Now it’s time for close evaluation of powder performance in developing an optimized load

by Lou Patrick

In Part 10 of this series, I had mentioned that we are currently in the experimental phase of load development. I went on to advise, when possible, to test powders of different burn rates because each different burn rate of powder will build pressure differently. Remember, powder is a propellant. Once ignited, it burns extremely fast and in a controlled fashion within the tight confines of the firearm’s chamber. Once the rear of the powder column is ignited by the primer, the powder begins to burn. This creates heat and pressure, causing the powder to burn faster while generating increasingly more heat and pressure. Although the pressures created do vary from cartridge to cartridge, they are quite high. The .308 Winchester cartridge, for example, has a maximum average operating pressure of 62,000 psi.

It is my opinion that the difference in how the operating pressure builds and subsequently how the rifle’s barrel reacts to it is what ultimately gives powder (more specifically, the powder’s burn rate) the greatest influence over the accuracy of the load.

As you look at the nine different powders pictured above, all are safe to use in loading the .308 Winchester cartridge with a 150-gr. bullet. While they are all safe, from an accuracy standpoint, most likely they will not all perform the same. The only way to know what will perform well in your rifle is to do some testing.

For those who are new to reloading and looking to purchase their first pound of powder, follow the guidelines set forth in Part 10 of this series. For those of us who have been reloading for a while, we tend to acquire more tools and supplies over the years. Looking at my current assortment of powder and how it applies to loading the .308 Winchester cartridge with a 150-gr. bullet, I decided to do a powder burn rate test using the powders pictured above.

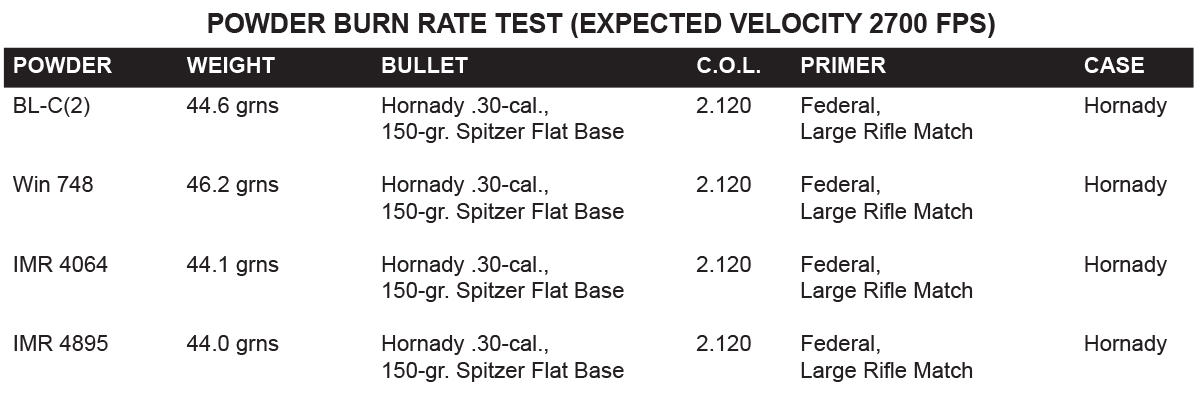

Five rounds were loaded using each type of powder pictured for a total of twenty rounds. Each cartridge was loaded using a Federal large rifle match primer, a Hornady 150-gr. Spitzer Interlock flat base bullet (#3031). All twenty rounds were loaded using Hornady once-fired brass from the factory ammo test performed in Part 5. The cartridge overall length as established in Part 9 as measured from ogive to case head was 2.120 inches. Each cartridge was loaded to achieve a muzzle velocity of 2700 fps. Getting the powder charge to achieve this target velocity can be rather difficult at the beginning, having yet to chronograph a reload. The 2700 fps muzzle velocity was also somewhat short of the maximum potential of this cartridge. This allowed us some margin of safety and some room to work with when we incrementally worked up the load to its maximum velocity. The goal here was to have each cartridge as identical as possible with the only difference being the burn rate of the powder used. When testing reloads, it is important to test only one variable at a time.

The importance of accurate record keeping cannot be over-emphasized. Unfortunately, as easy as this is, this is where many reloaders fall short. The following load data was entered into MTM’s invaluable Handloaders Log.

Since we are conducting a test, these cartridges will not be stored long-term. Rather than use a reloading label on the cartridge box, I used a piece of masking tape. This works well when using an MTM plastic slip top ammo box as the tape is easily removed afterwards. All that is needed at this time is to keep the ammo segregated into five-shot groups according to the powder being tested.

The purpose of this test is to isolate the possible performance differences that exist, or can exist, between the four different burn rates of powder being tested. Of course, we are lacking a fully equipped ballistics laboratory, so we are left doing the best we can with what we have. We currently have twenty rounds loaded. These twenty rounds are divided into four five-shot groups. Each five-shot group contains a different burn rate of powder; otherwise, these twenty rounds are as identical as can be achieved at the reloading bench.

I know…I had stated earlier in this series that five-shot groups are statistically irrelevant. No, I haven’t changed my opinion concerning 5-shot groups. I advise the use of five-shot groups during this test as a 20-shot group is simply not needed at this time. The purpose of this test is to identify the performance (accuracy) differences between the powders being tested to serve as an aid in powder selection. Using five-shot groups allows us to save some time and some reloading components while providing enough information to guide us in our final powder selection and ultimately load refinement.

Test Procedure

- Chronograph (optional) data is collected while firing each five-shot group.

- A total of 24 rounds of ammunition were needed for this test.

- Two targets are placed side by side on the target backer at 100 yards.

- The first shot from a cold, clean barrel is fired at the target on the right.

