Don’t blame your gun, scope, or ammo for poor accuracy just yet. Your problem may be none of the above if your rifling twist rate and bullets aren’t compatible. Here’s what you need to know…

by Lou Patrick

In the early 1970s, my father would occasionally take me with him to the local gun store to pick up a few items that he had needed in preparation for hunting season. I can’t remember how old I was, but my father had started teaching me how to shoot from a very young age. It began with my first Daisy BB gun, and I wasn’t strong enough to work the lever to cock it, but Dad had me on target, as I could routinely hit what I was aiming at. With a big smile on his face, he would work the lever for me after each shot.

By the time he and I are in this gun store, I’m probably about eight years old. I can remember from that time all through my teen years and into the early 1980s that, as hunting season approached, the amount of ammunition on the store shelf increased.

I know…the same thing will occur this hunting season, right?

Well, yes, but not so fast.

Back then, at least in my area, while there was a lot of ammunition on the shelves, the selection was quite small, meaning the number manufacturers and bullet weights available. You could buy all the ammo that you could carry, as long as it was made by Remington, Winchester, or Federal. I don’t remember seeing much of anything else back then. We now have so many different companies manufacturing ammunition that I’m not even going to attempt to list them all. Along with the increase in the number of ammunition manufacturers, we have also experienced a great increase in the different types and weights of bullets available for each caliber.

While all this “ammunition innovation” is of a great benefit to the shooting public, it has also served to make ammunition selection a little more confusing today than it was in years gone by. This is especially true for someone purchasing their first rifle. Once the new rifle purchase is made, the next purchase is likely to be ammunition. But how do you choose from the seemingly endless list of ammunition suitable for use? Rather than making a quick decision, it’s best to do a little planning prior to the ammunition purchase.

Picking the Right Ammo for the Job

With more ammunition available, we need more information to distinguish one product from another. Fortunately, ammo manufacturers have responded.

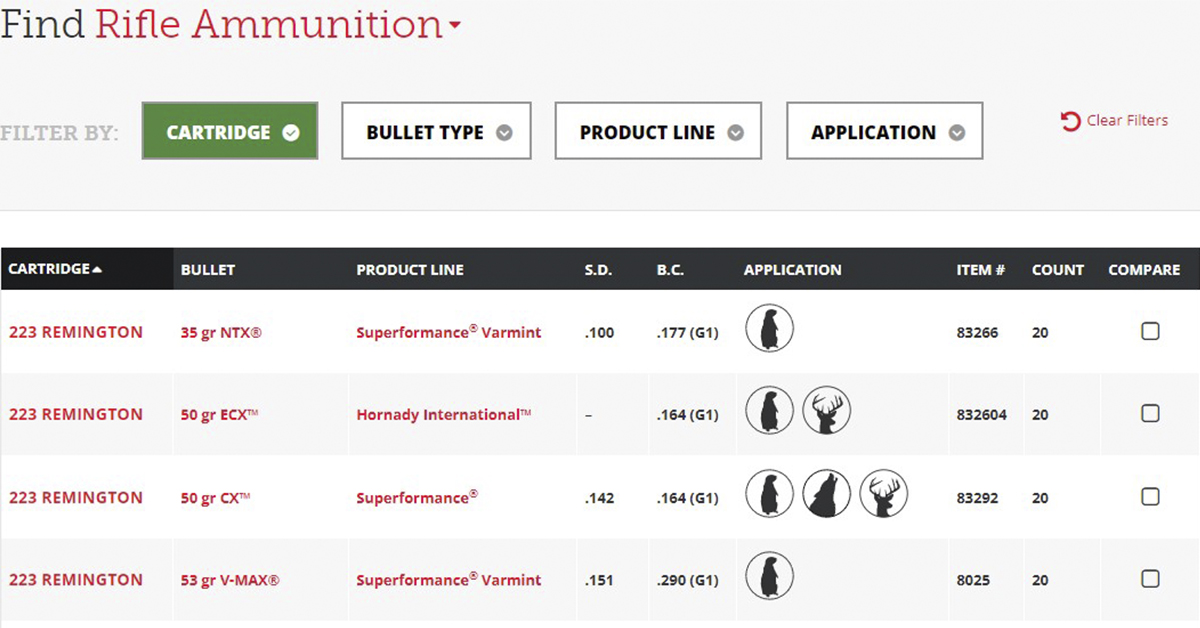

Using the Hornady website as an example, begin by selecting the cartridge. In this case, it is the .223 Remington. Once the selection is made, all the various types of .223 Remington manufactured by Hornady appear. This screen capture, of course, doesn’t include them all. Looking at the left side of the list, we see the cartridge designation of .223 Remington, next the different types and weights of bullets Hornady loads for this cartridge, the sectional density (S.D.), ballistic coefficient (B.C.), and finally the suggested application. Once you match the cartridge designation with that of the chamber, the primary concern now becomes that of bullet weight and bullet construction. Both factors are driven by the intended application of the ammunition.

