Brass takes a serious beating in the chamber. Part of the reloading process is getting it back into shape. In this edition of our reloading series, we’ll cover the tools and techniques to do just that.

by Lou Patrick

In the previous edition of our extensive reloading series, we presented a deep dive into the component that brings together all the other components that make up a cartridge — the bass case — and began the journey of preparing cartridge cases for reloading. This time, we take a look at the hows, whys, and wherefores of cartridge case resizing.

The reloading process begins with resizing the once-fired cartridge case. To be more precise, it begins with resizing and removing the old primer, as these two steps are usually accomplished simultaneously with the dual function of either a full length or a neck resizing die.

As mentioned earlier in this series, the reloading process allows for some flexibility as to when or how some of the reloading steps are accomplished. The reloading process, as presented here, is simply my approach to reloading and is not intended to be presented as “The Way” of doing things. It also requires the reloader to make some decisions. Perhaps the first decision to be made concerns resizing. Do you perform a full-length resizing of the cartridge case or only resize the case neck by using a neck resizing die? Whichever you choose, the operation as performed during the reloading process is practically identical. Keeping within the parameters as stated earlier in this reloading series (reloading for a bolt-action rifle and the reloaded ammunition will be used in the same rifle that produced the once-fired brass), my advice is to neck-resize the brass because neck resizing prolongs the longevity of your cartridge cases. Remember, it is the expansive cartridge case that makes reloading possible. The case is also the most expensive reloading component. The longer that your cases last, the more money you will save.

The reloading block is essential for helping you to keep track of your work as you reload. Begin by placing all the cases on one side of the block.

I prefer to begin reloading by removing the primer with a universal decapping die. This die does not resize the case. It will only remove the primer. Yes, this does add an additional step to the reloading process; however, primer removal with this die is fast and easy, so we aren’t adding much time to the reloading process.

Install the decapping die into the reloading press and adjust it according to the manufacturer’s instructions. Here, we are using Hornady’s single-stage press and decapping die. Insert the cartridge case into the shell holder.

Lower the press handle. The cartridge case will rise into the decapping die and the decapping pin will push out the primer, allowing the fired primer to fall downward into the primer catcher.

Raise the press handle and remove the case. Repeat this process until all the primers have been removed. Once the primer is removed from the cartridge case, return it to the reloading block, placing it in the forward side of the block.

My preference for cleaning cases is to use a rotary tumbler. This method of case cleaning uses small stainless-steel pins and a cleaning solution mixed with water. Here, we are using Hornady’s programmable Rotary Case Tumbler.

Unlike traditional walnut or corn cob media that is used with vibratory tumblers, the stainless-steel pins will never wear out. Another advantage of this method is that all the dirt is discarded after each cleaning session. Also, if you or someone in your household suffers from dust allergies, this is probably the best method for you to use. More information on rotary or “wet tumbling” can be found here.

Once the cases are clean, rinse them thoroughly in clean warm water and dry them. You can use something like the Hornady Digital Cases and Parts Dryer shown here or let them stand overnight as shown.

Removing the primer as a separate operation from resizing and then cleaning the cases has two advantages, in my opinion. First, it’s my preference to only run clean cases through my resizing die. This is also discussed in Hornady Podcast #37 Let’s Talk Reloading. Second, with the primer removed, the cleaning media can now clean the primer pocket. While I have never heard of any problems attributed to dirty primer pockets, good reloading practice dictates that cleanliness is a key element in the quality of workmanship, and good workmanship leads to accuracy.

It’s always important to look at the cartridge case headstamp when identifying the case and not to entirely rely on the ammunition box. Some ammunition boxes may appear to be “civilian” but the cartridges they contain may be using military brass. Additional information concerning ammunition that is using military brass can be found here.

