A decade in, Dead Air Silencers unveils the next generation in the Sandman suppressor series. Enter Sandman X.

by Rob Reaser

Marking its 10-year anniversary, Dead Air Silencers isn’t what you would consider to be a young company. Neither is it counted among the many upstart enterprises that are steadily filling the suppressor marketplace. But in its decade of operation, Dead Air Silencers has earned a mighty reputation for building reliable, hard-use suppressors for a broad range of applications.

Leading that noteworthy pack is the Sandman series — the line that launched the company. Specifically, we’re talking about the Sandman S. This .30-caliber suppressor that has earned the favor of defense professionals, hunters, competitors, and recreational shooters across the country.

Leveraging Technology

This year, in recognition of the Sandman’s 10 years, Dead Air Silencers introduces the Sandman X. This second-generation model in the Sandman series represents not just an updated version of the original but a start-from-scratch redesign with the lofty goal of improving function in all performance points. To do this, Dead Air engineers leveraged new materials and new manufacturing techniques to deliver a suppressor that holds to the original Sandman’s tough, hard-use attributes while improving sound performance, enhancing flash suppression, and minimizing backpressure. What’s more, Dead Air pulled this off while maintaining a relatively compact and lightweight design.

The core difference between the Sandman X and its predecessor lies in the material used and the construction techniques. Whereas the original Sandman S featured a welded construction, the Sandman X is built through additive construction. In other words, it is 3D printed. The material used for construction is Haynes 282.

According to the source company, Haynes International, Haynes 282, “is a wrought, gamma-prime strengthened superalloy developed for high temperature structural applications, especially those in aero and industrial gas turbine engines. It possesses a unique combination of creep strength, thermal stability, weldability, and fabricability not found in currently available commercial alloys.” Haynes International lists such applications as components used in high-temperature environments like the turbine, exhaust, and combustor sections of gas turbines as well as nozzle components. This is unquestionably a suitably strong and temperature stable material for a suppressor that is full-auto rated and not kneecapped with barrel length restrictions.

Haynes 282 is a material that offers exceptionally high heat and pressure tolerances. Dead Air began using this material on their Lazarus 6 suppressor. They were so impressed with the results that they decided to apply it to the Sandman X.

One of the advantages of additive manufacturing (or 3D printing) is that it allows for complex internal designs that aren’t achievable with conventional machining processes. One of the things Dead Air hails as a benefit to this manufacturing process is better alignment and concentricity to the bore axis. Dead Air also claims that this process makes for a stronger can because it is monolithic rather than welded together.

Triskelion Gas Management

The new Sandman X taps Dead Air’s Triskelion gas management system instead of a traditional baffle system. It is a design also used on the company’s Lazarus 6 and Mojave 9 suppressors. The Triskelion system directs propellant gasses out the front of the suppressor. This accounts for the Sandman X’s reduced backpressure and lower tone versus suppressors with conventional baffle systems.

Broad Cartridge Compatibility

The Sandman X continues the .30-caliber bore theme and is rated for cartridges up to .300 Remington Ultra Mag. It also works with smaller cartridges down to the always popular .223 Rem./.5.56 NATO. That’s a boon for AR fans who like to switch it up between their AR-15 in .223/5.56, .300 BLK, or the mighty AR-10.

Mounting Options

When you purchase a Sandman X suppressor, you get everything in the box necessary to mount onto a 5/8-24 threaded barrel and hit the range. This includes the suppressor, adapter (Dead Air KeyMo or Xeno), muzzle device (compatible with the adapter of choice), shims, and two TL wrenches.

The suppressor is optioned with one of two Dead Air mounting systems — KeyMo or Xeno. Check out these links for a deeper dive into each system. Because the Sandman X features the industry standard 1 3/8×24 thread, you can use the suppressor with a wide range of HUB-compatible adapters and muzzle devices. This includes, of course, Dead Air’s KeyMo and Xeno systems.

That is another change between the Sandman S and the new Sandman X. The former uses only the KeyMo mounting system — a hard-duty-use, quick-detach mount that won’t come loose and ensures precision alignment. The Xeno system is a more compact and lightweight adapter system, offering exceptional lockup and high precision courtesy of its tapered mount design.

What’s cool about the Xeno mount is that there is no break-in process as there is with the KeyMo system. It is a lighter weight, more compact mounting system ideal for precision shooting, where high volume and hard use are not priority considerations. If the latter is your bag, go with the KeyMo option.