- A five-shot group using the same burn rate of powder is then fired at the target on the left. When firing, always monitor the signs of excessive chamber pressure as discussed in the Hornady reloading handbook.

- The target containing the five shot-group is removed and a new target put in its place.

- The barrel is cleaned following each five-shot group.

- Scope adjustments are not made during this test.

- Point-of-aim is always at the center of the target.

Powder Burn Rate Testing

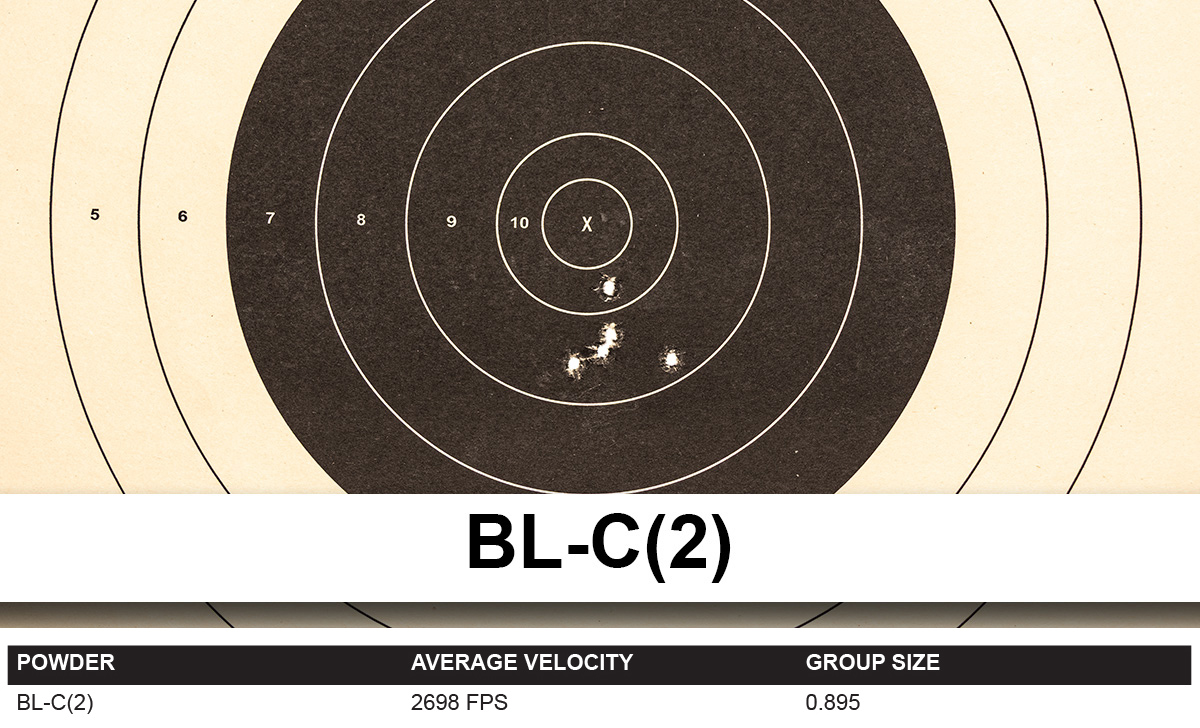

Following one fouling shot, this five-shot group was fired using BL-C(2) powder. Our five-shot velocity average is only 2 fps slower than our goal of 2700 fps. The barrel was allowed to cool as the target was being changed. The barrel was then cleaned prior to firing the next five shot group.

