Here’s a tip from the benchrest pros that can help tighten your groups for the price of a diner lunch

by Lou Patrick

What if I told you there was a simple technique that has the potential to deliver smaller groups from your rifle for little more than chump change?

“Crazy,” you say?

Not at all. In fact, this technique has been around for quite some time courtesy of those hyper-technical, nuance-driven shooters from the benchrest community. It all boils down to having a clean barrel.

“But I clean my barrels to within an inch of their lives,” you say.

Well, if you only clean your barrels with a bore brush and popular commercial solvents, the truth is there remains a lot of fouling in those barrels—particularly deep in the sharp land/groove corners—that, if not removed, will degrade your rifle’s accuracy over time.

Have you ever shot a rifle for several years and noticed that it just doesn’t hold the tight groups you remember from earlier in its life? It could be a result of hundreds or thousands of rounds shot and copper/carbon buildup in the rifling that is the problem.

Fortunately, there is a simple, low-cost solution to breathe new life into a well-seasoned barrel that has the potential to not only restore accuracy in older barrels but even to improve performance in new rifles. This little trick comes to us from the benchrest crowd and involves using JB Bore Cleaning Compound and Kroil.

Skeptical? Check this out…

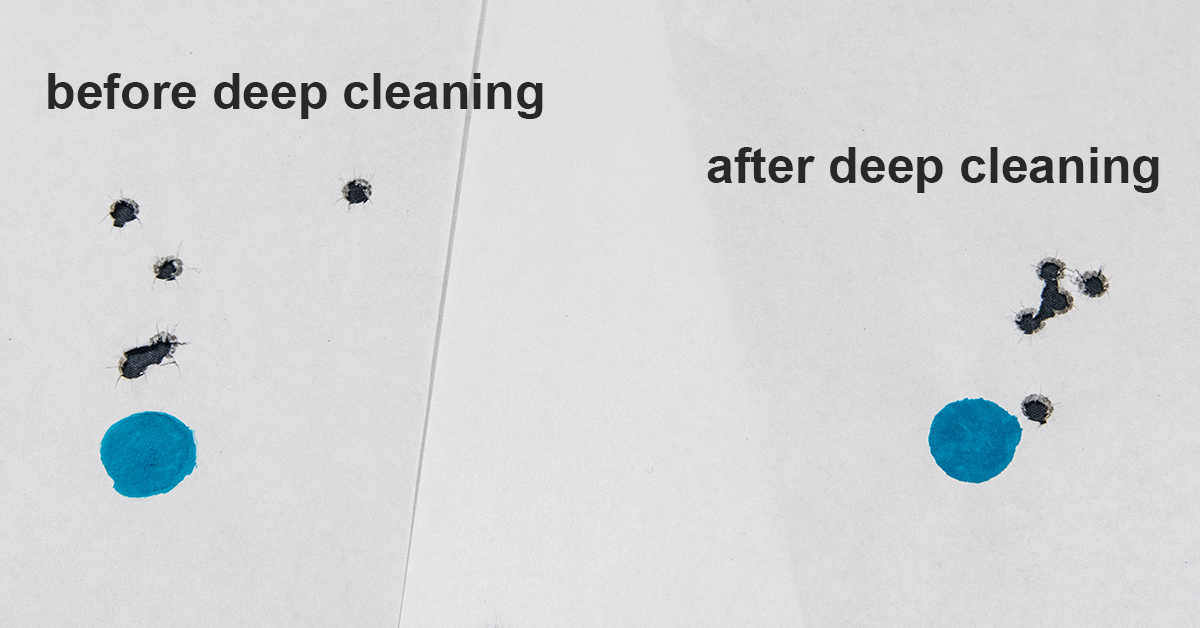

A friend came to me recently looking to boost the accuracy of his decade old Remington 700 chambered in .264 Win Mag. He had already purchased a new synthetic Bell & Carlson stock, which we pillar-bedded. This helped, however, Aaron was still not satisfied. I asked if he had ever cleaned the barrel using the JB and Kroil treatment. He had not. I recommended we give it a try. As you can see from the above results, a barrel deep-cleaning did the trick. Shooting the same load, the JB and Kroil technique made a significant improvement in his rifle’s accuracy—all for the cost of lunch and a bit of elbow grease. Brownell’s sells a 1/4-ounce of JB Bore Cleaning Compound for $4.99 and an 8-ounce can of Kroil for $13.79 for a total of $18.78. Add in a few cotton flannel cleaning patches and you’re set.