Mounting Explained

For our Sandman X, we went with the Xeno mounting system since it would see the most use on a home defense .300 BLK SBR and a precision AR-15 built for varmint hunting. Understanding that the combination of suppressor mounting systems, adapters, and muzzle device compatibility can be a bit confusing for those considering a suppressor for the first time, we’re going to walk you through the process of installing the Sandman X onto an AR platform. In this case, it is going onto a .300 BLK, which features a 5/8-24 thread at the muzzle. A .22-caliber AR-15 barrel will come with 1/2-28 thread. Dead Air sells muzzle devices with multiple thread pitches. It is easy to find the muzzle device you want that is compatible with either the KeyMo or Xeno mounts.

Start by removing the existing muzzle device from the cleared and rendered-safe gun.

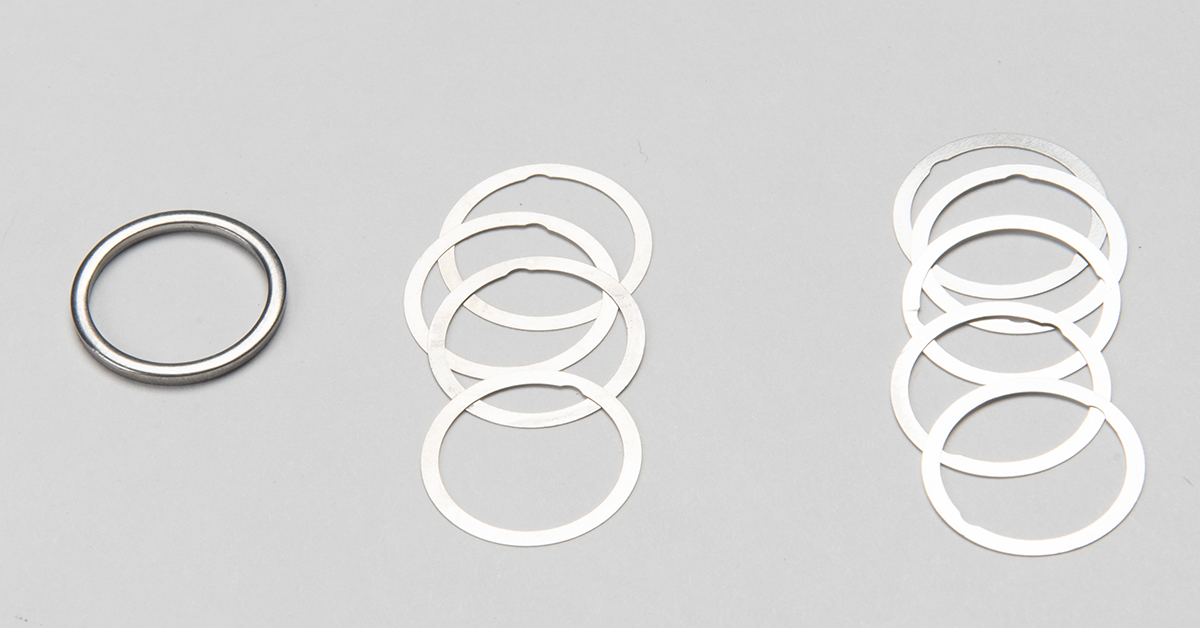

AR-platform rifles typically use a crush washer behind the flash hider or brake. Remove this and throw it away. Crush washers are not used in conjunction with suppressors because they could lead to improper bore alignment. If required for alignment purposes, spacers or “peal washers” are used instead.

Dead Air does not recommend the use of lubrication on any threads. This includes the muzzle device-to-barrel threads. Clean the threads of any grease or oil with denatured alcohol.

Do the same for the muzzle device threads.

Wipe the muzzle device threads with a saturated swab to better clean out the threads.