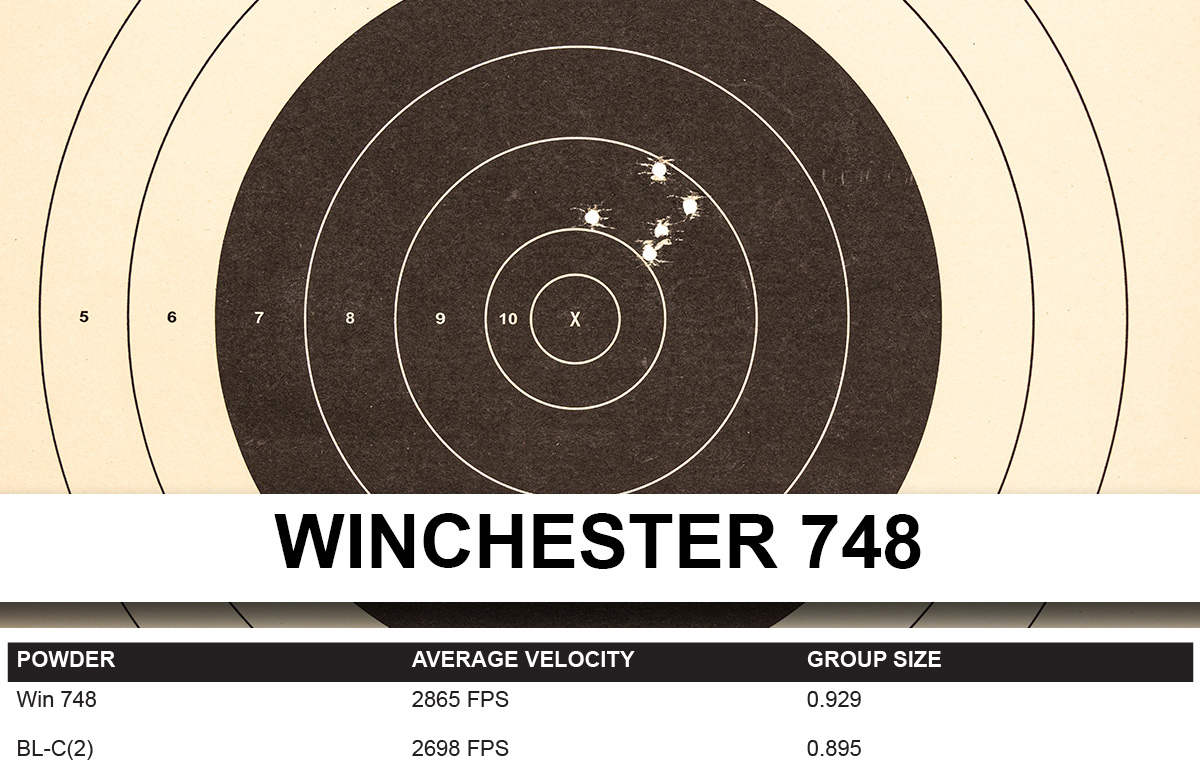

Following one fouling shot, this five-shot group was fired using Winchester 748. This load is 165 fps faster than our target velocity of 2700 fps. The group is .034 larger as compared to the previous group fired using BL-C(2). The barrel was allowed to cool as the target was being changed. The barrel was then cleaned prior to firing the next five-shot group.

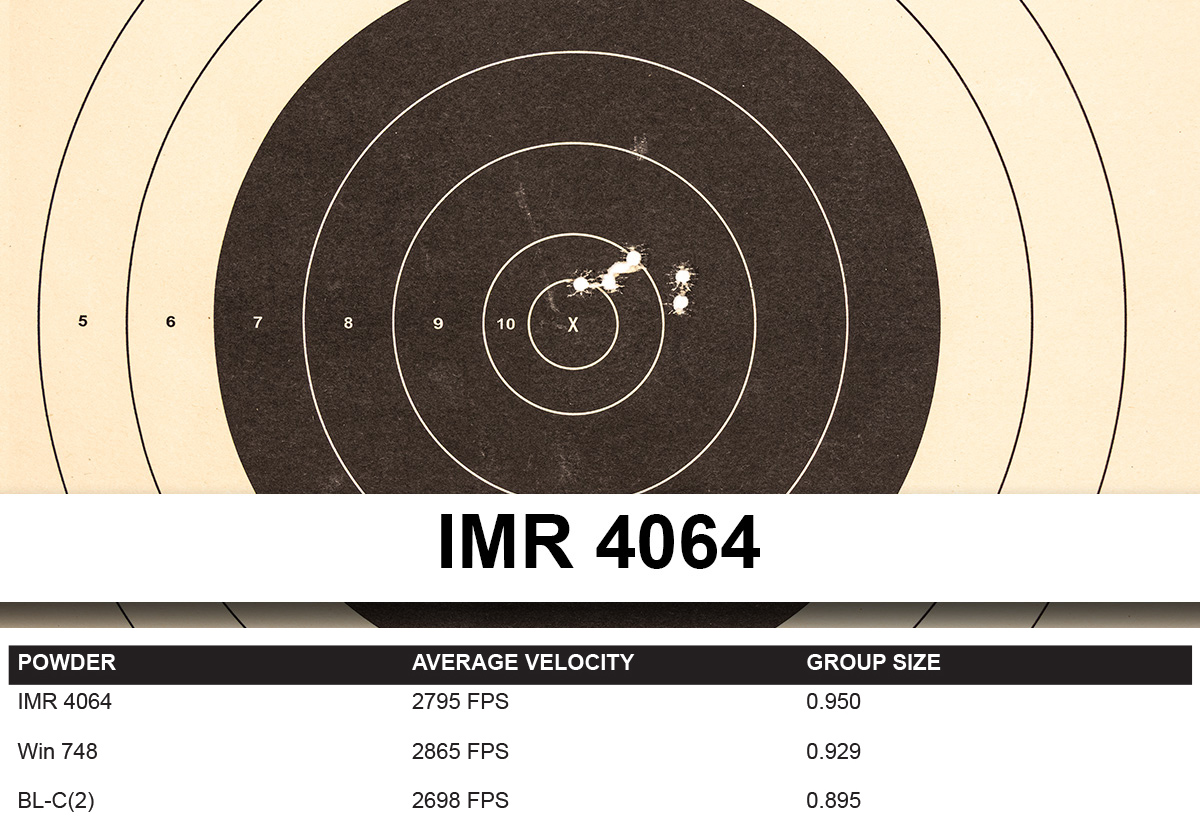

Following one fouling shot, this five-shot group was fired using IMR 4064. This load is 95 fps faster than our target velocity. At first glance, the group may seem to print tighter; however, it is .031 larger than the group fired with Winchester 748. The barrel was allowed to cool as the target was being changed. The barrel was then cleaned prior to firing the next five-shot group.

Following one fouling shot, this five-shot group was fired using IMR 4895. This load is 75 fps faster than our target velocity of 2700 fps. With a five-shot group size of .873, this is also the smallest group fired during this test. Looking closely at the five different targets, you’ll see that group size and shape, combined with the location at which the bullets impacted the target, are all different.

IMR 4895 is the accuracy winner of our powder burn rate test. Thus, we are going to continue to refine this load. Our previous test load contained 44.0 grains of powder, which puts this load 2.4 grains below the maximum of 46.4 grains as listed in the Hornady manual. In working towards the peak performance of this load, our next step is to perform what I refer to as a pressure test.