After cleaning, the next step is resizing the case. If you are working with military brass as pictured above, though, things become a little different. The primers on military ammunition are crimped in place. This crimp must be removed prior to installing a new primer. The primer crimp serves to hold the primer more securely. This is an obvious advantage for ammunition intended for use in combat. This crimp also makes primer removal a little more difficult compared to civilian ammunition. Combine “crimped primer” removal with the added force required in resizing the cartridge case and it is another reason why I prefer to remove all primers prior to resizing.

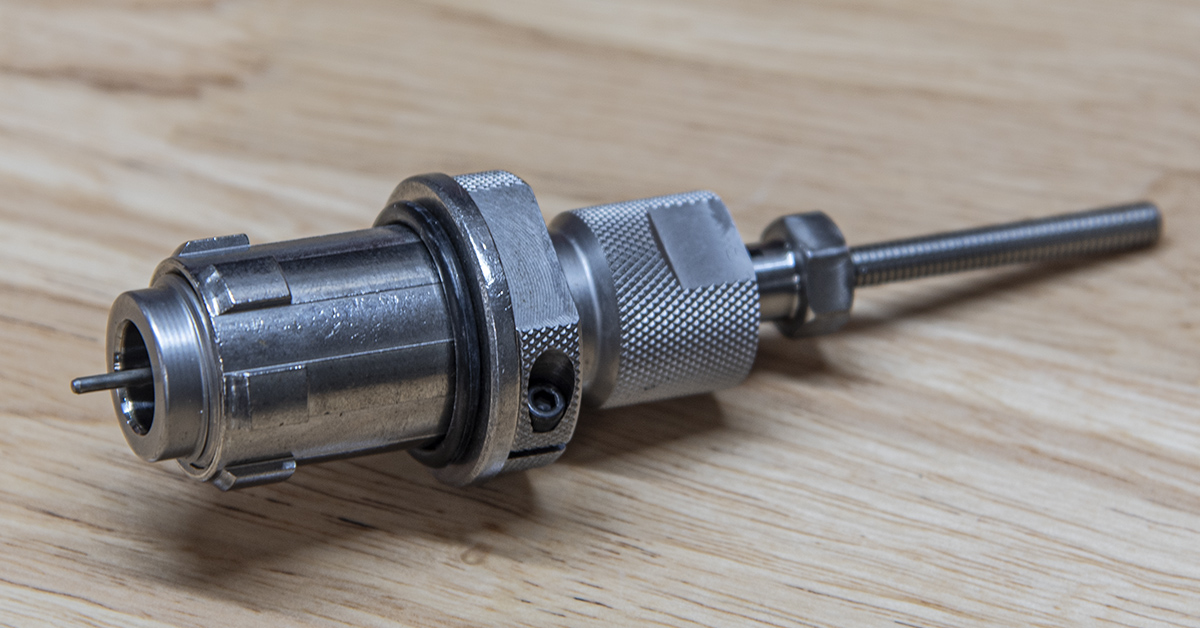

When working with military brass, following cleaning, my next step is to remove the crimp. The easiest way that I have found to do this is by using a primer pocket swaging tool such as the Hornady Single-Stage Primer Pocket Swage Tool pictured here. The swaging tool is available for either large or small primer pockets.

Install the swage tool in the reloading press and adjust according to the manufacturer’s instructions. Removal of the primer crimp is a quick, easy, one-time operation. Once the crimp is removed, you will not need to perform this operation again for the life of the brass.

The full-length resizing die will simultaneously remove the fired primer and resize the full length of the case. This includes moving the shoulder back. This is important to keep in mind as we are working with .308 Winchester cartridge cases. These cases are rimless and have a shoulder. For a cartridge of this case design, it is the shoulder that controls the position of the cartridge in the chamber. More information concerning this is contained in Part 6 of this series.

Install this die into your reloading press and follow the manufacturer’s instructions concerning its adjustment and you will be fine. What you need to be aware of at this time is that the further you turn this die down into your reloading press, the further back the shoulder of the cartridge case will be moved during resizing. Moving the shoulder too far back will result in the case moving further forward in the rifle’s chamber than designed. This will ultimately result in excessive headspace.

