Famed precision trigger manufacturer puts a true competition spin on this peak performer…GLOCK owners smile

by Rob Reaser

If you’ve been in the firearms world for any length of time, Timney should be a familiar name. Since 1946, Timney has been an industry leader in the engineering and manufacturing of precision trigger systems, beginning with “sporterized” military rifles and now encompassing all the leading bolt-action rifle brands as well as select shotguns, ARs, and the 10/22 rimfire. Surprisingly, handgun triggers have not been included in Timney’s long production history.

Well, all that changes this year. In parallel with the company’s 75th anniversary, Timney Triggers marks another milestone with its first polymer-frame pistol trigger system called the Alpha Competition Series. As you might expect, the platform for this new endeavor is the always-popular GLOCK.

Aftermarket triggers for the GLOCK system are nothing new, of course, but most are variations on the factory trigger theme, with refinements mostly centered on trigger bar geometry, trigger shoe adjustability and design, and alternate spring rates. Timney’s approach to making a better GLOCK trigger took a somewhat different turn. Rather than the “take what works and make it better” angle, the Timney Alpha Competition Series trigger began with directed input from GLOCK shooting team captain Shane Coley. Hey, if you’re going to step up an iconic brand like GLOCK, who better to define the mission than a National and Team World Champion shooter who runs GLOCK pistols every day for a living?

Shane joined forces with Timney’s Director of Product Development Calvin Motley to work out a trigger system that combined Calvin’s engineering prowess with Shane’s must-haves for fast, accurate shooting in a competition environment:

- Reliability (an absolute requirement for any firearm)

- Reduced pull weight

- Short reset

- Positive reset (ample spring pressure to push the trigger out and to maintain good finger-to-trigger pressure during reset)

- Clean and consistent crisp break

- Consistent take-up on the pull so that it’s easy to prep the trigger for the shot

These are, understandably, righteous goals of any match-grade trigger system. The question for Timney was how to get there and to do it better than anything that has come before. The envisioned system also needed to conform with Timney’s reputation for providing user-friendly drop-in installations and high quality and performance standards.

When it all shook out, Calvin, Shane, and the Timney team developed a GLOCK trigger system unlike anything else on the market. While it hit all the assigned performance benchmarks, it did so with a bit of reinvisioning of what a GLOCK trigger system could be.