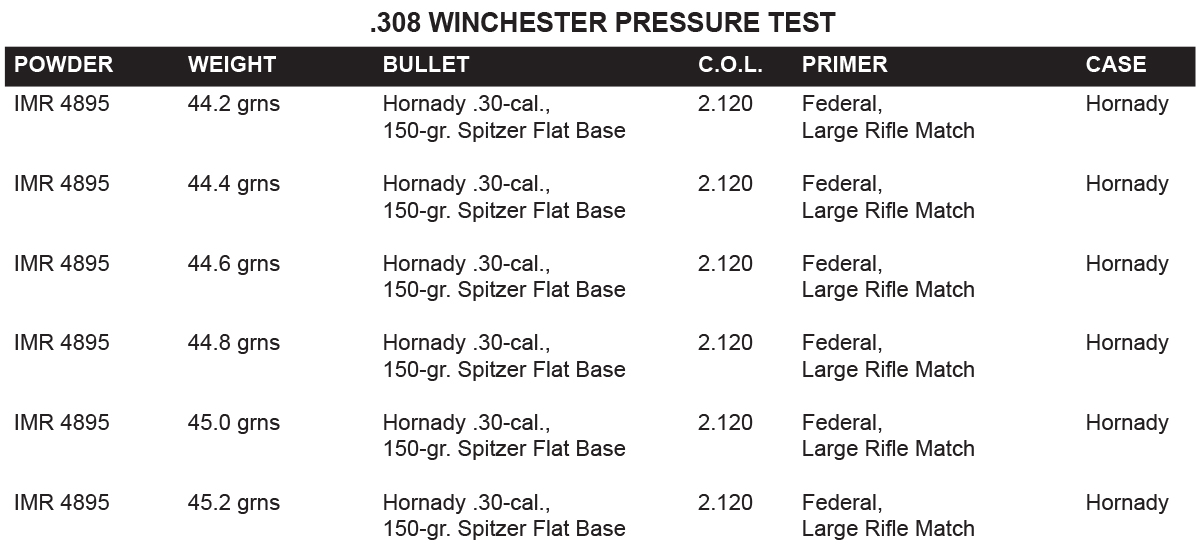

The brass was prepared and reloaded as discussed earlier in this series. The following data was entered into the reloading log book.

Six different powder weights of IMR 4895 will be tested in .2-grain increments. Three rounds of each different powder weight were loaded. Two rounds were loaded with 44.0 grains of IMR 4895 to serve as fouling shots for a total of twenty rounds. The only variation here is that of powder weight; otherwise, the cartridges are identical.

Using a makeshift masking tape label, the ammunition is segregated into three shot groups according to the weight of the powder charge.

Pressure Testing

The pressure test provides you with a means to safely reach the maximum potential of your reloaded ammunition. When working up a new load, it is always advisable to start with a low powder charge. We did this by using 44.0 grains of IMR 4895 during the powder burn rate test. With IMR 4895 being the most accurate powder that we had tested, it is now time to “work up” that load.

This “working up” is done during what I refer to as a pressure test and is accomplished by incrementally increasing the powder charge weight. As the powder charge weight increases, chamber pressure will also increase. Always placing safety first puts the focus of this test in monitoring for signs of excessive chamber pressure as discussed in the Hornady reloading handbook.

Test Procedure

- Chronograph (optional) data is collected while firing each three-shot group.

- A total of 20 rounds of ammunition were needed for this test.

- Two targets are placed side by side on the target backer at 100 yards.

- The first shot from a cold clean barrel is fired at the target on the right.

- Using the three cartridges containing the lowest powder charge, the first three-shot group is fired at the target on the left. Signs of excessive chamber pressure are monitored during firing. The test is terminated at the first sign of excessive chamber pressure.

- The target containing the three shot-group is removed and a new target put in its place.

- The barrel is allowed to cool between shot groups.

- The barrel is not cleaned during this test.

- Scope adjustments are not made during this test.

- Point-of-aim is always at the center of the target.

The process is then repeated, firing the next three-shot group containing the next step up in powder charge.

Safety first!

Just because Hornady’s test rifle safely fired 46.4 grains of IMR 4895 does not mean that all rifles will. Proceed slowly and cautiously. Terminate this test at the first sign of excessive chamber pressure.