Clicking on the application box allows you to further filter the search by application. Once you click on this box, you are essentially getting Hornady’s recommendation on bullet weight and construction needed for that application.

While the Hornady ammunition website is packed full of useful tools to guide you in selecting the proper ammunition for a particular application, there’s a little more that we need to know before we make our .223 Remington ammunition purchase.

The Importance of Rifling Twist Rate

Prior to deciding what ammunition to purchase, you should know your rifling twist rate. The twist rate of the rifling is expressed as a ratio, such as 1:7. The “1” represents one complete turn of the rifling. The second number, “7” in this example, represents the distance in inches required for the rifling to make one complete turn. Thus, a barrel with a 1:7 rate of twist will have rifling that makes one complete turn every 7 inches of barrel length. It is the rifling that causes the bullet to spin as it passes down the barrel, allowing the bullet to continue to spin as it exits the barrel and travel along its path to the intended target.

The importance of the spinning bullet to accuracy cannot be overstated; however, all that is required is that the bullet is spinning fast enough to remain stable in flight. Before selecting ammunition for your rifle, you should know your barrel’s rifling twist rate. With this knowledge, you can more effectively choose the bullet of the proper construction while staying within the bullet weight range that your barrel can effectively stabilize.

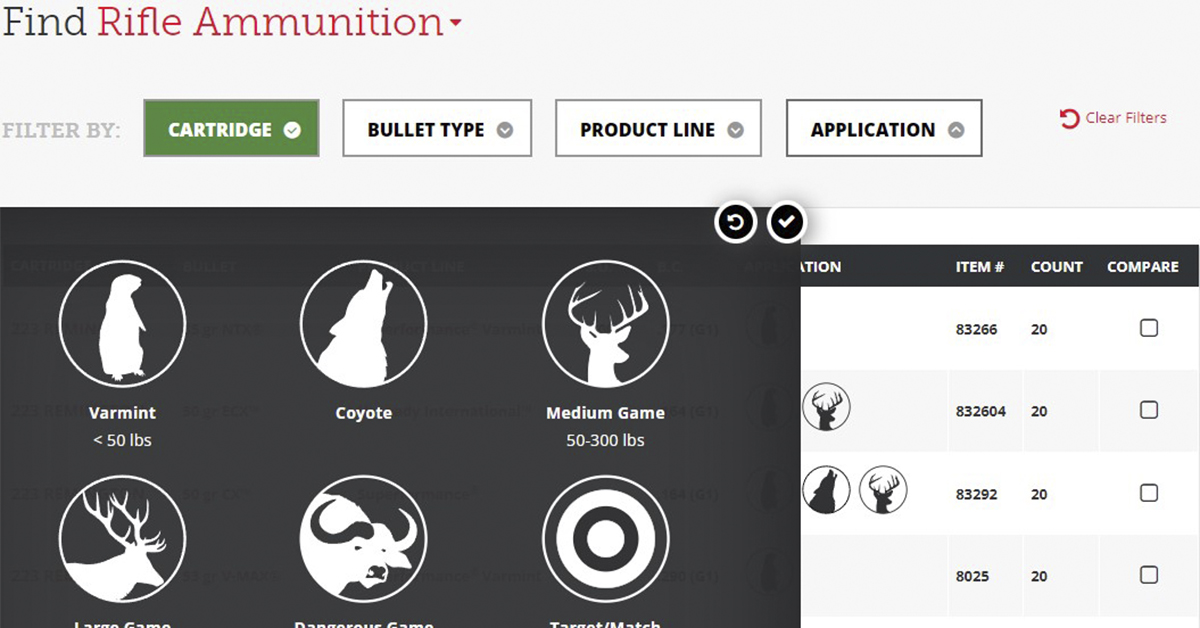

Bullet spin, or rotational speed, is dependent upon two factors: twist rate of the rifling and velocity. The rifling rate of twist is fixed and cannot be changed; however, velocity can be varied. It is important to keep this in mind as the above twist rate chart is applicable (as most are) only to bullets that will be fired at super-sonic velocities. As I mentioned in the beginning of this article, things have changed over the years. I certainly don’t remember seeing sub-sonic .223 Remington ammunition on store shelves in the 1970s, but it’s readily available today. If you plan on shooting subsonic ammunition and hitting what you’re shooting at, you’re going to need a barrel with a fast enough twist rate to make up for the loss of velocity found in subsonic ammunition.

