Our blade expert explains how to gauge a quality knife and ensure you get your money’s worth the next time you trade cash for steel

by Dexter Ewing; photos by Marty Stanfield, Marty Stanfield Photography

You work hard for a living not only to have the means to afford the daily necessities but also for the things that make life more bearable and enjoyable. We need to make sure that what we buy delivers the best value for the money. Knives are no different.

While manufacturers are generally pretty good at doing quality control, the occasional bum knife may slip by. Here, we want to take a close look at knives and what to look for in terms of quality. There are scads of knife models on the market, and from the countertop view, most look pretty darn good. Looks, though, do not equate to reliable performance. Take the following advice into consideration when you’re shopping for a knife and you stand a better chance of shifting the price-to-performance ratio in your favor.

For All Knives

Whether you are buying a fixed blade or a folding knife, a close inspection is in order. This is akin to “kicking the tires” when shopping for an automobile.

First, do all the knife parts fit together well? Examine the overall knife and the parts that make up the handle. You’re looking for uneven fit and finish. Does the handle material have good fit to the blade tang or handle liners? Any protruding areas? Any gaps in the fit of the parts? If the handle has bolsters, how do the bolsters fit to the tang or handle liners? How does the handle material fit up to the bolster? Any gaps?

Remember, when inspecting the fit and finish of the handle, you “look” as much with your fingers as you do with your eyes. Run a finger over the parts of the handle and along the radius. A properly finished knife handle should feel smooth with no detectable unevenness or varying of texture. Everything should be as uniform in feel as it is in appearance.

Look at the surface finish of the handle in good light. Is it even? Are there any visual variances that you can detect? How does the handle feel in your hand? At this point, don’t be concerned with the visuals. Close your eyes and pay attention to the feel of the knife in your hand. Any harsh edges? Anything sticking up that might produce a hot spot during use? Is the contouring of the edges comfortable? Does your hand feel secure on the grip? Is it too thick/bulky for your hand? Is it too thin? Either can affect knife performance because the handle is the user interface.

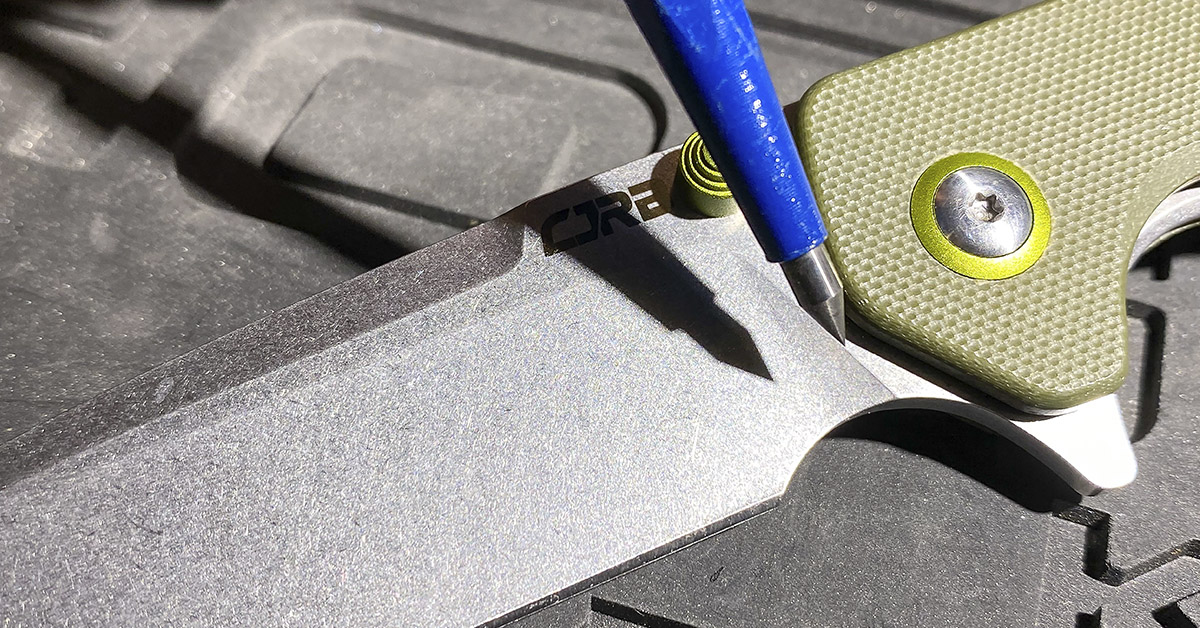

Next, we look at the blade by itself. Examine the plunges (the points where the grinds begin, right at the blade tang. Are the plunges symmetrical? Most production knives are CNC-ground, so the entire process is computer controlled and generally your plunges will be symmetrical, although there are times where you will see they might be off just a titch. If so, it’s not a big deal. If they are off a lot, then that can influence cutting performance because the blade isn’t ground symmetrically.