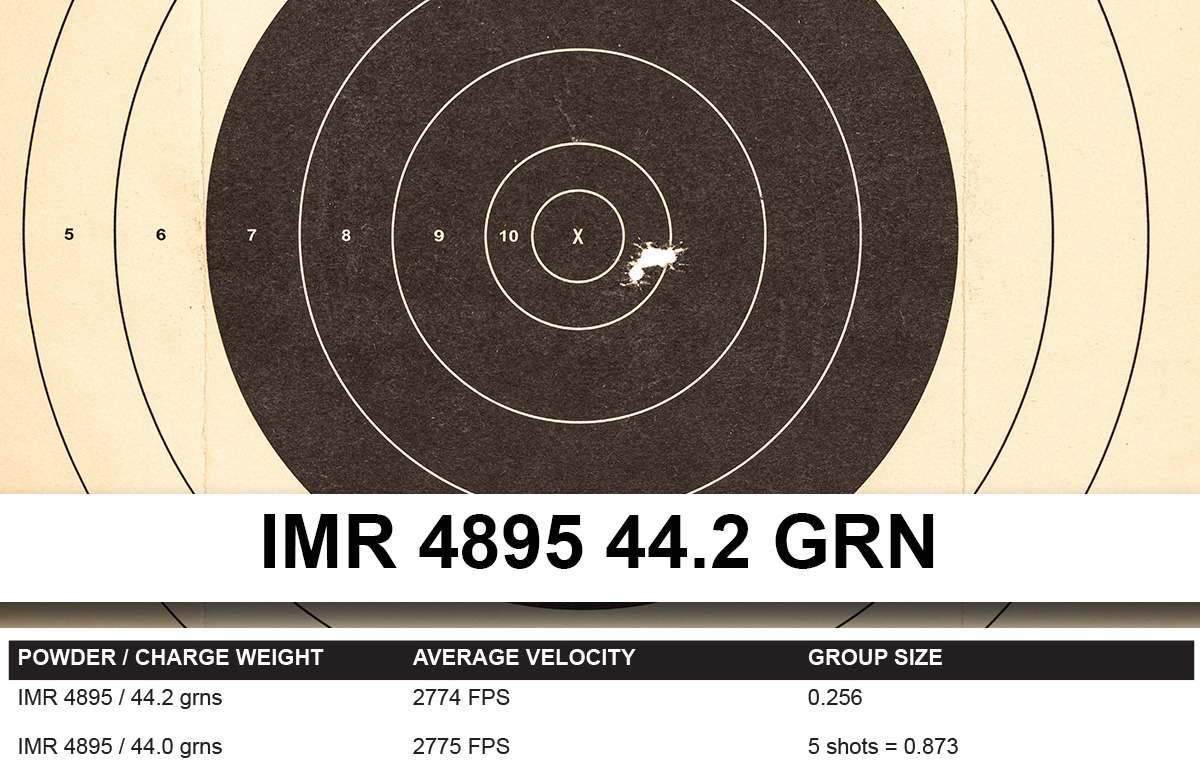

First things first: the goal of this test is to monitor signs of excessive chamber pressure as the powder charge is increased. The .2-grain increase in powder charge did not show any signs of excessive pressure. This allows us to continue with the test. Gathering velocity and accuracy data from a three- or five-shot string can be misleading. We currently have a .2-grain increase in powder charge that has provided for a 1 fps loss in velocity as compared to the five-shot average fired during the burn rate test.

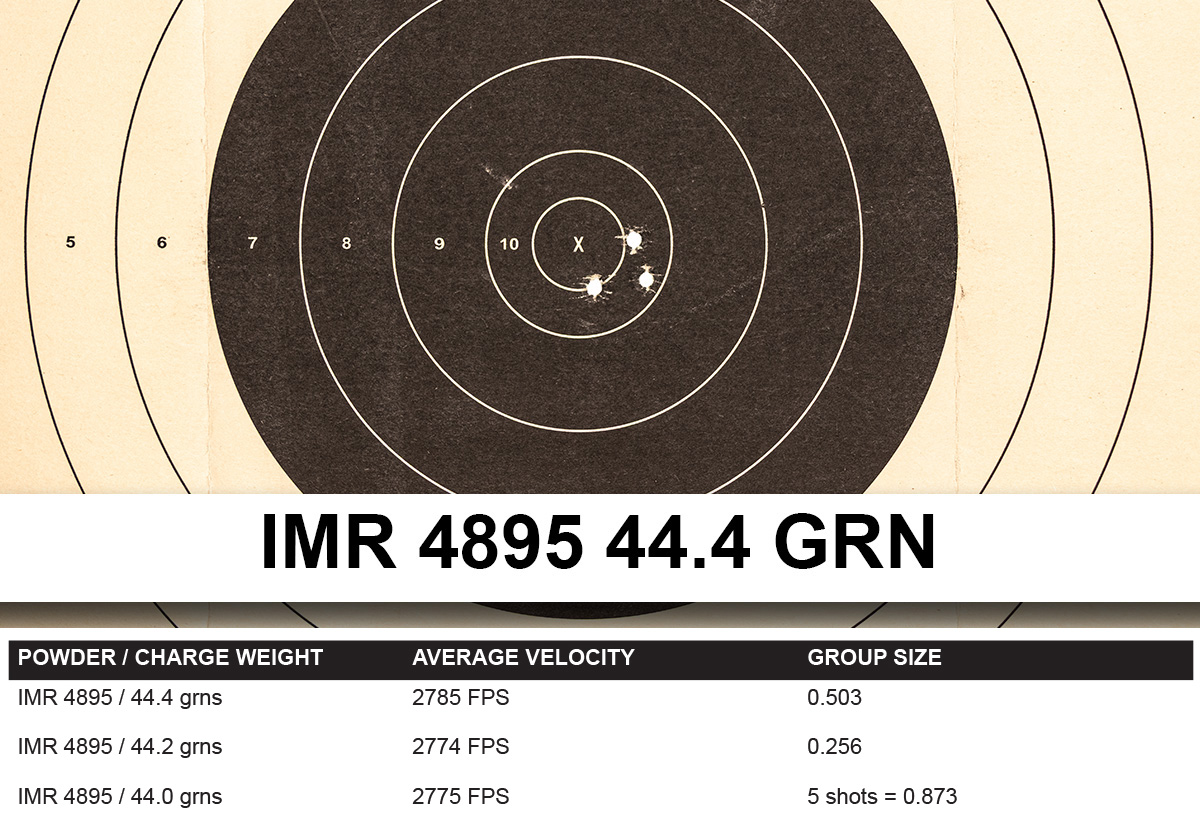

The 44.4-grain load did not show any signs of excessive pressure. You can’t help but notice that the shot group is about twice the size as the 44.2 grain load; however, these are three-shot samples, which are not going to tell us much about the overall accuracy of the load. More importantly, look at the group shape (triangular) and the location at which the bullets impacted the target.