Looking at the twist rate chart above and at the far-left column, the .223 Remington cartridge uses a .224 diameter bullet. This column could just as easily have been labeled .22 caliber, as caliber is reference to diameter. The center column provides the twist rate, the far-right column lists the bullet weight range that can be stabilized by that particular twist rate.

Twist rate charts tend to speak in terms of bullet weight, when, actually, bullet stability or instability is related to bullet length. The longer the bullet is the faster it must be spun in order to remain stable. We speak in terms of bullet weight as a matter of convenience. We can do this accurately because the bullet’s diameter is fixed within a given caliber. When staying within a given caliber, as bullet weight goes up, bullet length increases accordingly.

According to the above chart, a .224 diameter bullet with a weight range from 68-80 grains can be properly stabilized by a barrel with a 1:7 rate of twist. This is also the fastest rate of twist listed on this chart. It’s important to know that the 1:7 twist rate can also stabilize the lighter (shorter) bullets that are listed with the 1:12 and 1:14 twist rates. These lighter bullets, when fired out of the 1:7 barrel, will be stable; however, they will be spinning much faster than what is required for stable flight. This could have a small negative impact on accuracy. The opposite, though, is not true. While a faster twist rate can stabilize a lighter bullet, once the maximum weight (length) is reached, it can’t go any heavier. For example, a 1:14 twist barrel will not stabilize a bullet heavier (longer) than 55 grains.

Hornady has an excellent podcast discussing rifling twist rate.

Identifying twist rate is usually a simple matter with AR15s since most seem to be plainly marked from the manufacturer. The 1/7 on this AR’s barrel is located just behind the flash suppressor and indicates the rifling twist rate of this barrel. Not all ARs are marked with the twist rate because it’s not a requirement of the BATFE, although in my experience, it appears that most are. Unfortunately, when it comes to bolt action rifles, they are rarely marked, if ever. The 5.56 NATO designation on this barrel indicates that it is chambered for the 5.56 NATO cartridge. While it is considered safe to fire .223 Remington ammunition in this chamber, the two are NOT completely interchangeable because 5.56 NATO ammunition SHOULD NOT be used in a rifle chambered for the .223 Remington cartridge. The best advice that can be given when it comes to ammunition selection is to use only ammunition that matches the chamber designation of the firearm. Additional information for selecting ammunition for your AR-15 can be found here.

Pictured are the barrel markings found on a Remington 700. These proof marks are located on the right side of the barrel just forward of the receiver. While these proof marks are important to the manufacturer as a means of maintaining quality control, they are of no real use to the consumer.

Looking at the opposite side of the barrel, we see that it is stamped with a capitol O and M. This is Remington’s way of marking the month and year of manufacturing. This code, which has changed somewhat over the years, combined with the C prefix of the serial number, indicates that this rifle was produced in July of 1992.

Staying on the left side of the barrel and moving forward towards the muzzle, we see the chamber designation of .223 Remington stamped on the barrel. Along with the chamber designation is a brief warning statement and the location of manufacture. The barrel simply is not marked as to its rate of twist, which is common among bolt-action rifle manufacturers.

The rifle we are using in this example is a Remington Model 700 Varmint synthetic. The Remington action, with its heavy barrel contour combined with the aluminum V-block bedding system of the HS precision composite stock, proved to be a very accurate combination right out of the box. This rifle was an instant success upon its release and most likely more than one of our readers owns one. When properly maintained, this rifle will provide years of good service, and that’s the key word — years. Looking at the barrel markings of this particular rifle, we learned that not only is it chambered in .223 Remington, but we also learned that it was manufactured in July of 1992. This is important to us today because rifle manufacturers will typically rifle their barrels with a twist rate that will stabilize the heaviest bullet that is currently being loaded for use in a particular cartridge. Remember, if the rifling twist rate is such that it can stabilize the heaviest bullet, it will also stabilize the lighter bullets.

