TRUGLO’s TFX Series sights deliver maximum visibility and rapid sight picture acquisition in any light condition.

by Robb Manning

If you carry a handgun, be it for personal protection or duty, there’s a good chance that when you need it, it’s going to be in low light conditions. That’s how bad guys roll. They typically commit their crimes in the evening, on dark streets, in alleyways, behind buildings, indoors…you know the drill. Thus, equipping your carry gun with night sights isn’t optional, it’s mandatory.

There are many aftermarket night sight options to choose from, and while most original equipment night sights are very good, some are better than others.

BUILT FOR SERIOUS DUTY

TRUGLO has been around for a long time, starting with products that use fiber-optics in the design. Then they added Tritium sights to their lineup, eventually fusing the two into the TFO sights that incorporate Tritium and fiber-optics.

Recently, the company introduced the TFX series sights called the Tritium Fiber-Optic Xtreme. These take TFO technology and enclose it into a super-tough capsule. The capsule works two-fold. First, it protects the two illumination components (fiber-optics and Tritium vials) from cleaning solvents, oils, and other elements. Second, it locks them together, so they are always in-line and always touching each other to ensure maximum brightness.

The TFX series handgun sights have a lot going on that I really like. For starters, the sights are heavy duty. Both front and rear sights are CNC-machined using steel. Polymer sights can become damaged, like when dropped, but it’s a heck of a lot harder to damage steel sights. The sights stay secure on your gun, as well. The rear sight is installed like other dovetail sights, but TRUGLO incorporates a set screw to tighten it in place once installed. It’s not going to drift on its own. Given that the precision machining of dovetails is not equal amongst gun companies, the set screw ensures the rear sight stays in place no matter how loose the tolerances are in the dovetail slot on the slide.

The TFX series advantage is that it uses dual methods for light transmission. At the rear of the sight (towards the muzzle end of the gun) is a Tritium vial, and a fiber-optic element is in front of that (towards the rear of the gun). The Tritium glows constantly and is directed towards the shooter via the fiber-optic. The fiber-optic also collects ambient light and directs it towards the shooter. The brightness of the fiber-optic changes under varying light conditions, and the brighter the light, the more light it’s going to collect. This makes the sights brighter and thus easier to acquire in high ambient light conditions. The Tritium, of course, kicks in when operating in low light conditions. Thus, the TFX fusion of fiber-optics and Tritium delivers a sight that performs under both conditions. As a rep from TRUGLO told me, “We makes Tritium-only sights that are better at night, and we make fiber-optic-only sights that are slightly better in daylight, but TFX uniquely combines the best of both worlds.”

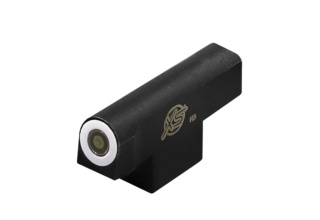

TRUGLO makes front sight acquisition even faster by placing a ring around the front sight dot, which they call the focus-lock ring. It works well because in bright light, your eyes do pick it up much quicker than they do sights without it. This is one of the differences between the TFX standard model and the TFX PRO. The TFX PRO uses a high-contrast orange ring, which really pops out at you, and the TFX uses a white ring (though a rep for TRUGLO told me that color can vary in certain places).

DIFFERENCES: TFX VS TFX PRO

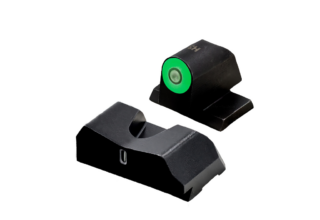

In addition to the high-contrast orange ring, there are two other differences between the standard TFX and the TFX PRO, the first one being the PRO rear sight has a flat/angled front in case your off-hand is injured and you need to charge the slide by hooking the sight onto something. The other difference is that the PRO rear sight has a U-notch instead of a square. The U-notch works better with the round dot on the front sight for quick sight alignment. It’s like putting a round peg in a square hole—your brain isn’t comfortable with that and can take a split second to process the alignment of a round dot with a square notch.

With an MSRP of $166 for the TFX and $178 for the TFX PRO sights, the difference between the two comes down to user preference. If you prefer a high contrast orange front sight, U-notch rear sight and/or a flat-front rear sight for one-handed slide manipulation, the PRO is the better choice. In reality, it’s more of a two-choice difference with the U-notch and high-contrast orange front sight dot because I can’t really picture anyone—armed citizen or law enforcement—that would say, “Nah, I would prefer to have a round-front rear sight so it’s harder to rack the slide if my weak-side hand gets jacked-up.” There might be other considerations that would make them go with the rounded front edge on a rear sight but having a “Plan B” to get your gun back up and running isn’t one of them.

I can’t see a big application difference between the two sights, with one being more suitable for CCW and the other for duty/tactical. I know for me and my carry guns, if given a choice, I’ll take a flat-front rear sight for one-handed slide manipulation, so I don’t see it being a CCW vs. duty thing.

There’s a lot to like about the TFX series of sights, and they have a lot of positive features; however, they’re not perfect for every application. If you plan on using them as a backup to optical sights, you won’t be able to do so since they won’t work with MOS configured slides. Let me rephrase that—they’ll work with the baseplate installed, but you won’t be able to remove the baseplate, and they won’t fit with optics. The problem is that in order to get optimal brightness, the fiber-optic requires length to collect light. Since you don’t want to extend the sight rearward past the back of the slide, the sight must be lengthened in the front. The result is that it covers a good 1/4 inch of the optics cut.

I didn’t take this into consideration when I mounted the sight the first time, and when I was done, I realized my mistake. Removing the sight left noticeable scuff marks in the Cerakote job where the sight was drifted on and off. It’s a non-issue if you have a non-optics-cut slide, but if you do, take this into consideration. For pistols with an optics cut, TRUGLO makes a Tritium PRO sight which doesn’t use fiber-optic, so the sight is not as long.