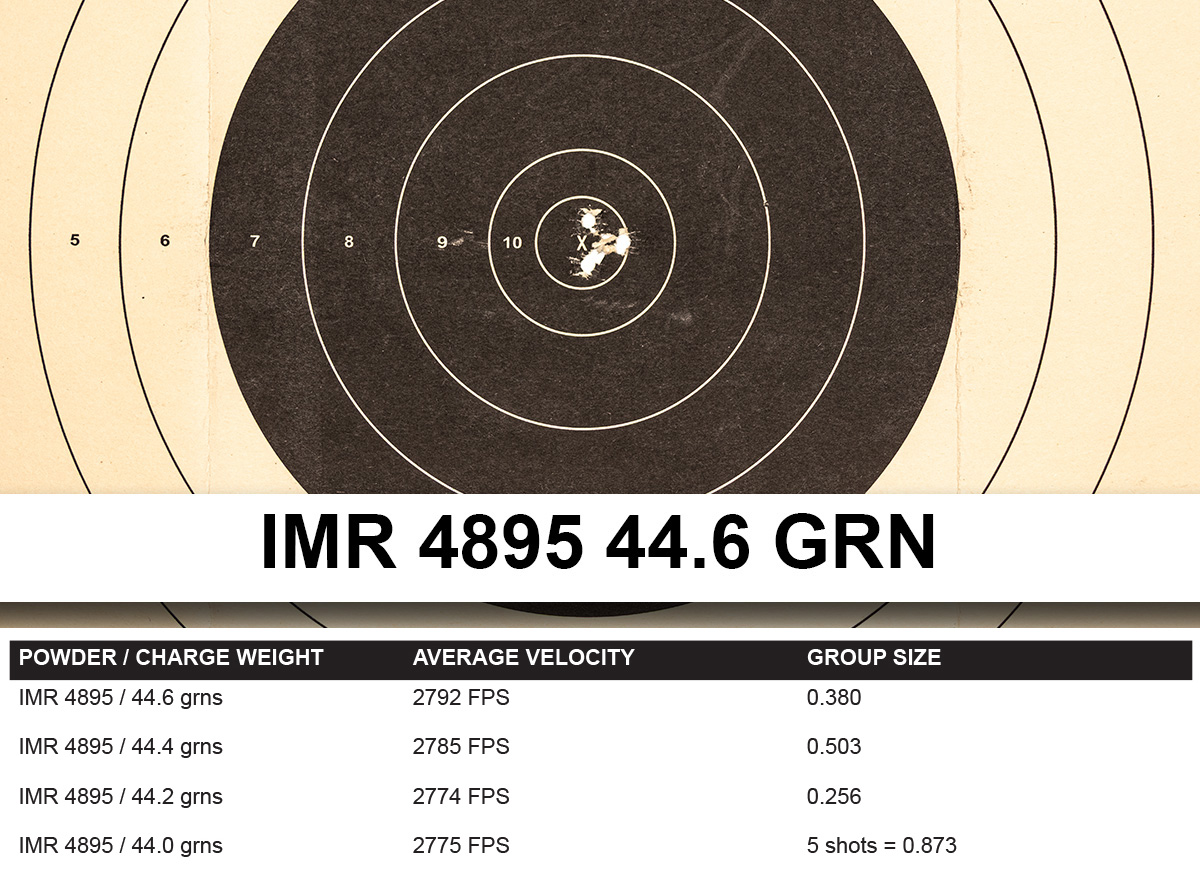

The 44.6-grain load did not show any signs of excessive chamber pressure. The group is now smaller, remains in a somewhat triangular shape, and has impacted the target a little higher and to the left. Much of what we see on target will most likely fall within the normal shot dispersion of the final load.

