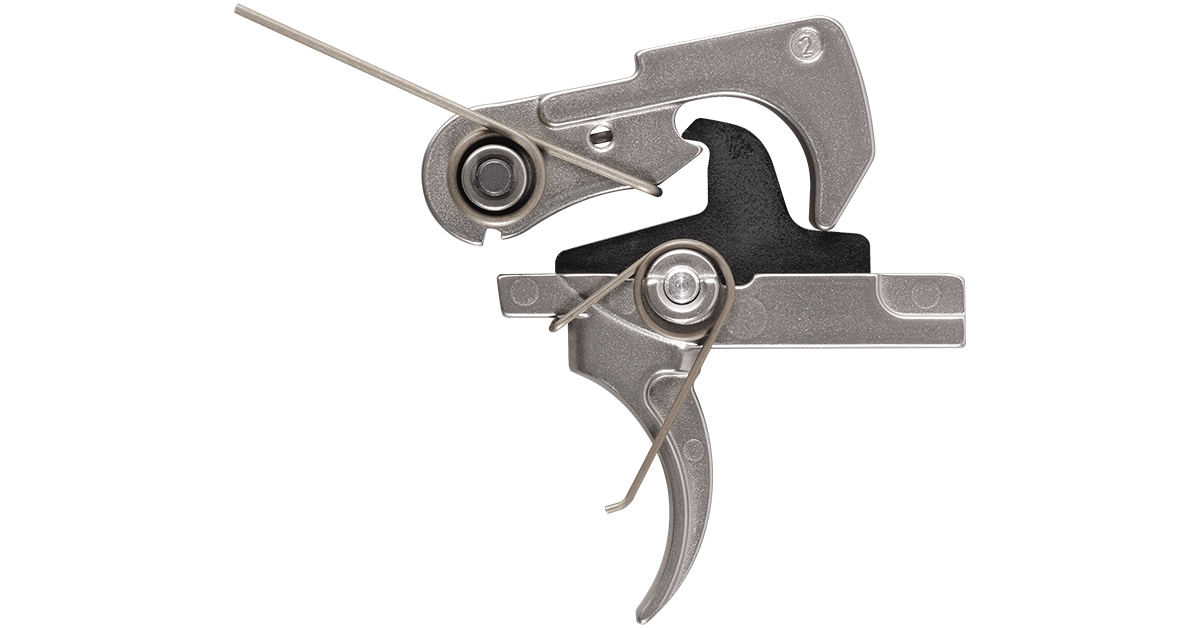

Oil Slick PVD (MSRP: $87.99)

NP3 Teflon-Nickel (MSRP: $87.99)

So, the natural question is, what separates the Axcess triggers from the traditional MILSPEC triggers?

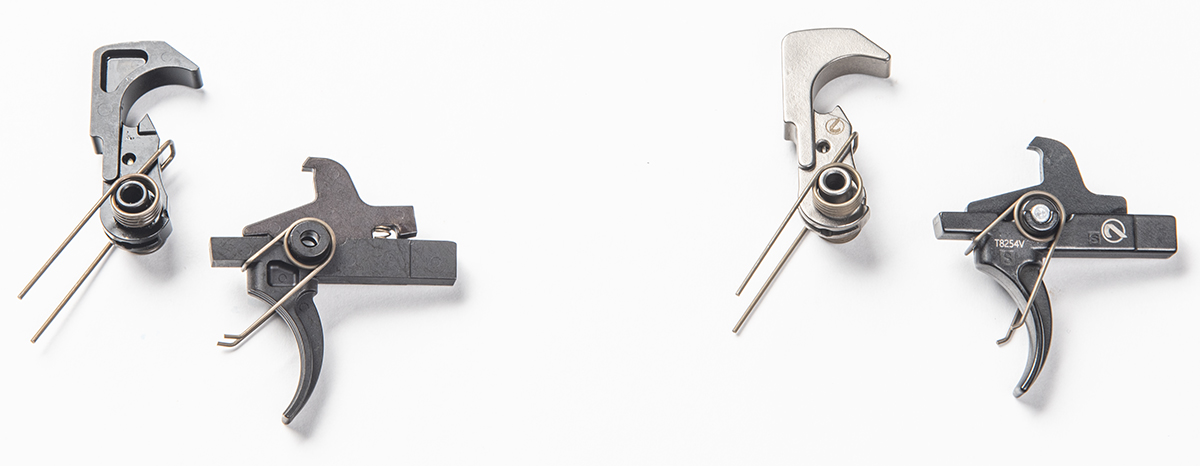

From the side-by-side view, not much. Close examination reveals a slight profile difference in the hammer hook edge. The Axcess (right) hook has a more rounded edge than the MILSPEC (left), making for smoother engagement when it pushes against the disconnector. Only minor, non-functional differences are found between the two triggers.

The biggest difference is in the disconnector, where we find a few changes in dimensions and engagement surface geometry. Axcess explained to us that this is a proprietary disconnector design that their engineers developed. Since the disconnector’s function is to capture the hammer as it is overridden by the bolt carrier during cycling and then to transfer the hammer to the trigger sear, it is a good bet that this design also contributes to the unit’s smoother trigger reset performance.

“Smooth” is the operative word when discussing Axcess triggers. This covers disconnector engagement, trigger/hammer sear travel, and overall surface quality.