You’ll find the same issue with the front sight and slides that have a forward top slide cut, such as the G34. The front sight will protrude over the slide cut.

INSTALLATION

For this article, I installed the TFX sights onto a GLOCK G42 and the TFX PRO sights onto a GLOCK G26 Gen4. TRUGLO provided the sights, along with the TRUGLO GLOCK sight install tool.

Installation is straightforward and it doesn’t make a big difference if you start with the front or rear sight. Of course, you should always make sure your GLOCK is cleared before doing any work on it, and you’ll need to field strip it prior to the installation. You just need the slide, not the barrel or recoil spring.

To install the front sight, first remove the current front sight mounted to the gun. It’s just a matter of unscrewing the front sight screw using the front sight tool. Once the screw is out, if the front sight doesn’t just fall off, give it a little nudge and it will pop out. Position the TFX front sight into the same hole, use the front sight tool to line up the screw with the hole, and then turn it into place.

I recommend using a drop of blue Loctite on the threads before installing the screw. It’s optional, but you can also go a step further by placing a drop of Loctite on the bottom of the sight prior to pushing it into the slide hole. When tightening the screw, make sure the sight stays parallel with the slide edges, keeping it aligned with the rear sight. Small front sights like the GLOCK OEM sights aren’t as noticeable if they’re canted, but these sights are long, and if it’s not aligned, you’ll notice.

For the rear sight, make sure the installation tool has the proper lock plate installed. The Slimline GLOCK models (G42, G43, G43X, et cetera) use lock plate B (plus the spacer and lock knob bushing). All other GLOCK models use lock plate A. Slide the frame onto the plate, just like you would slide into onto the frame slide rails, until the rear sight is centered (fore to aft) on the drifter, and then tighten the slide onto the tool until snug (but not too tight), using the knob at the bottom of the rear sight tool. As you do this, make sure the slide and sight are perpendicular with the press—it’s best for it to not be canted.

Rotate the press so that the sights are drifted off, going from left to right. Once off, position the TFX rear sight at the right edge of the dovetail on the slide, making sure to first loosen (but not remove) the rear sight set screw. Move the press as needed so you can position the sight. Use your fingers to push the sight into the dovetail to get it started. Rotate the press until the right finger touches the right edge of the sight. Making sure the slide is still perpendicular with the press and that the dovetail notch is still centered fore to aft, carefully but firmly rotate the press to put pressure on the rear sight and drift it into place. Try to get it centered as close as you can, eyeballing it by using the edges of the dovetail notch. GLOCK slides are perfectly flat on top, and the edges where it starts to round into the side walls presents good reference lines to center most sights.

Once you’re happy with the placement of the sight, rotate the press so it is centered on the top edge marking, loosen the lock plate knob, and then slip the slide off the plate. At this point, I like to use calipers to measure both sides of the rear sight to ensure it is centered. If you’re satisfied with the position, apply a drop of blue Loctite to the set screw and twist it into place until tight but don’t over tighten. Before I Loctite anything, I prefer to take it to the range to see how it shoots. If it’s off to the right or left, then I can drift the rear sight for adjustment (that’s why I take my tool to the range).

TRUGLO SIGHT INSTALLATION TOOL

The TRUGLO GLOCK sight install tool worked well. It’s well built and solid—an important a sight install tool feature! The plate functions like the slide rails on the GLOCK’s frame, so you just slide the GLOCK’s slide onto the plate and then tighten the knob to secure it in place. The tool drifts the sight onto the slide efficiently and with minimal effort. I’d say it’s one of the better sight install tools I’ve used, though it is limited to just GLOCKs. The tool has tick marks so the press can be centered on the tool, however, it would be nice if additional markings were present to get a more accurate measurement for centering the sight on the slide instead of eyeballing it.

The front sight tool that comes with the kit is functional. If I have only one complaint, it’s that it’s not magnetized. The front sight screw is tiny, and you must eyeball the sight hole in order to insert it, which means the front sight tool is best positioned screw-side pointed down. With no magnet, this process is a little more difficult.

The front sight tool didn’t work the best with the G42. For removal, the tool’s stem wall that holds the screw head is too thick and there isn’t enough room on the slide between the front sight screw head and the front wall of the slide. For this, I used a GLOCK front sight tool. But once the original sight was off and I was installing the TFX, the TRUGLO front sight tool worked fine. Possibly the screw on the TFX sight is positioned back slightly from the OEM sight, giving enough room for the tool to center on the screw head.

FINISHING UP

For most firearm sight reviews I head to the range to test them, but due to time constraints, I wasn’t able to do so for these sights. With that said, however, this article is more about sight acquisition under low and bright light capabilities and installation—not so much about accuracy. These are self-defense/duty sights, after all, not target sights.

So in lieu of range time, I made do with some dry fire time in front of a mirror. In all honesty, this is probably one of the most underused and under-appreciated forms of training for self-defense. Since most ranges have rules against drawing from the holster, dry fire training at home can be quite useful.

I practiced using different levels of ambient light intensity, and found these sights functioned exactly as advertised and as intended. Sight acquisition was fast, so I was able to get the sights aligned and on target efficiently and without a lot of wasted movement. That equates to increased speed.

There’s a lot of options on the market for night sights, and as a gun writer, I have access to most of them. As a testament to the TRUGLO TFX series sights, they have found a home on two GLOCKs that I carry and trust my life with.

- TESTED: Beretta PMXs 9mm Pistol - July 26, 2024

- The Correct Way to Clean a GLOCK - January 15, 2024

- Concealed Carry Guns: How Important is Ergonomics? - December 11, 2023