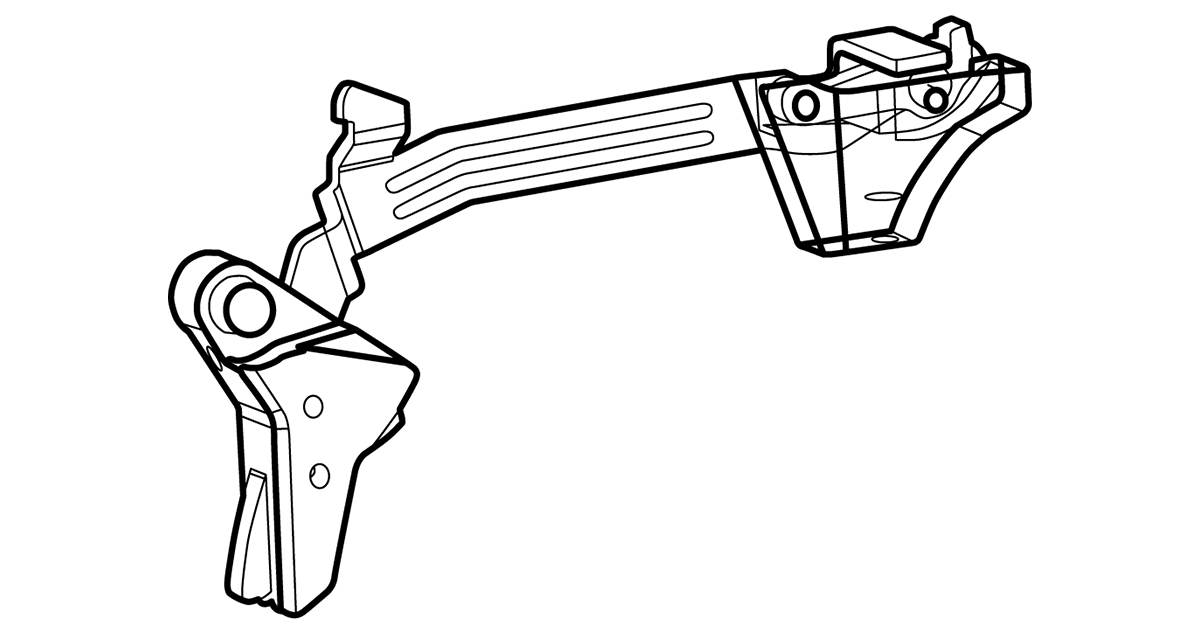

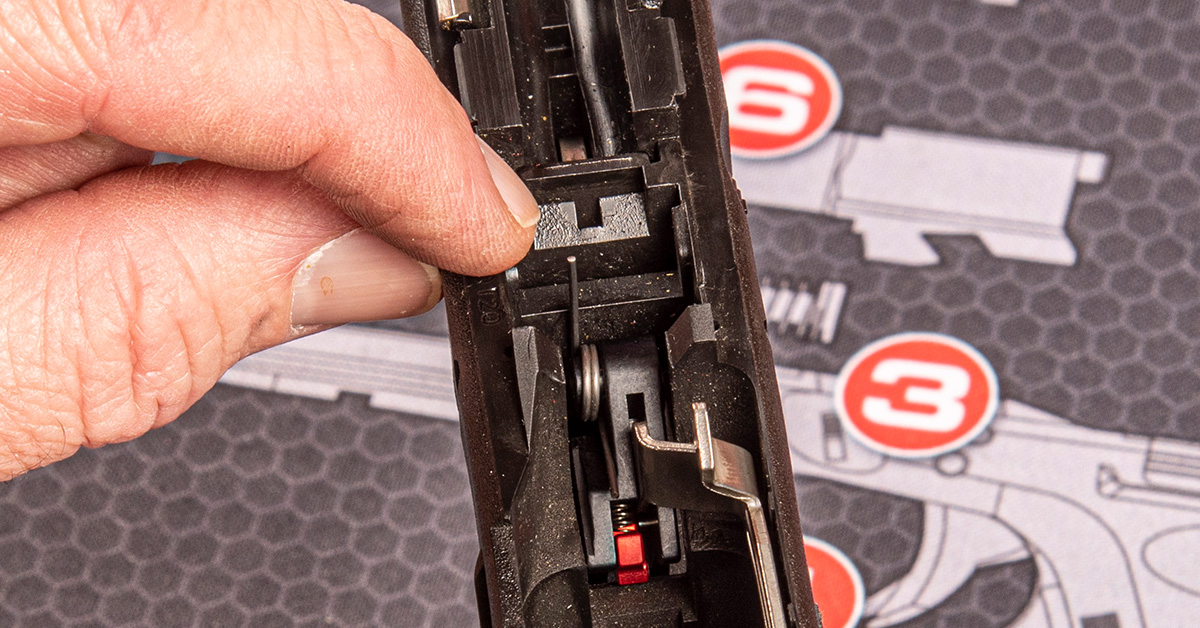

Those who know their way around a GLOCK trigger can see a couple of “huh?” differences from this simple diagram of the new Alpha Competition Series trigger. First is the two-prong spring wrapped around the trigger pin hole boss at the left side of the trigger shoe. Second is the sear module (Timney calls it a “receiver”) at the back of the trigger bar, where you would expect to see the trigger mechanism housing. The short version of this new design is that the trigger return spring in the Alpha system is now up front at the trigger shoe and actuates only the trigger shoe, not the entire trigger shoe/trigger bar assembly (as does the factory system). The factory “cruciform” design at the back of the trigger bar, which serves as an anchor point for the return spring and incorporates the sear for the firing pin lug engagement, is not present on the Alpha trigger.

Instead, the Alpha system’s receiver is a machined assembly that fits into the factory trigger mechanism housing. It incorporates a spring-loaded sear that engages the firing pin lug when the slide is pulled back and then moved forward (either manually or during recoil). This system keeps the firing pin cocked in its rearmost position.

When the gun is ready to be fired and the trigger is pulled back, instead of using a trigger bar extension to push the firing pin rearward, the rearward pull of the trigger moves the Alpha’s trigger bar tab back and down into the drop safety slot of the trigger mechanism housing.

As the bar drops, it pushes down on the sear, allowing the sear to disengage from the firing pin lug. The firing pin is then propelled forward under spring tension to strike the primer.

Once you see the Alpha Competition Series in action and wrap your head around this design, you realize that this is one of those uncommon bursts of ingenuity that makes you ask, “Why didn’t someone think of this before?”

