Simple tweaks, good parts, and a bit of load experimentation can set your pistol to run like a champ

by Bob Campbell

Students of the pistol realize that handguns are devices of irreducible complexity. This means that if one small part fails the handgun will not function. An important part of the handgun that affects function is the recoil spring. This component also influences felt recoil in ways that are not always understood. Let me caution you — if your handgun functions properly, be certain you know what you are about before modifying the handgun. For competition use and range use, go ahead and jump in; just be certain the learning curve is at its apex before considering modifying a duty gun. That said, you may be able to increase speed and accuracy with a properly set-up spring set.

A quality handgun such as a Glock 9mm or Springfield .45 is a well-designed and executed machine. Every part of a self-loading pistol is replaceable, including the slide, frame, and barrel. But for the most part, they will outlast the shooter. Renewable parts include the magazine and recoil springs. They should be checked for wear from time to time and there is a set schedule for spring replacement. A spring doesn’t last forever. A 1911 .45 Government Model recoil spring should be replaced every 5,000 rounds, 3,500 rounds in a Commander-type .45. A 9mm Glock will go several thousand rounds more than a 1911. A CZ 75 9mm recoil spring should be replaced every 7,500 rounds. Striker-fired pistols should have the striker spring replaced along with the recoil spring. Some 1911 handguns may need the hammer spring replaced as well. A modest practice schedule of 200 rounds a month adds up quickly.

It is difficult to measure a recoil spring’s weight. The spring loses free length as it wears. If you have a replacement spring on hand and the spring in the pistol is .05 inches shorter than the replacement, then the spring is due for replacement. The spring is compressed during firing and compresses many times. Replacing the factory spring on a regular schedule will keep your handgun functioning for many years. A spring with a lighter rating is also shorter. Some springs are supplied lighter to ensure function with standard loads.

As an example, I tested two 1911 handguns chambered in 10mm a couple of years ago. The first functioned with light loads intended for practice. It also functioned with full-power 10mm loads. The problem was that recoil was more than snappy! The slide’s end-of-motion during the recoil cycle has a lot of momentum and this creates recoil. The second 10mm pistol performed differently. The pistol failed to function with light loads, producing short cycles. Bullets of 180 grains at 1050 fps simply would not reliably cycle. On the other hand, 180- or 200-grain bullets at 1200 fps were perfectly reliable and recoil manageable. The former pistol, if fired extensively with full-power loads, would have suffered battering and perhaps peening of parts…eventually. Yet, if you were to carry the gun with defense loads — a mid-range 10mm — the pistol would function. For hunting and full-power loads, the other 10 mm with its 24-pound spring is preferred. By the same token, a 16-pound spring in a Commander .45 may slam the gun about. A 20-pound spring and a firm firing grip is the way to go. The rub is that you must keep a firm grip on the pistol with such a heavy spring.

So, what will different types of springs produce? The split (time between shots) is influenced by slide velocity. Shot splits and sight tracking are affected by muzzle flip. A heavy spring may dip the muzzle. This is called the second-round dip by competitors, and it is something that must be mastered, particularly by those who use a compensated pistol. Compensators are more popular than ever, and they change the recoil cycle.

When it comes to recoil springs and spring technology, it is roughly comparable to the shock absorbing springs in your vehicle. Some vehicles have a soft ride; some have a hard ride but handle bumps in the road and potholes more efficiently. While many malfunctions, including the common stove pipe and short cycle, may be due to an improper grip (the handgun must have a solid platform to recoil against), recoil springs may also be the culprit.

Another benefit of choosing high quality replacement springs is that they last longer than factory springs. A study of available 1911 recoil spring weights may be confusing. How, for instance, could a recoil spring vary from an example rated at 11 pounds to 20 pounds and still operate the same pistol? The answer is simple. The 11-pound spring is for the lightest bullseye competition loads. A 185-grain SWC at 800 fps will function the handgun with an 11-pound spring. A 16-pound standard spring in the Government Model 1911 will function with a 230-grain/850 fps load. For some shooters, an 18-pound spring works well with standard loads in the 1911 .45. A 20-pound spring is best with 230-grain/900 fps +P loads.

The rub is that a light load will not function at all with heavy springs. No surprise there. But you may batter your slide, slide stop, locking lugs, and barrel link with a too light spring. The pistol will probably function with a light spring and heavy loads, but the slide velocity will be “whippy.” The slide may outstrip the ability of the magazine to feed if the slide velocity exceeds design parameters.

Have the factories supplied improper springs in handguns? Certainly. The 10mm pistols mentioned had a difficult range of cartridges to handle. One maker went the light spring route, another the full-power route. A particularly common error is to supply lightweight 1911 handguns with too soft springs. They may function, but slide velocity may outstrip the magazine’s ability to feed.

When the Glock was introduced, the original recoil spring weight was 19 pounds. This was changed to 17 pounds in the 9mm. Many shooters had short-cycle issues in the beginning, and some of them may have been an unfamiliarity with semi-automatic pistols. The 17-pound recoil spring is better suited to a wide range of 9mm loads from 100- to 147-grain weight.

Let’s look at the different types of recoil springs.