One of the goals for the reloader is to extend brass life. With this in mind, remember that we are reloading for a bolt-action rifle that fired this brass when it was new. In this instance, full-length resizing is not needed and is undesirable, in my opinion. Yes, full-length resizing will work and work fine. I also doubt that you will see any difference in accuracy as compared to other resizing methods. The downside to full-length resizing is simply that it reduces the life of the brass. This is because the cartridge case expands to seal the chamber when fired. Once chamber pressure drops, the case will somewhat return to its original size, allowing for extraction (although it is now somewhat larger than its original size). Full-length resizing will more closely return it to its original size. When fired a second time, it will then have to fully expand once again, then full-length resized again. This constant expansion/resizing across its entire length will cause the brass to become hard and brittle.

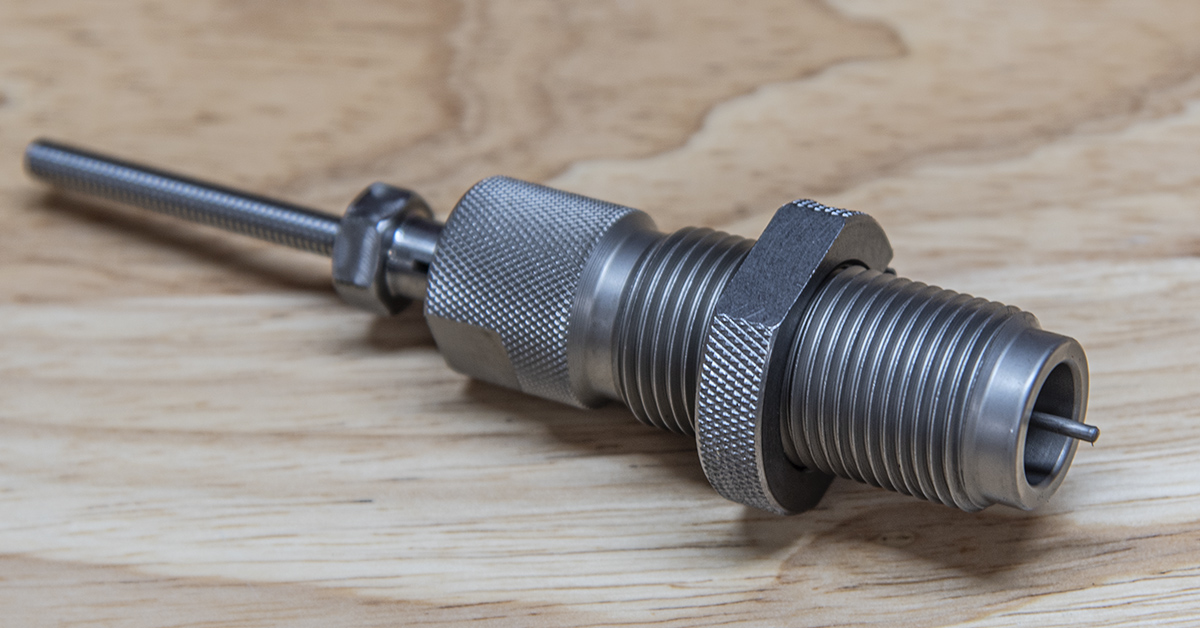

The neck resizing die will simultaneously remove the fired primer while only resizing the neck of the case. When using this die, all that you are doing is resizing (compressing) the neck of the case in order to properly accept or hold the new bullet. Neck resizing greatly reduces the working stress (expansion/contraction) placed on the brass. The result is a much longer usable life span of the cartridge case. Neck resizing has also been touted as enhancing accuracy; however, I have not experienced an increase in accuracy that I can directly attribute to neck resizing. New brass or full-length resized brass seems to shoot just as accurate as neck-resized brass in my experience.