The Alpha not only simplifies the GLOCK trigger system, but it delivers on the essential attributes that guided its design. The new trigger return spring offers a much more positive feel during reset than the original design. The trigger pull weight is reduced to 3 lbs. because the trigger system is not compressing the firing pin spring. The break is significantly crisper—a credit to the more precise sear design, Teflon nickel (NP3) treatment of the trigger bar and sear, and elimination of the “rolling break” inherent to the original GLOCK trigger system. As for the reset, it absolutely redefines “short.”

Installing the Timney Alpha Competition Series Trigger

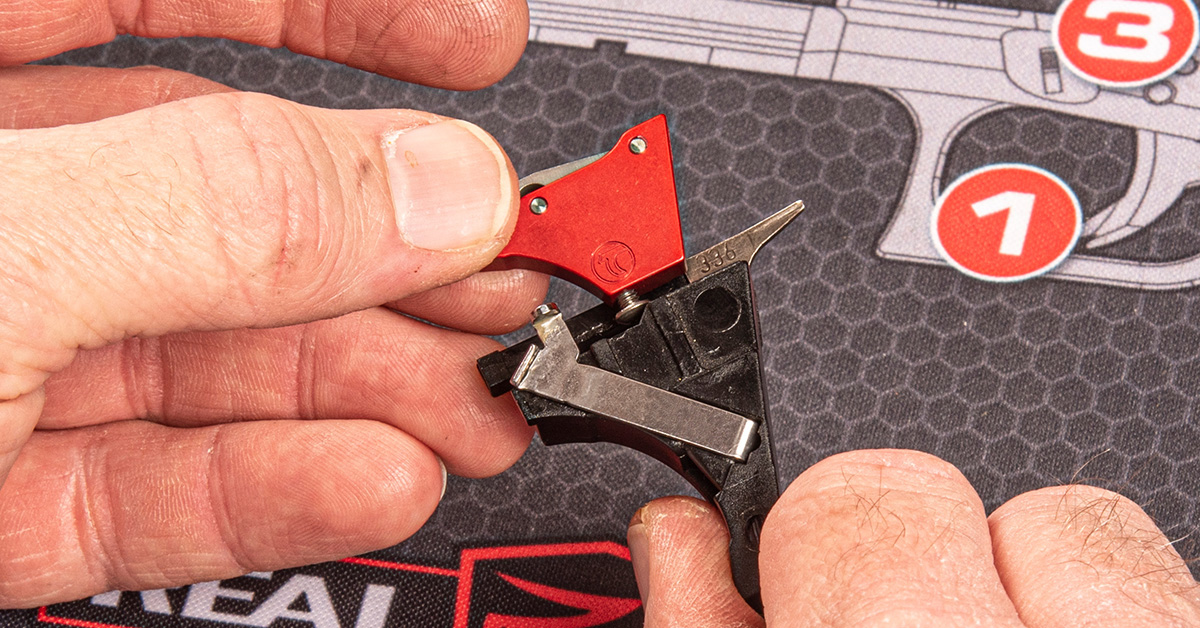

This is the sum of the Alpha Competition Series kit. It includes the trigger shoe/trigger bar assembly, the receiver (contains the spring-loaded sear), trigger return spring, and a small tool set to complete the work.

As always, when working on firearms, remove the magazine and ensure there are no cartridges in the chamber. Remove the slide assembly from the receiver.

Push out the locking block and trigger pins with a GLOCK tool or punch, working from left to right. Here, we are using the Real Avid 4-in-1 Tool for GLOCK.

Remove the slide stop lever and spring assembly from the receiver.

Remove the locking block from the receiver.

Push out the trigger mechanism housing pin, working from left to right.

You can now remove the trigger system by lifting it out of the receiver.