JB Bore Cleaning Compound is a mild abrasive paste—so mild that it will not harm the bore, yet it is aggressive enough to remove the most stubborn fouling. Kroil is a penetrating oil that is known as the “oil that creeps.” This oil will, indeed, creep into and under the most tenacious fouling like no other penetrating oil. When used in combination, these two products are a power-cleaning duo.

JB and Kroil do not need to be used every cleaning session. Some shooters use them every couple hundred rounds to keep fouling build-up to a minimum. Between these deep-cleaning sessions, just follow standard cleaning procedures with a bore brush, patches, and solvent.

While the use of JB and Kroil is not harmful to the bore, I find that its use every couple hundred rounds may be a bit excessive in some cases. For hunting and duty rifles I recommend using JB and Kroil:

- after the purchase of a used rifle (prior to the first range trip)

- when a rifle is not performing as it should (this treatment may restore lost accuracy or improve accuracy of new firearms)

JB and Kroil not only removes difficult fouling, the mildly abrasive quality of the paste aids in removing tooling marks from the manufacturing process. Often, these tooling marks are in the bore perpendicular to bullet travel and abrade the bullet during its travel down the bore. Eliminating or minimizing these tooling marks can have a positive affect on accuracy. The resulting smoother bore can also minimize fouling buildup, making it easier to clean the bore with a standard brush and solvent.

While individual results cannot be guaranteed, I have had positive results in the past and, considering what’s involved and the low cost, it’s certainly worth a try.

The JB and Kroil Process

Begin by reviewing the manufacturer’s instructions concerning JB Bore Cleaning Compound to become familiar with the product. Next, clean your bore using standard cleaning procedures (solvent, wire brush, jag, and patches).

Place electrical tape over the muzzle. I place one piece horizontal and one piece vertical to the bore. This serves as a stop to prevent the cleaning rod from exiting the bore.

Secure MTM’s Patch Catcher to the end of the barrel to capture any oil that may seep out during the soaking process.

Insert a bore guide into the receiver to help guide the oil into the bore and to support the cleaning rod.

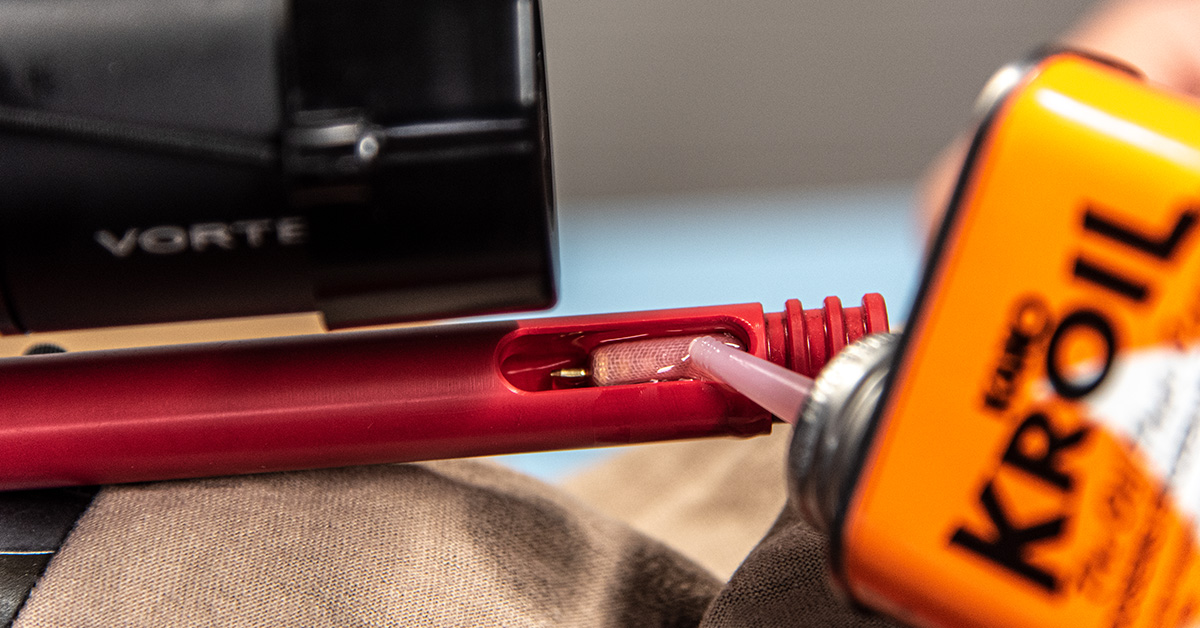

Flood the bore with Kroil.