The Remington Arms website shows that current production Model 700s chambered for the .223 Remington cartridge have a barrel with a 1:8 twist rate. The heaviest bullet currently being offered by Remington loaded for the .223 Remington cartridge is 77 grains. But was this the case in 1992 when our Remington 700 Varmint synthetic was manufactured?

Measuring the rifling twist rate of your rifle’s barrel is a rather simple task that only takes a few minutes. All that’s needed is a cleaning rod, bore guide, oil, patch and jag, masking tape, and an ink pen. Before working on any firearm, ensure that it is unloaded and that there is no ammunition present in the work area.

Remove the bolt and install the bore guide. The bore guide isn’t absolutely necessary for this task, although its use does provide an easier surface of reference for which to mark the rod. It also guides the rod straight into the bore, preventing the cleaning rod from contacting the rifling and possibly damaging it.

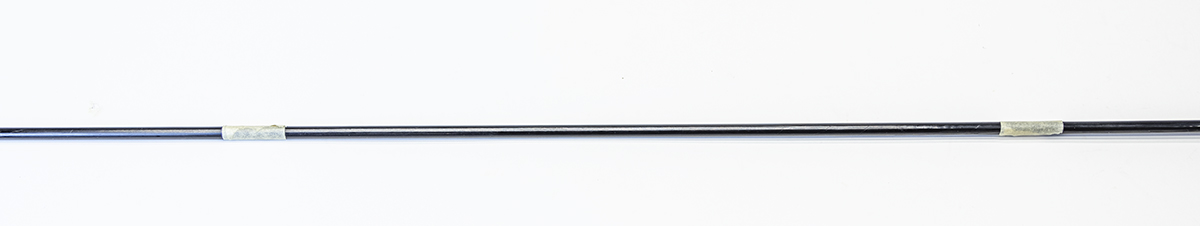

Any cleaning rod will work for this project provided that it is sized appropriately for your rifle and will allow the rod to turn easily within the handle. Cleaning rods such as the Dewey coated cleaning rod pictured here are perfect for this project.

Place a piece of masking tape around the cleaning rod as close to the handle as possible. Ensure that it does not interfere with the rotation of the cleaning rod.

Place a piece of masking tape on the forward end of the handle and draw a reference line on each piece of tape as pictured.

Install the cleaning jag on the rod and place a lightly oiled patch on the jag. The cleaning jag and patch type are not important. What matters for this project is that the patch and jag combination fit tight in the bore. The patch and jag must fit tight enough within the bore to provide for accurate/reliable rotation of the cleaning rod, yet not so tight as to be forced down the bore.

Insert the patch and jag into the bore guide, slowly pushing the rod forward until you feel the patch make contact with the bore.

Once you feel contact with the bore, slowly push the rod forward until the rod begins to rotate. Once the rod rotates about a quarter of a turn, stop. This is enough rotation to ensure that the patch has engaged the rifling. Don’t be concerned if you push the rod a little further past the quarter turn position. You don’t have to be precise with this step of the process. If your barrel is long enough, you can go a full rotation. The focus here is to ensure that the patch is fully engaged in the rifling, the rod rotates freely, and that it will complete a full rotation with the patch remaining in the bore.