While neck resizing does provide the desirable benefit of extending the life of your cartridge cases, you may be wondering why even have a full-length resizing die? The short answer is, eventually you are going to need it. Remember, once the expansive cartridge case is fired, it will expand to seal off the chamber. Once chamber pressure drops, it will somewhat return to its original size. The key word here is “somewhat.” Eventually, neck-resized brass will grow to a point that it will be difficult to chamber the round. The first indicator of this is when you notice that the bolt handle has a little more resistance than normal when closing. As you gain experience, you’ll learn when your cases will need to be full-length resized.

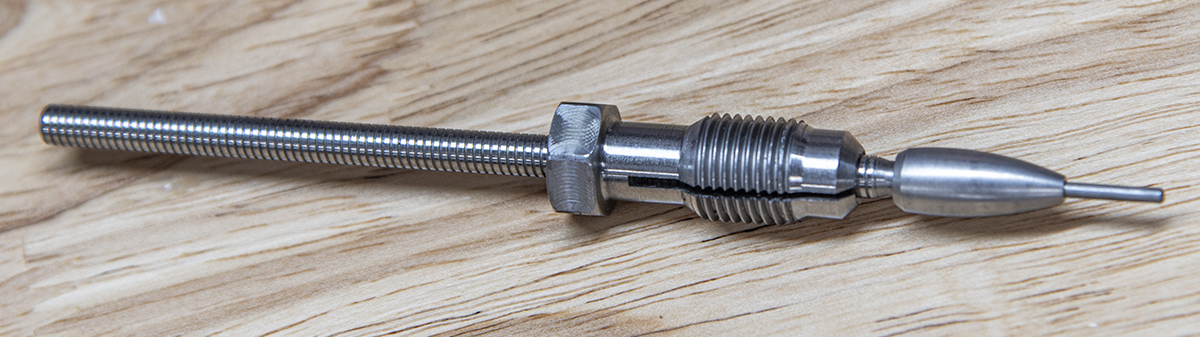

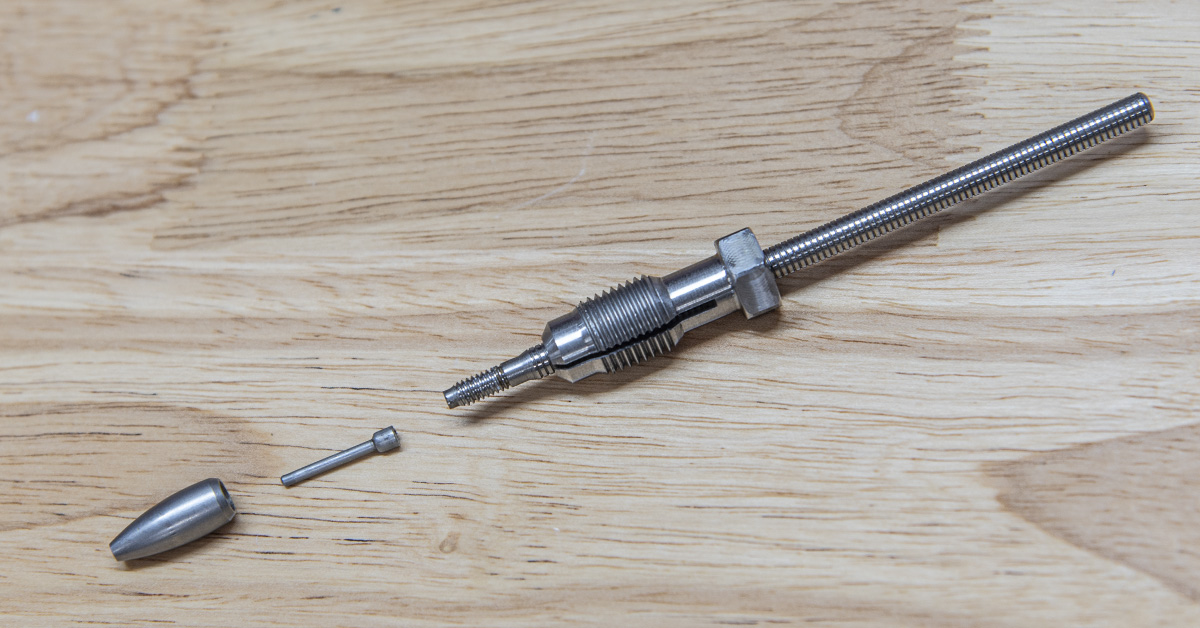

Prior to installing and adjusting the neck and full-length resizing dies, I recommend removing the decapping pin from each die. The decapping function is not needed as this step has already been performed with the universal decapping die. Yes, the pins can be left in place, yet it is possible to bend or break a decapping pin during use.