Place a clean patch onto the jag and saturate the patch with Kroil. Push the patch down the bore, stopping once the jag tip touches the tape on the muzzle (don’t push through the tape).

With the cleaning jag touching the tape on the muzzle, wrap a piece of tape on the cleaning rod just behind the bore guide. This will serve as a visual indicator as to where to stop forward travel on subsequent passes down the bore while keeping patch and jag in the bore.

On the return stroke, go slowly and you will feel the patch fitment loosen once it passes into the chamber’s throat. This is where you will stop and change direction. Make a dozen or so complete passes down the bore and then remove the patch and allow the Kroil to soak in the barrel for 24 hours. The oil that creeps needs time to creep!

After 24 hours have passed, remove the tape from the muzzle. Work JB Bore Cleaning Compound into a clean cotton flannel patch.

Pierce the center of the patch with the cleaning jag and work the JB along the entire length of the bore, paying special attention to the area just ahead of the throat. It doesn’t hurt to short-stroke the first 10 inches or so of the barrel just ahead of the throat.

The cleaning rod is marked to indicate maximum forward travel. After making a dozen or so passes along the bore, stop and remove the cleaning rod.

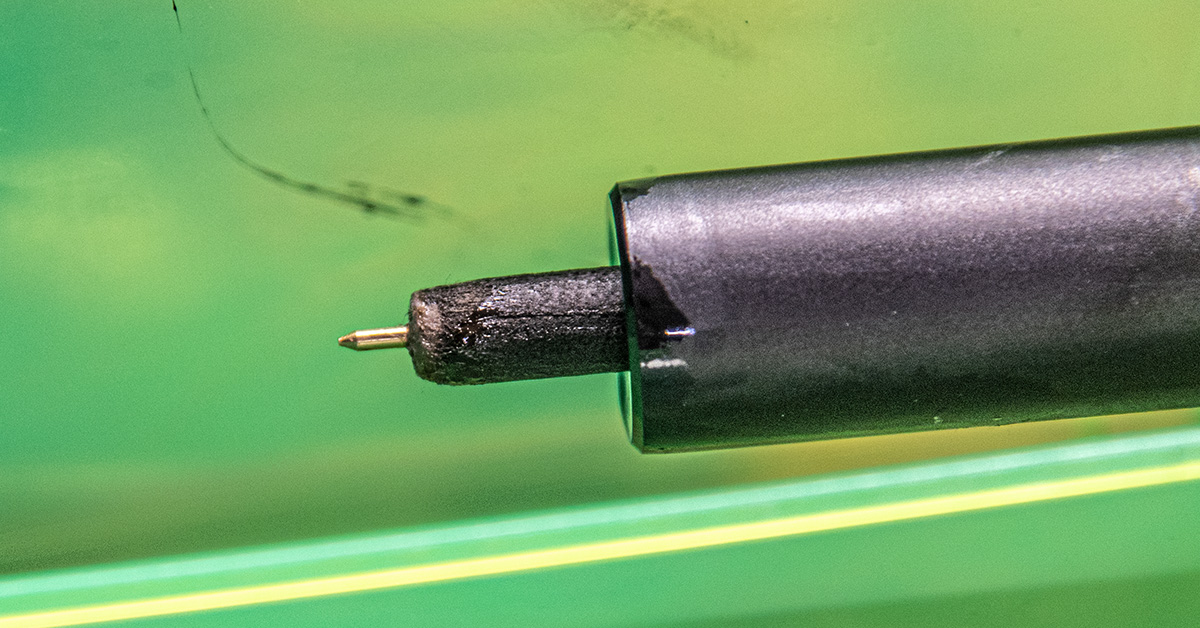

With the tape removed from the muzzle, you can see what the first run of JB and Kroil released from this previously “clean” .308 Win bore in a rifle that has had under 100 rounds fired through it—proof that standard brush-and-solvent cleaning protocols can never remove all fouling from a bore.

With the first scrubbing complete, remove the patch and wipe down the cleaning rod and jag to remove all oil and compound residue.

Saturate a fresh patch with Kroil and remove any remaining residue from the bore. As you can see from this patch, there is a good bit of residue to be removed.

For a proper deep cleaning, you should repeat this process two more times, minus the 24-hour Kroil soaking period. Once the JB and Kroil process is complete, thoroughly remove all traces of the JB and Kroil process.

Here is the batch of patches from the final cleaning stage of this .308. From left to right: residue removal swab, dry swab, Kroil swab, lubricating oil swab, dry swab. This barrel is officially CLEAN! Once clean, run a lightly oiled patch through the barrel for rust protection and the rifle is ready for the gun case or the next trip to the range.