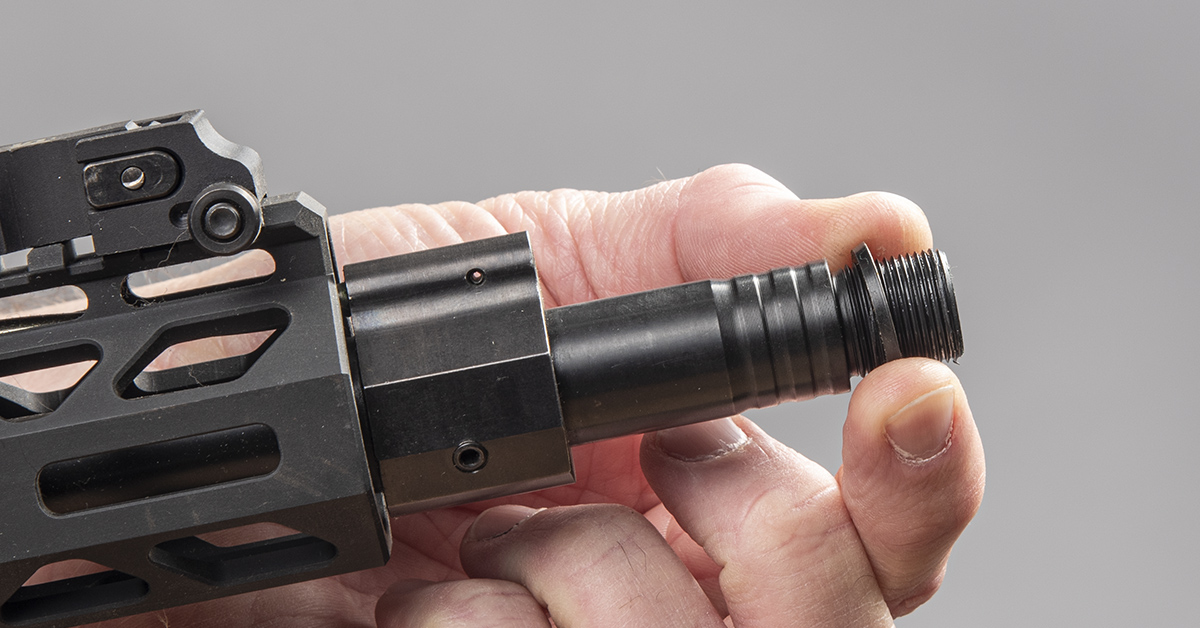

Xeno muzzle devices, such as this three-prong flash hider, have an exterior thread that allows suppressors with the Xeno adapter to screw onto it. This means you can take the suppressor off the gun while the muzzle device stays in place. If you have a muzzle device that requires timing (screwed onto the barrel in a precise orientation), then it will be necessary to shim it into final position. We wanted to time the three-prong Xeno flash hider with one prong at the 12 o’clock position to minimize any muzzle flash interfering with the sight picture in a dark environment. Should you need to orient the muzzle device, begin by screwing the device onto the barrel and guesstimating how many shims you need to achieve timing at the proper torque setting.

Each Sandman X comes with a 5/8-inch shim kit. You’ll need 1/2-inch shims if you are installing a 1/2-28 muzzle device onto a 1/2-28 barrel).

Timing the muzzle device is something of a trial-and-error process. Use a combination of different shim thicknesses and quantity to achieve the correct muzzle device position.

When the timing is almost there, torque the muzzle device to between 25 and 35 ft/lbs. Do not exceed 35 ft/lbs or you may introduce some accuracy degradation. The goal is to achieve the desired muzzle device position within the 25-35 ft/lbs torque range. This process may require a “lather, rinse, repeat” process until you get it right.

Dead Air supplies two spanner wrenches to assist in installing or removing the adapter from the suppressor. They work (see the owner’s manual), but they require careful alignment and controlled squeezing to prevent slipping off the components.

The better method is to use a 1 1/8-inch socket to remove or tighten the adapter.

With the muzzle device installed on the barrel and the adapter installed in the suppressor, screw the suppressor assembly onto the Xeno muzzle device and tightened down by hand (see the owner’s manual for full details). The suppressor assembly screws on counterclockwise. This is a good feature because whenever you remove it from the barrel you won’t run the risk of loosening the barrel-to-muzzle device connection.

Impressions

Installed and tested on a .300 BLK SBR, the Sandman X offered an exquisite balance in hand. The suppressor and adapter assembly added a mere 14.5 ounces to the end of the barrel. The overall length of 6.4 inches kept the weapon nimble and plenty compact for close-quarter engagement.

We experienced no noticeable backpressure, and the sound signature proved pleasing enough — whether shooting supersonic or subsonic ammo.

If you are banking on an increase (albeit slight) in muzzle velocity or kinetic energy with the addition of this suppressor, don’t. In our tests using the new Fiocchi SBR Enhanced ammo in .300 BLK, those numbers actually dropped a bit for both supersonic (-9.3 fps / -10.02 ft/lbs) and subsonic cartridges (-2.4 fps / -2.4 ft-lbs) per the Garmin Xero C1 Pro chronograph.

We are a ways from a long-term evaluation of the Sandman X, where we will be throwing a heavy dose of 5.56 and .308 rounds through it over the coming months. As first impressions go, though, there’s no doubt that Dead Air has added another sturdy hero to the Sandman suppressor lineup.

Dead Air Sandman X Suppressor Specifications

- Caliber Rating: up to .300 RUM

- Energy Rating: 4200 ft/lbs

- Bore Diameter: .30-caliber

- Length: 6.4 to 6.9 in.

- Width: 1.65 in.

- Weight: 14.5 oz. or 16.8 oz.

- Materials: Haynes 282

- Finish: Black or FDE Cerakote

- Usage: professional-grade heavy-duty

- Barrel Restrictions: none

- Full-Auto Rated: yes

- Warranty: lifetime

- MSRP: $999-$1059