Part of the modern manufacturing techniques Axcess brings to the proven three-piece trigger design is a state-of-the-art tumbling process. The components are tumbled in a special media to ensure a smoother surface for the cast parts. In this way, Axcess triggers can edge toward that machined-and-polished premium trigger feel yet keep costs down by casting the hammer and trigger.

Hammer and trigger surface treatment is also a big contributor to the upgraded performance. The additional $22 for the PVD- and NP3-coated models delivers an inherent surface lubricity that reduces friction while also boosting wear- and corrosion-resistance.

Access Trigger Evaluation

Before running the NP3-coated Axcess trigger in an AR, I was curious to see what the difference might be in the trigger pull weight between it and a MILSPEC trigger. Starting with the MILSPEC trigger, the Lyman scale revealed an average (10 pulls) weight of 3 lbs., 11 oz. The M16A2 calls for a trigger pull weight between 5.5 and 8.5 lbs., so this particular “MILSPEC” trigger tested was anything but MILSPEC in this regard, being too light. Also, I noted during testing that the pull weight varied significantly from pull to pull, with some pulls in the low 3s and others in the high 6s.

Swapping for the Axcess trigger, things were much more consistent, with pulls running between the high 3s and mid 5s. The ten-pull average clocked in at 4 lbs., 8.7 oz. Axcess specs these single-stage triggers at 5 lbs., so these results were pretty much spot-on. And again, the consistency of the pulls was noteworthy because repeatable performance is what you want for accurate shooting.

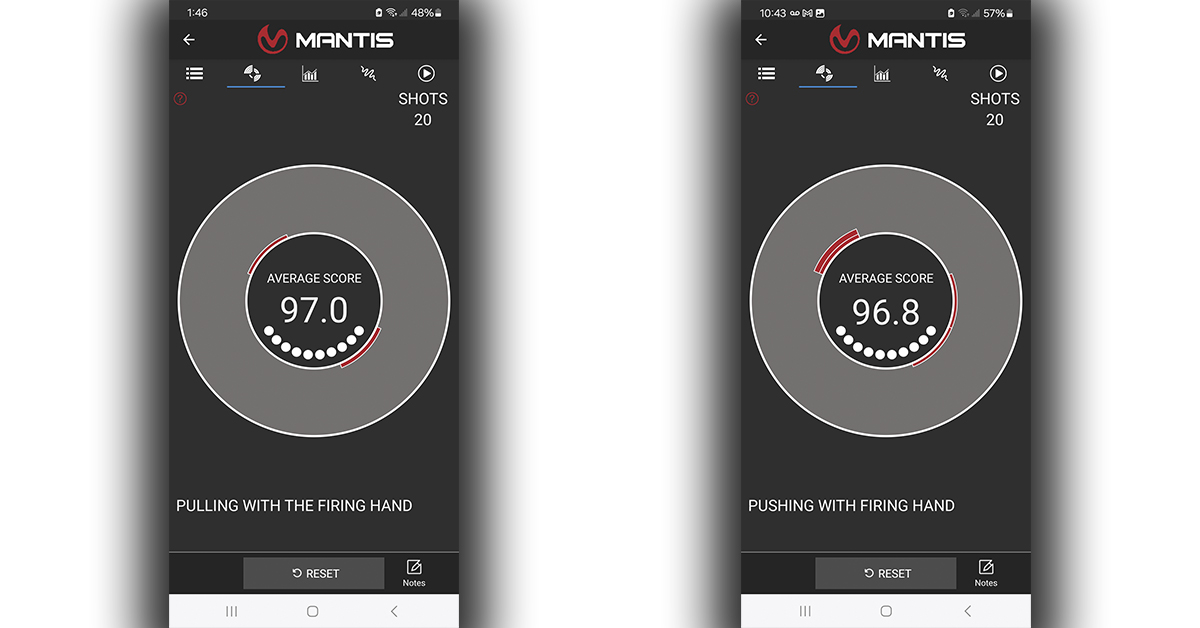

For the next portion of the test, I wanted to put some “meat on the bone” instead of delivering the usual subjective observations like “smooth and crisp.” To do this, I loaded up the rifle with the Mantis Blackbeard dry-fire training system to get some real, objective data. This is one of the great things about the Mantis Blackbeard — it breaks down your shot performance and shows in exquisite detail exactly what is happening throughout the shot cycle. I figured that by using it with both the MILSPEC and Axcess triggers I should be able to identify any performance differences between the two.

There was a difference between the two triggers, but it was marginal. Shooting in the unsupported prone position, I Iogged a 96.8 out of 100 with the MILSPEC trigger (20 rounds). After a trigger swap, it was back to the shooting mat for another 20-round set. The score bumped up a tad to 97/100 with the Axcess trigger.

Was this an improvement? I would have to say “yes” to some degree. I’ve found that once your trigger control hits the mid-90s with the Blackbeard system, any gains or losses due to equipment changes tend to be rather small. Remember…training trumps equipment.

An Enhanced Upgrade – Easy All-Around

Whether you are an AR-15 owner who is just starting to engage the platform for personal defense, competition, or hunting and want to kick your rifle up a notch, or you serve as armorer for your department or agency and want “something better” when it’s time to replace parts, the new Axcess three-piece enhanced trigger is the smart option to upgrade from your MILSPEC trigger without dropping serious coin on a premium, machined aftermarket trigger. The swap is a straightforward operation and Axcess includes new hammer and trigger pins with each kit.

A good price point AR trigger with components made using the latest technology…that’s a tough bargain to beat.