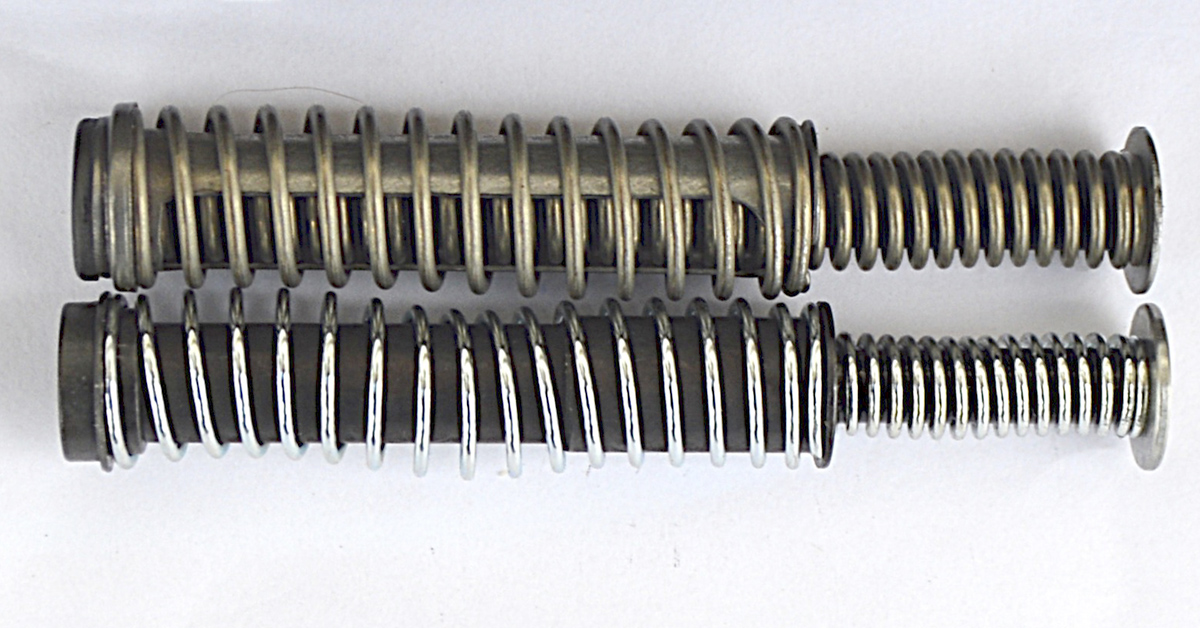

Flat wire springs are relatively recent in firearms design. The flat spring is reputed to offer better cushioning in recoil than a round spring.

Round wire springs are still most common in 1911-type handguns. They are the least expensive to manufacture. Aftermarket springs of the round type are available for Glock and other handguns.

Dual recoil springs are simply two springs that work together — sort of the nesting egg of recoil springs. These springs usually feature a heavier spring with a lighter spring inside the other. The new Colt system, also used in Savage 1911 handguns, has proven dependable and results in less felt recoil.

Variable rate recoil springs are the most difficult to design as they actually have different rates of strength along their length. I find the DPM-type recoil arrester superior, but the variable rate recoil spring was an important advancement.

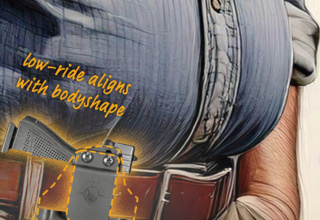

Captive, captured, and full-length recoil springs are attached to the recoil guide rod. The full-length guide rod of the 1911 is one example. They are easier to field strip in most modern automatic pistols although they may take some getting used to in the 1911 versus the original simple short rod and standard spring.

What may you gain with an advanced recoil system such as the DPM Systems combination? I have studied this device and others similar in operation at length. The primary advantage is in the way they prevent impact energy from damaging the frame and slide. This may not be a concern for many of us but if you are a competitor firing many thousands of rounds a year or if you have a heavy training schedule, the goal of limiting wear and recoil becomes paramount. The combination is designed to not interfere with normal extraction and ejection but to begin to arrest movement only after the spent cartridge case is in the air. Since the force of the slide is softened, the resulting momentum doesn’t impact the grip and the wrist. A locked wrist is essential to controlling recoil and, as a result, recoil energy is smashed back into the hand — actually accelerated from a loose and improper grip. Reducing muzzle rise is apparent as well.

On another note, the Glock pistols I have experienced function problems with have been older, well-worn examples — usually .40 caliber — in need of spring or slide stop replacements. But a single, long-slide Glock 9mm had given me trouble. This piece did not function, having intermittent short cycles with a wide range of ammunition even after I changed the recoil spring assembly. I plugged in a DPM system as an experiment. The pistol went from an aggravation to a match winner. It would be a long time before I trust it for defense use, yet it has been running now for several months.

Consider upgrading your spring system if you are after the last degree of performance. For the demanding shooter, the time and money are well spent.

Check This Out

During this test and evaluation period, I enjoyed a positive experience with a relatively new tool from Real Avid. The Smart-Assist Quick-Connect System may be used with a Real Avid Master Gun Workstation or on its own. I mounted it to the work bench before proceeding, sometimes taking it to the desk. The system features a 180-lumen work light with several pushbutton settings, a five-inch magnifying glass, and a cell phone holder. The device — I resisted calling it the Octopus but the resemblance is obvious — offers strong adjustable arms. As for the cell phone holder, no, I don’t talk to the Pretty Girl as I work. Like many others, I often watch instructional videos on assembly and disassembly as well as mounting certain accessories. About half are useless, some are dangerous, and some are particularly good. It doesn’t take long to get the better types. This is a neat accessory — a tool in itself — and another example of Real Avid’s immensely practical but out-of-the-box thinking.