Take a good look at just the cutting-edge grind. This is the part of the blade where the rubber meets the road, so to speak. Here is where manufactures sharpen the blade to bring it to life. Again, hold the blade in good lighting. Rotate the blade back and forth to reflect the light as you visually inspect the cutting edge. A properly ground edge will be uniform in appearance. If you detect some irregularities, then that means the blade wasn’t properly sharpened. Sharpening is usually done by hand in a quality knife. It is not a step that can be replicated by machine. In short, there is no substitute for human touch.

Now consider the actual finish of the blade. Most blades have a machine satin finish where the scratch marks run perpendicular to the cutting edge of the blade. Look at both sides of the blade in good lighting. Hold the blade at varying angles in the light. This will bring out any inconsistencies in the satin finishing process, if there are any, but this step is fairly difficult to screw up. You’re also looking for tooling marks that might be left behind on the blade. These usually show up as coarse grind lines that are made during the blade grinding process, where the blade’s primary bevels are machined in. When the blade is finished, these tooling marks are taken out as a part of that process but if the blade isn’t carefully finished or the process is rushed, then the tooling marks maybe visible. This usually indicates sloppy finish work. Tooling marks may be more evident in blades that are bead-blasted or even black coated.

For Folding Knives Only

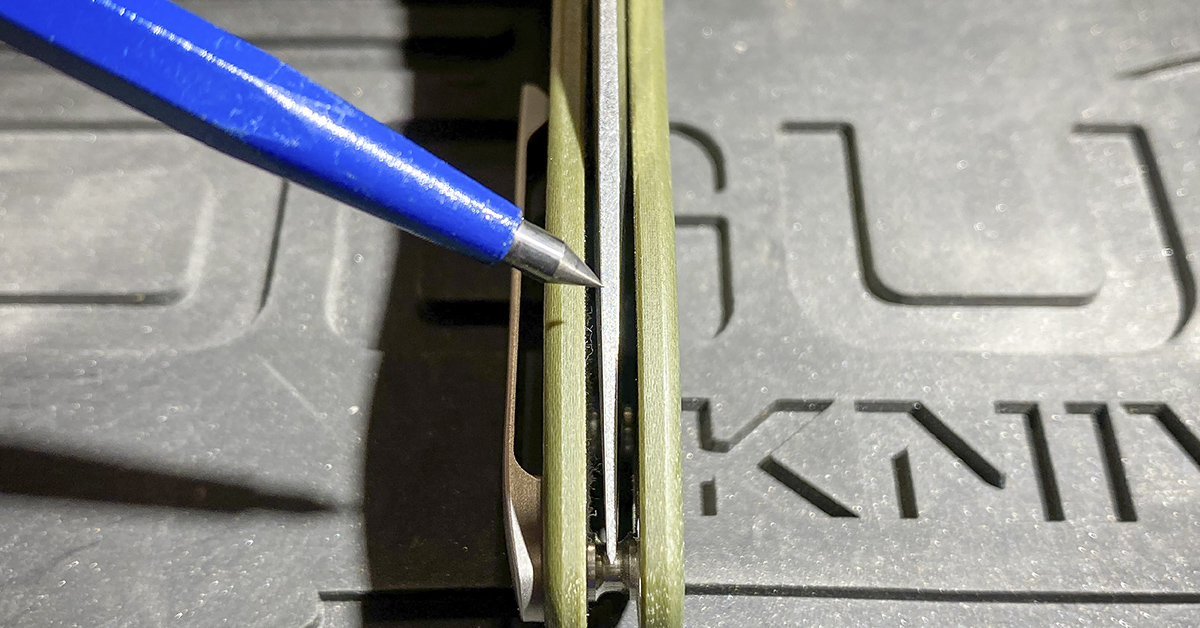

Folding knives have a mechanical component to them because of how the blade folds into the handle when the knife is not in use. With the blade (or blades, if this is a multi-blade slipjoint pocketknife), you will want to assess for blade straightness. Are the blades centered between the handle liners? Open the blade(s). Does the action feel smooth? Once open, and if this is a lockblade, does the lockup feel secure with little to no lateral or vertical blade play?

The lockbar (if a liner lock or frame lock) should hit the blade tang on the lower third of the tang—the part closest to the lockbar. Naturally, the lock will break in and therefore might travel over a smidge toward the center of the tang, and that’s just to be expected. You don’t want it engaging too far over when brand new.