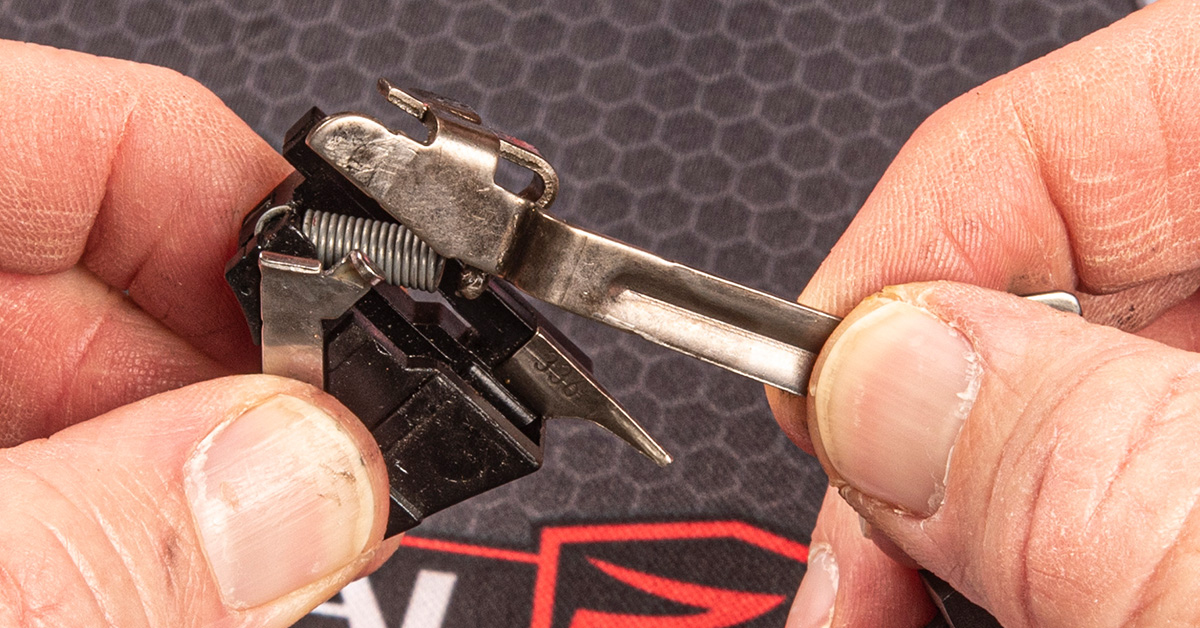

Release the trigger bar from the mechanism housing…

…and then disconnect the return spring from the housing.