On Hornady dies featuring the Zip Spindle system (shown here), unscrew the spindle from the die body.

The decapping pin is held in place by the expander, which is located directly above the pin.

Unscrew the expander and remove the decapping pin. Reinstall the expander onto the spindle and reinstall the spindle assembly into the die body.

Whether we are speaking of full-length resizing or neck resizing, the operation of each die is similar. As the press handle is lowered, the case is raised into the resizing die. The mouth of the once-fired case will easily pass over the expander button. As the case continues into the die body, you will begin to feel some resistance on the press handle as the brass is being resized. You will feel more resistance on the press handle when full-length resizing as compared to neck resizing because you are resizing more material. Once the press handle is all the way down, the case is now completely in the die. How much of the case gets resized (full-length vs. neck) is a function of the die body being used. The expander button is now located close to the case web. If the decapping pin were being used, it is easy to see how it would pass through the flash hole, forcing the primer out of the case.

It is undesirable to have the die adjusted to where the expander button can contact the case web. In my opinion, this is another advantage of decapping with a dedicated decapping die and removing the decapping pin from resizing dies. This method allows the expander stem to be adjusted to allow more clearance between the expander button and the case web, ensuring that it will never contact the web.

Once the press handle has reached its full downward position, it is then raised, bringing the cartridge case downward and out of the resizing die. At this time, the case has either been full-length or neck resized. In either instance, the case mouth and neck are currently too small to accept the new bullet. As the case continues its downward motion, the expander button will pass through the case neck and mouth, expanding it to the proper dimension needed to accept the new bullet. You will feel some slight resistance on the press handle as this occurs.

When full-length resizing, the case body must be lubricated. I prefer to do this using a lube pad, although Hornady’s One-Shot aerosol case lube is just as effective and faster to apply.

Place a small quantity of case lube on the pad and spread it evenly across the surface of the pad with your fingertips.

Do not lubricate the shoulder, as this will cause dents to appear in the shoulder.

From bottom to top, roll the cases with slight downward pressure across the lube pad. When full-length resizing, I will lube 5 cases at a time, place them in the loading block, and then repeat the process until all the cases are lubricated.

For neck resizing, only the case necks need to be lubricated. My preference is to use resizing wax for this operation. Using your fingers, simply place a light coat of resizing wax around the entire circumference of the case neck.

Cases must be properly lubricated otherwise they will likely become stuck in the die, requiring the use of a stuck case removal tool. I find it best to have a case removal tool on hand and simply hope that you never need to use it. If you reload enough, eventually you may need it.

Install the appropriate resizing die into the press and adjust it according to the manufacturer’s instructions. Place the lubricated case in the shell holder and lower the press handle. The case will go into the resizing die. Once the press ram has reached the top of its stroke, raise the press handle, removing the case from the die.

Wipe off the excess case lube from each piece of brass following resizing. I do this immediately after removing it from the press and before placing it back into the loading block. Just as your rifle’s chamber should be clean and dry (meaning absence of lubricant), the cartridges going into it should also be clean and dry.

Following resizing, measure each piece of brass. If you measured them before resizing, you’ll likely find that they are now somewhat longer and that they are not of identical length. Brass that has been full-length resized tends to grow a little compared to brass that has been neck sized. The Hornady reloading manual states that the maximum case length for the .308 Winchester cartridge is 2.015 inches. Much of our brass is currently at that length. The next operation will be trimming the brass to the desired length, which we will cover next in Part 8 of this series.