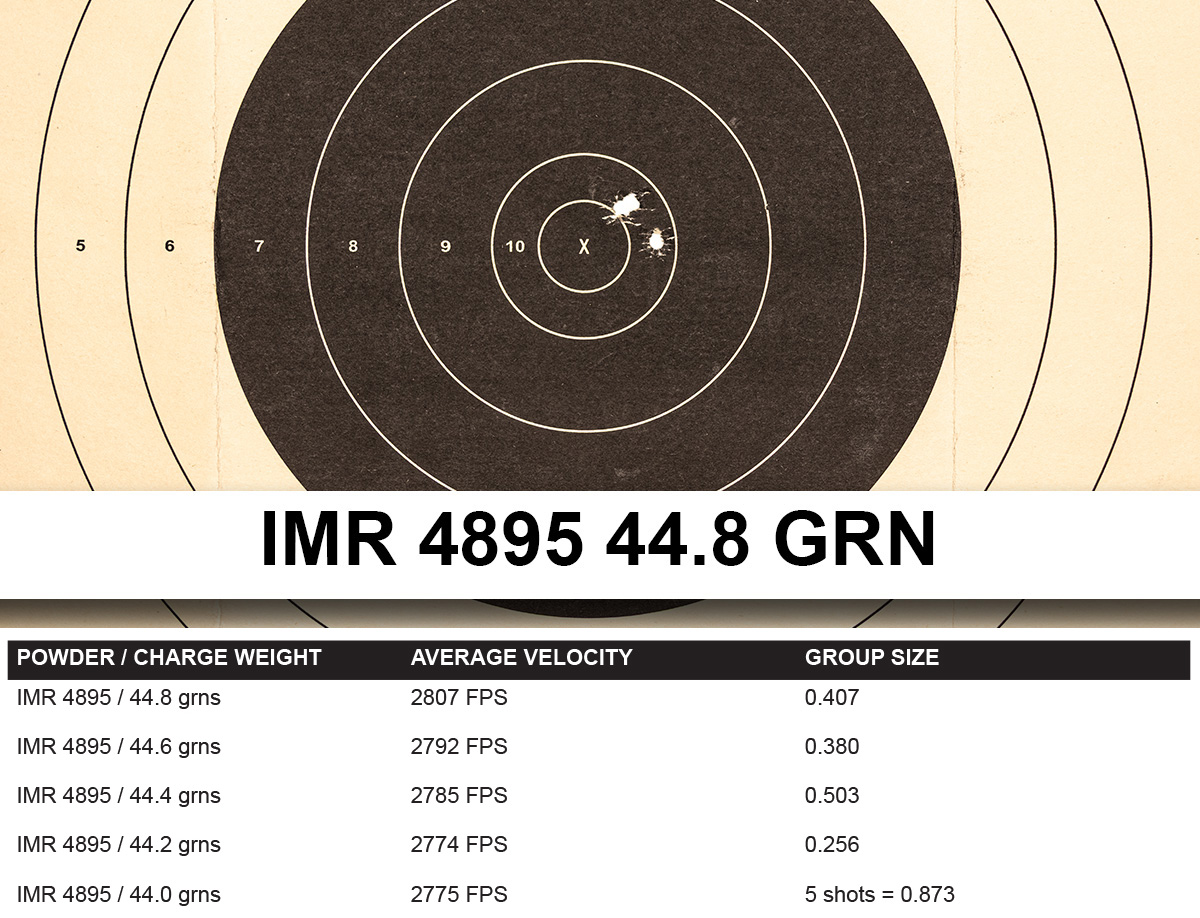

The 44.8-grain load did not show any signs of excessive chamber pressure. The shot group remains in a triangular shape, impacting the target in the same general location.

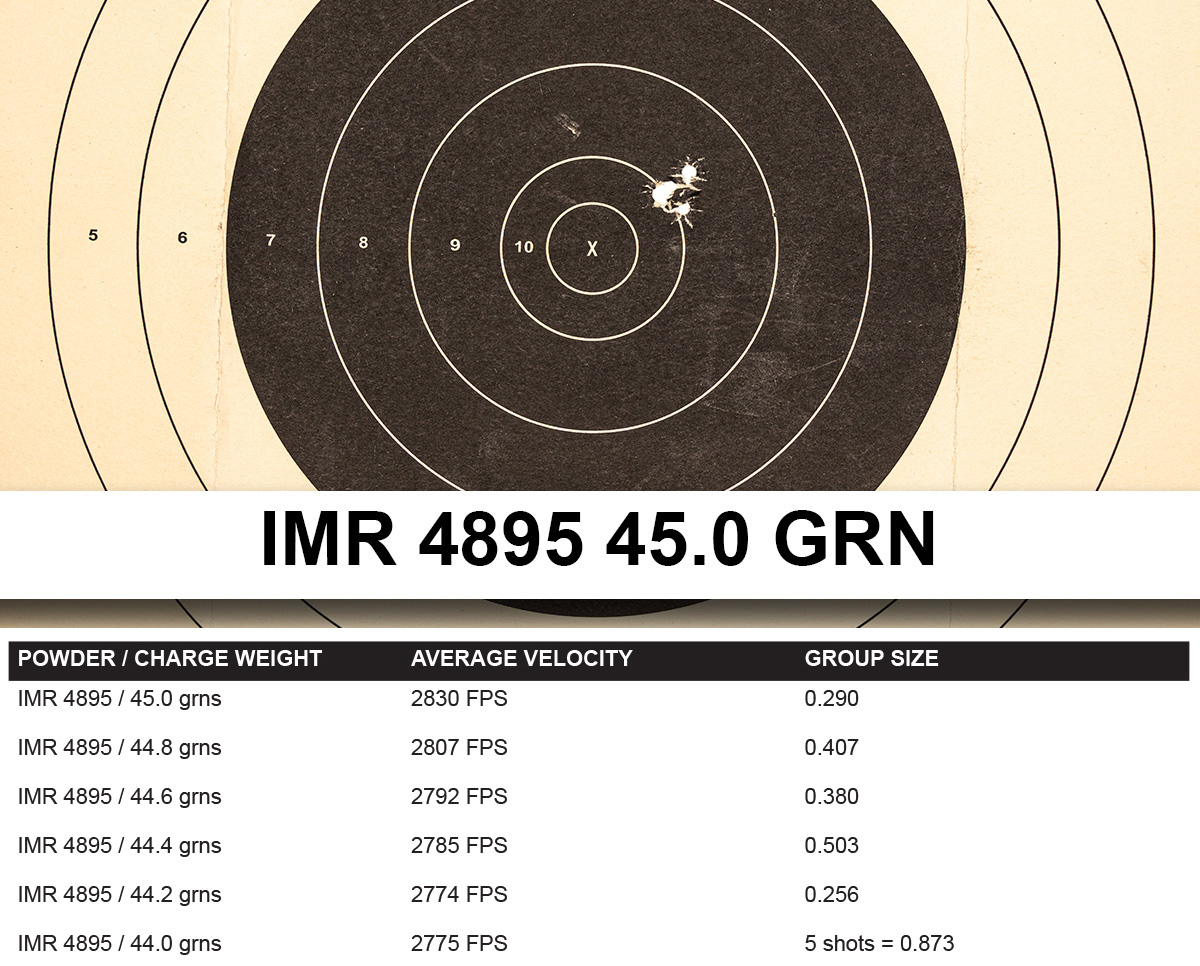

The 45.0-grain load did not show any signs of excessive pressure. The shot group remains in a triangular shape, impacting the target in the same general location.