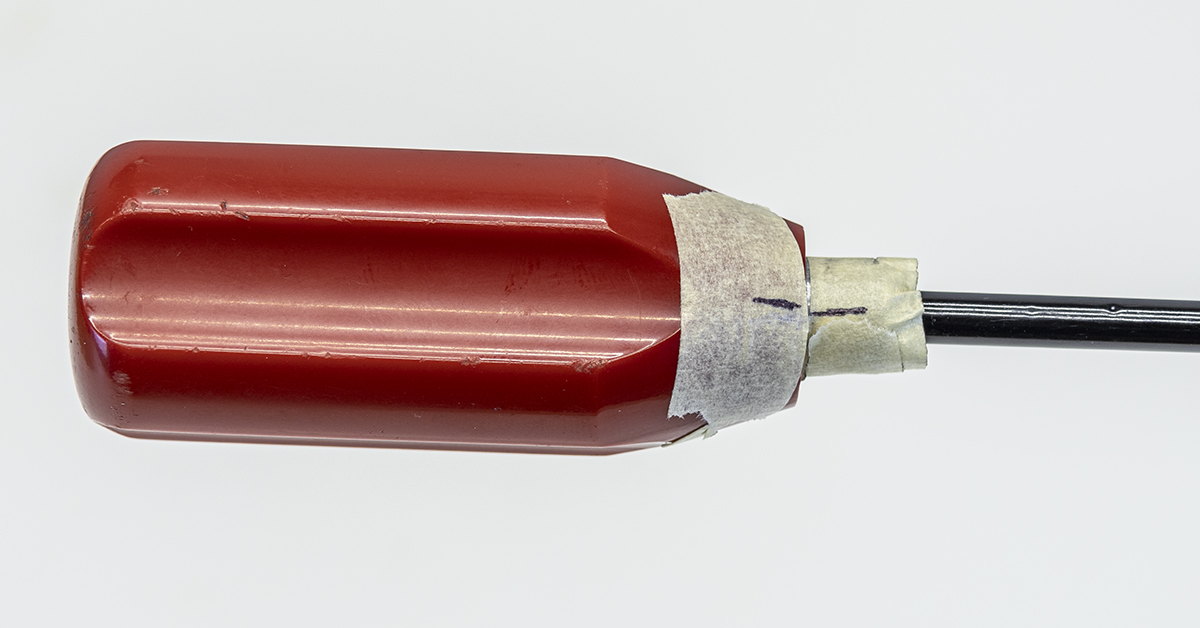

With the front edge of the masking tape contacting the rear edge of the bore guide, wrap the cleaning rod with one layer of masking tape as pictured. Depending on what caliber of rifle you are using and the cleaning rod being used, the tape may interfere with rod rotation. It is important to wrap the rod once and that the tape lies smoothly around the rod.

While maintaining the rod in its current position, rotate the handle until the reference lines are in alignment. Now, slowly push the rod forward. The cleaning rod will rotate. Once the cleaning rod has made one complete rotation and the lines are once again in alignment, stop.

As done previously, wrap one layer of masking tape around the cleaning rod with its forward edge in contact with the rear edge of the bore guide. Next, slowly push the cleaning rod forward.

Once the patch exits the muzzle, stop and remove the patch. Remove the cleaning rod and bore guide, reinstall the bolt, and set the rifle aside.

Your cleaning rod will now look like this. As pictured, the cleaning rod handle is to the right, meaning that the direction the rod traveled through the bore is from right to left. It is the left edge of the tape that was placed in contact with the bore in the previous steps.

Measure the distance from the forward (left) edge of the first piece of tape placed on the rod to the forward (left) edge of the second piece of tape placed on the rod. This distance represents how far the patch traveled through the bore until one complete rotation of the rifling occurred. We now know that our Varmint synthetic from 1992 has one rotation in 12 inches, or a 1:12 twist rate. Looking at the previous twist rate chart, you can see that the heaviest .22 caliber bullet that this twist rate can stabilize is 60 grains.

Hornady’s website shows that the company is loading a 75-grain match bullet for this cartridge. If you were unaware of your twist rate and were simply standing in the store looking at the ammunition shelf, you very well may think this Hornady 75-grain match load should produce some really small groups out of your heavy barrel 700. In reality, it doesn’t have a chance. You would most likely find yourself at the range disgusted and wondering what is wrong. Rather, nothing is wrong at all. This rifle and ammunition combination just isn’t going to work very well.

Out of curiosity, I called Remington and asked if they could tell me the weight of the heaviest bullet that was available in the Remington ammunition line-up for the .223 Remington cartridge in 1992. I thought for sure I was about to get laughed at (it was only 32 years ago, after all). Amazingly, I got a quick answer.

“Sir, 60-grain was the heaviest bullet that we loaded for the .223 Remington cartridge back then.” Wow! Of course, Remington 700s currently produced for this cartridge have a faster 1:8 twist rate, which is sufficient to stabilize the heavier bullets that are available today.

Something else that has changed over the years is bullet construction. We’re not just shooting copper jacketed lead anymore. Remember that bullet stability is related to twist rate, velocity, and bullet length. While twist rate charts such as the one found in this article do serve as an aid in bullet selection, do not consider them to be the “be all, end all” in answering that question. Keep in mind that sub-sonic ammo will have different requirements. Also, regardless of velocity, when lead is substituted for some other material, the bullet will most likely be longer than a lead core bullet of the same weight. Is this added length sufficient enough to be of concern with your twist rate? If in doubt, the best source to answer these questions is the manufacturer, as they have fired countless rounds in testing prior to the ammunition reaching the store shelves.

Once you know the operational parameters of your firearm and work within them, and then combine this with the information and tools that are available today, selecting the proper ammunition for your intended purpose is a simple matter. Once you put all this together, accuracy is sure to follow. All that is needed from there is minor scope adjustments to move the shot group to the desired location on target.