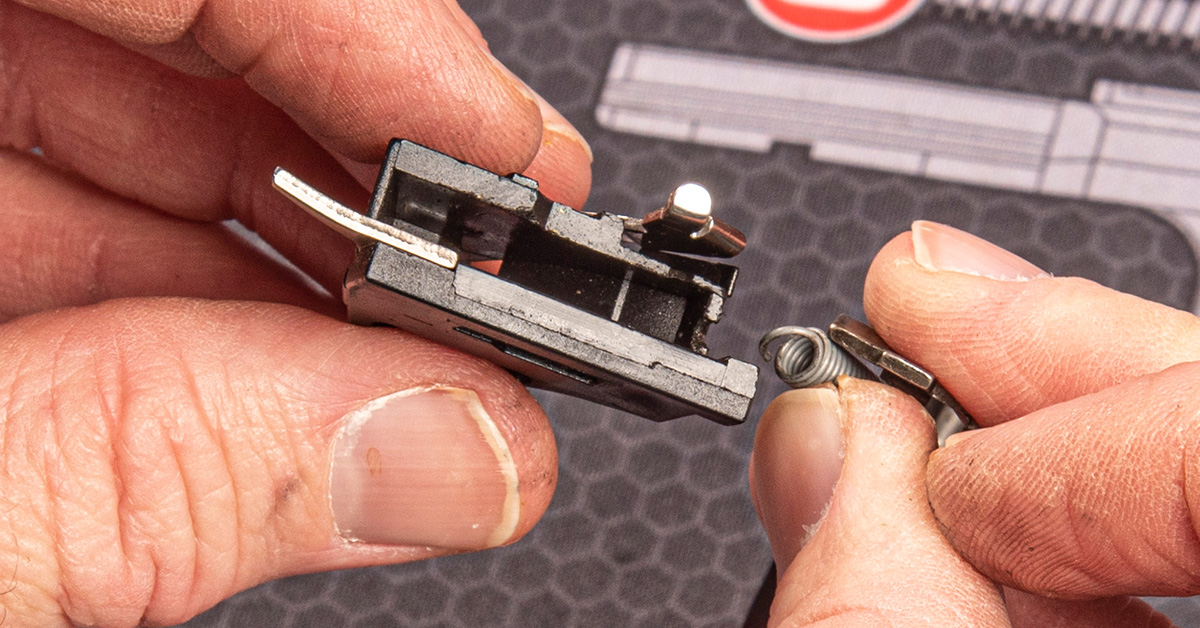

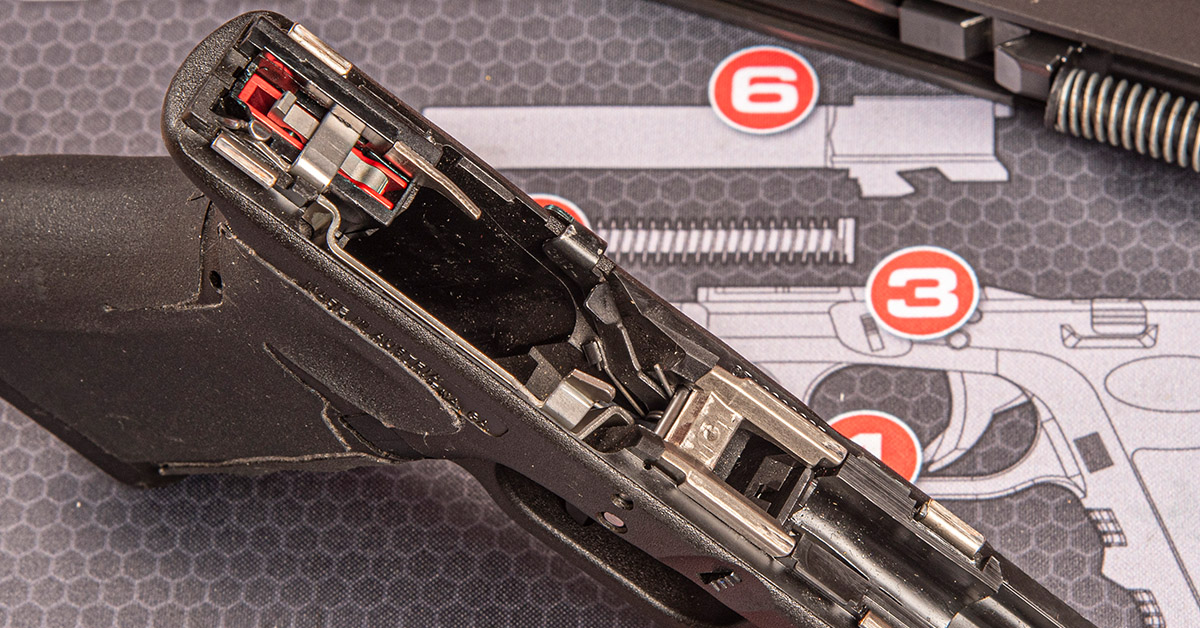

Insert the Alpha receiver into the stock trigger mechanism housing.

This small set screw secures the Alpha receiver to the trigger mechanism housing via clamping force. The kit includes a hex driver to tighten the screw. Be careful not to over-tighten and risk damaging the housing.

Place the trigger bar into position on the trigger mechanism housing as shown.

Drop the trigger system into the pistol receiver as a unit.

Orient the Alpha return spring as shown (with the “L” facing the back of the receiver) and position the coil over the trigger pin hole boss.

Place the locking block into the receiver but only push it halfway into position to leave room to manipulate the return spring upper arm. Use a small flathead screwdriver to pull the upper spring arm slightly toward the rear of the receiver while simultaneously pressing the locking block the rest of the way into the receiver.

Push the locking block pin halfway through the receiver, working from the right to the left. Pull the upper return spring arm down so that it clears the left-side pin hole and then push the pin the rest of the way into the receiver. The spring arm will be underneath the pin when properly installed.

Reinstall the slide stop lever between the receiver and the trigger. Insert a GLOCK tool or punch through the trigger pin hole on the left side of the receiver, capturing the slide stop lever and trigger. Use the GLOCK tool or punch as a slave pin to maintain parts alignment while you push the trigger pin into the receiver. Once installed flush in the receiver, make sure the slide stop lever is in the trigger pin groove.

Install the trigger mechanism housing pin, working from the right to the left.

The Alpha Competition Series trigger system is installed. Apply lubrication per your GLOCK owner’s manual.

We install an armorer’s inspection plate in place of the factory slide cover plate to observe the sear-to-firing pin lug engagement (arrow). On standard GLOCK trigger systems, we want to see a minimum 2/3 surface engagement between the rear trigger bar extension and the firing pin lug. The Alpha trigger system reveals 1/2 surface engagement between the sear and the firing pin lug. This is within design safety tolerances per Timney.

After replacing the slide cover plate (if removed for inspection), reassemble the pistol and perform a function check before returning the gun to service.

The Alpha Competition Series is designed to work with the following GLOCK Gen 3 and Gen 4 models:

- Gen 3 – G17, G17L, G19, G22, G24, G23, G34, G35

- Gen 4 – G17, G19, G22, G34, G35

To learn more about the new Timney Alpha Competition Series trigger for GLOCKs, go check out the product page.