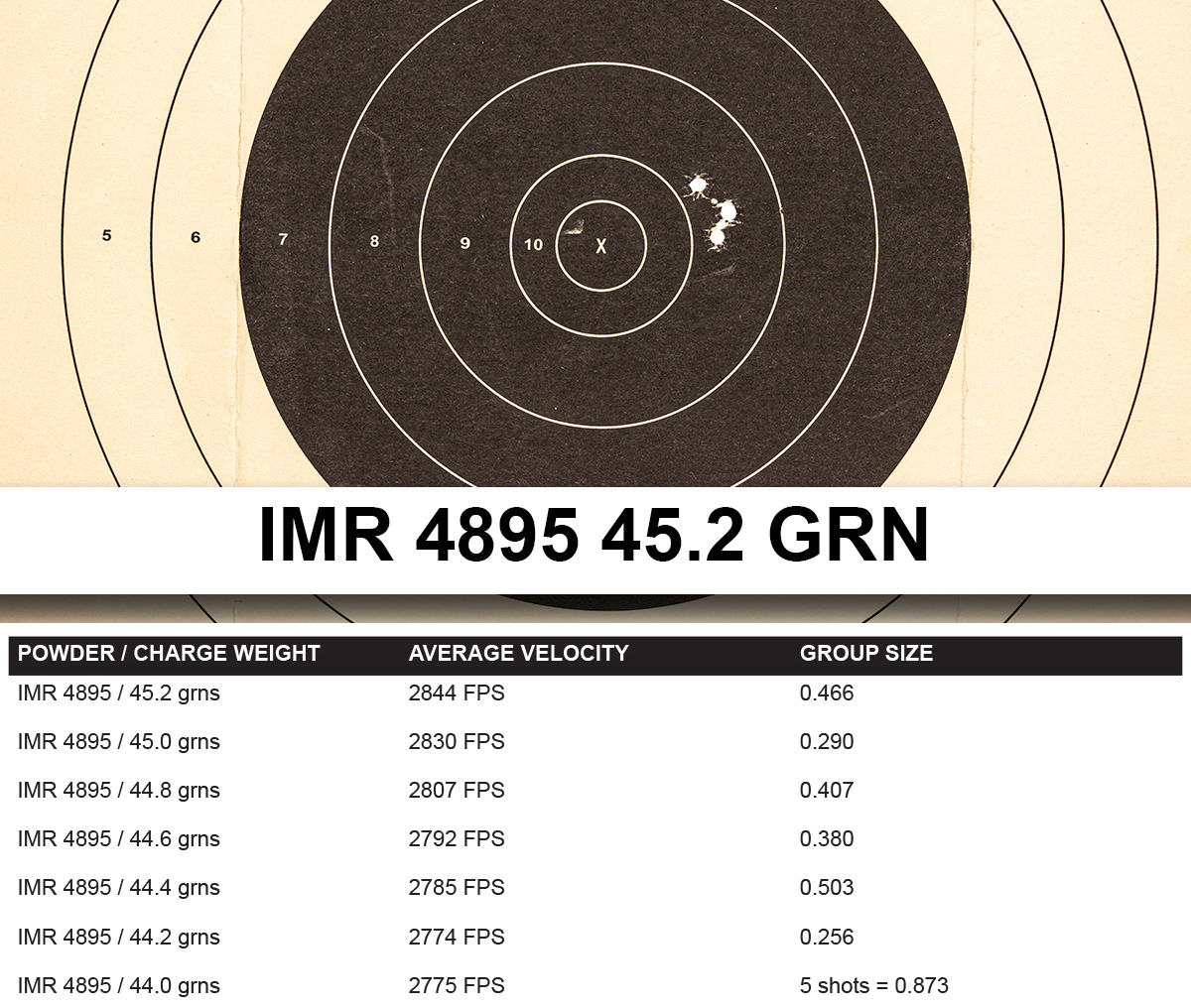

The 45.2-grain load did not show any signs of excessive chamber pressure; however, our test will conclude here as we have safely achieved our target velocity.

Look closely at the six targets produced during the pressure test. Add in the IMR 4895 target with its five-shot group from the powder burn rate test for a total of seven different shot groups all using the same powder. These seven different shot groups span 1.2 grains of powder charge weight in .2-grain increments. Nevertheless, group size, shape, and point-of-impact on target are very similar. Now, compare this with the four targets produced during the burn rate test. The group size, shape, and point-of-impact on the target were all different. While powder charge weight is important, it is my opinion that when it comes to accuracy, getting the powder burn rate correct is of greater importance.

As stated earlier in this series, we are developing a reload using the Hornady .30-cal. 150-gr. Spitzer Interlock bullet to duplicate the Hornady American Whitetail factory load. The published velocity on the American Whitetail load is 2820 fps. When we tested this ammo, we chronographed a 20-shot string with an average velocity of 2842 fps. Our IMR 4895 load, using 45.2 grains, produced an average velocity of 2844 fps, with the 45.0-grain load producing 2830 fps. We must consider that our handload velocities are only from a three-shot average; therefore, they cannot be fully trusted. For our purposes here, the goal is to be as close as possible to Hornady’s 20-shot average of 2842 fps without going over. Of course, this indicates the 45.2-grian load, with its average velocity of 2844 fps, to be the easy choice (even though it’s over by a mere 2 fps). My best guess is that the average velocity over a twenty-shot string will be even higher. It is for this reason that I have decided to pursue the 45.0-grain load for further testing.

We will continue with Part 12 of this series with the final testing of our reloads and see how they compare to the factory Hornady load.

- Shoot ON Reloading Series Pt. 1

- Shoot ON Reloading Series Pt. 2

- Shoot ON Reloading Series Pt. 3

- Shoot ON Reloading Series Pt. 4

- Shoot ON Reloading Series Pt. 5

- Shoot ON Reloading Series Pt. 6

- Shoot ON Reloading Series Pt. 7

- Shoot ON Reloading Series Pt. 8

- Shoot ON Reloading Series Pt. 9

- Shoot ON Reloading Series Pt. 10