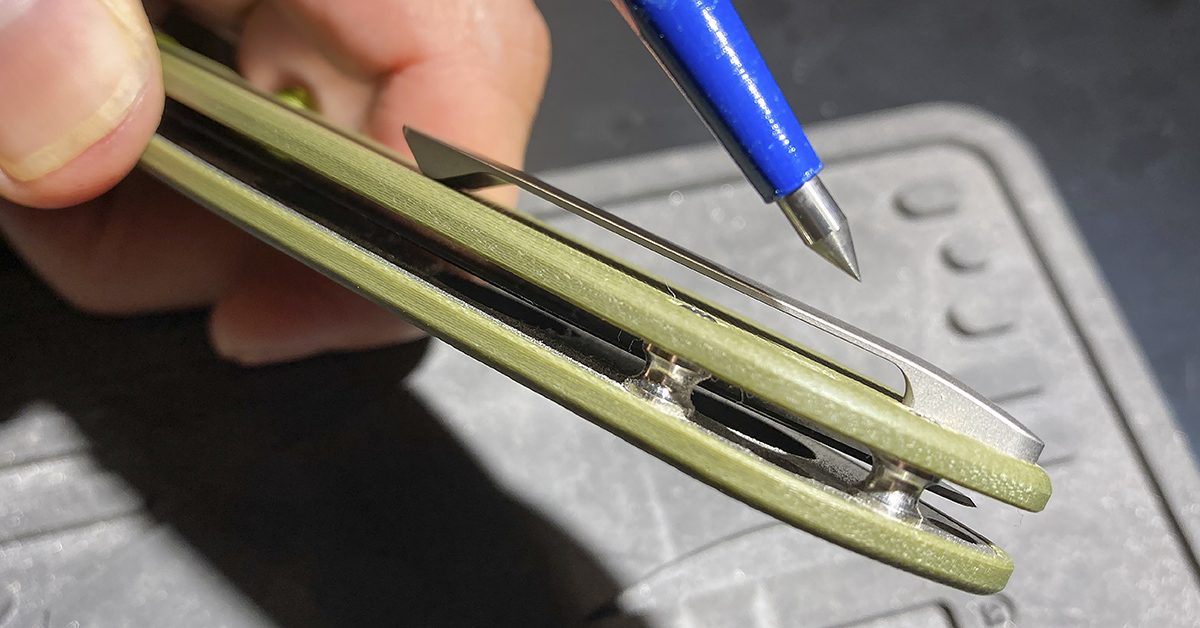

Carefully grab the blade with one hand and then, with the other, make your assessment. Some lateral play can be taken out by tightening the pivot screw (if equipped with such).

Vertical blade play of any amount, when open, is unacceptable. When in doubt, return the knife and ask for a new one that has no vertical play.

Another thing to watch for is if the blade is centered within the handle in the closed position. The blade should sit dead center equidistant to the handle halves on either side. If it’s sitting off-center just a smidge, then that is acceptable, but anything more that indicates the pivot maybe too loose. Tightening up on the pivot screw a bit will help to center the blade and might be what it takes to correct this.

Most modern single-blade lockblade folding knives will have a pocket clip fastened to the handle to aid in carry. The clip will be fastened to the handle by one larger screw or two or three smaller screws. They are usually of the Torx head variety and require the appropriately sized driver. Check to see that the clip is securely fastened to the handle with no wiggle at all. If there is wiggle, locate the appropriate-sized driver and tighten it up. Most small clip screws are T6 Torx.

For Fixed Blades Only

All fixed blades will come with a sheath of some type. Molded plastic, Kydex, or leather are common sheath materials. You want to check the sheath for fit and finish the same way you check the handle—by both look and feel. Any rough edges? Any uneven areas?

Leather sheaths have a combination riveted and sewn construction. Check to ensure the stitching is even and done neatly and the rivets are fully set. Inspect the belt loop, make sure it’s sewn (or riveted) on securely so the sheath won’t fall off while you are wearing it.

With fixed blades, it is important to remember that the knife and sheath equal the overall package. Sometimes, manufacturers may cut corners on the sheaths in order to meet the targeted MSRP for the knife. This often means not finishing the sheath to a higher standard or using a molded thermoplastic sheath instead of Kydex or even leather. While a good-looking sheath is desirable, keep in mind the main function of it is to hold your knife securely on the belt. If it does that, then there is some give and take with appearance.

If you follow these steps when selecting your next knife, you will be more satisfied with it. If you can make the purchase at a store, in person, you can carefully inspect the knife. Should you purchase online, be sure to carefully examine your purchase immediately upon receipt and, if you are not happy, contact the retailer ASAP to arrange a return for an exchange or get your money back.