Assuming a quality barreled action in hand, here’s how to turn your factory rifle into a customized wonder in no time flat

by Rob Reaser

I’ve hinted in writings past that I have something of a love-hate relationship with aftermarket firearm components and accessories. Some products are stellar in their design and manufacturing quality. Some actually meet the objective of the genre in that they deliver a genuine improvement or enhanced benefit over the original factory design and function. Too many, though, are merely “solutions” looking for a problem to fix.

Let’s face it…most of the time, the factory gets it right.

While I’ll grant that the quality and precision of many production line rifles are light years ahead of where they were not that long ago, two areas where most can still benefit from the aftermarket touch are the stock and the trigger. That is assuming, of course, that the barreled action is spot-on in terms of its accuracy potential.

The stock and trigger work hand-in-hand to assist a quality barreled action in delivering the kind of point-of-aim/point-of-impact performance that leads to big grins and much boasting.

A stout, well-made stock that fits the shooter is the foundation that holds the barreled action in predictable alignment as the bullet travels down the bore. A high-quality trigger minimizes shooter-induced anomalies that can upset the shot prior to the sear break and before the firing pin strikes the primer. These three systems — a good barreled action, a rigid, high-quality stock, and an ultra-precision trigger — are the essential ingredients for a true “shooter.”

Given that the search for smaller shot groups is the goal of any recreational shooter or hunter, we don’t need a practical excuse to upgrade or customize a rifle. Better fit, enhanced performance, updated aesthetics, or simply the desire to get an old, worn, and seldom-used rifle back in the game is reason enough to embark on the DIY customization journey.

One company that has led the charge in premium, custom wooden stocks since 1981 is Boyds Gunstocks out of Mitchell, South Dakota. For over 40 years, Boyds has offered the solution for shooters looking for improved fit, finish, and function beyond that offered in factory stocks.

I’ve added Boyds stocks to several of my long guns over the years, currently including a custom 10/22 squirrel killer, a Remington .270 that has put many whitetails in the freezer, and my too-much-fun Romanian AKM. As you can tell from the latter, Boyds makes a gun stock for just about any firearm out there.

A couple years ago, my cousin picked up a used Howa 1500 Hogue in .308 Win. for a stellar price. As factory guns go, the Howa 1500 is a reliably solid performer. Initial sight-in a few weeks before our rifle season opener proved this gun had serious potential well beyond the deer woods. So, we mapped out a plan to bring it to the next level. Step one would focus on the foundation.

There are several hallmarks that make a Boyds stock an ideal option for the DIYer, first among them being the inherent rigidity. Polymer stocks typically found on production rifles like the Howa 1500 Hogue will flex under recoil. This can lead to the bore axis shifting position following cartridge ignition. Any shifting of the bore axis prior to the bullet leaving the muzzle means that the point-of-impact will not hold to the point-of-aim.

Boyds crafts their gun stocks from premium laminated hardwood. The laminating process combined with the imbued strength of multi-directional wood laminates makes for a stock that is not only exceptionally strong but one that resists flexing under recoil.

For our project, we selected Boyds’ Agility stock system. As with all Boyds stocks, the Agility begins as a hardwood laminated billet that is machined to a form the company refers to as “a modern version of a traditional gunstock.” As you can see, it is an elegant merging of classic design cues with conventional features for the modern long-range, precision rifle shooter.

The hybrid grip, for example, offers a wrist profile that works with off-hand or field supported shooting positions yet slopes aggressively through a modified grip angle that is conducive to prone shooting.

Furthering the prone shooting mission is the butt hook stock. This offers the shooter a solid non-firing-hand grasp of the stock for enhanced field stability or the ability to “ride the bag” during bench shooting sessions.

Along those same lines, the semi-beavertail forend presents a flat surface that also boosts stability when shooting off a pack or other field support. For off-hand shooting, each side of the forend has a raised profile that works as “reverse finger grooving” to ensure a positive grip for standing and kneeling shots.

Shooter customization is another key element to the Boyds Agility stock. The length-of-pull (LOP) can be adjusted from 12.5-14 inches (standard) or 14.5-15.25 inches (extended) depending on your build selection. By simply pressing the adjustment button, the butt plate can be quickly extended or collapsed. This is a big advantage not only for delivering a proper LOP for the shooter, but it also allows the shooter to change the LOP with clothing requirements. When wearing heavy winter clothing, for instance, the LOP can be shortened to maintain the correct fit.

The Agility comes with an ambidextrous Monte Carlo-style comb profile, which is always welcome. But even with a Monte Carlo comb, not all shooters will experience a perfect cheek weld and eye alignment behind the scope. To solve this and to provide further shooter customization, the Agility boasts an adjustable-height cheek piece. A hex wrench is used to raise or lower the cheek piece via an internal screw-and-pillar system.

As with all Boyds stocks, customization goes beyond the functional. Each stock is custom built to the consumer’s specifications, and the options are many. Boyds offers ten different laser engraving options for the grip and forend along with assorted symbol engravings and text options. Here, you can see the Agility Multi-Point laser pattern in Basketweave texturing.

The same pattern extends along the bottom of the forend. It is a stylish touch that provides real function by augmenting grip and retention.

Black forend tips and grip caps are also options when ordering. While non-functional, they add visual distinction that hearkens to the traditional American rifle stock design.

Color options are also part of the Boyds customizing program. The laminated hardwood is, by itself, stunning in its natural hues, but aesthetics really ramp up when you plug in one of the 14 colors available. This stock color is called Coyote, and the alternating dark and light laminations burst through with the Agility’s highly contoured profile.

Boyds stocks are designed to be an easy swap for the DIY gun enthusiast. That means your barreled action will fit with zero to minimal inletting work required. Unlike conventional custom wood stocks that must be inletted (carved out to accept the barreled action) by a skilled gunsmith, Boyds makes their stocks to be true drop-ins.

The catch is, there always exists the possibility of some fitment variations between your barreled action (due to possible changes in manufacturing over the years) and the model forms used by Boyds to create the inletting. Of all the Boyds stocks I’ve installed, only a couple have required some minor inletting adjustments to accept the barreled action.

Note the aluminum pillars installed in the stock. This, also, is an option you can select during your stock build-out, and one we highly recommend.

Installing the Boyds Agility Stock

Begin by clearing the firearm and removing the bolt assembly.

Support the rifle upside down in a suitable cradle. My favorite for most long gun work is the Gun Vise made by MTM Case-Gard. This vise fully supports the gun and features a lever to clamp the stock in place to prevent the gun from wobbling as you work. This isn’t a super-heavy-duty tool in that it is made from molded plastic, but it does the job and is easily moved around the shop and stows conveniently when not in use.

Support the barreled action with one hand and remove the action screws.

Lift out the bottom metal from the stock.

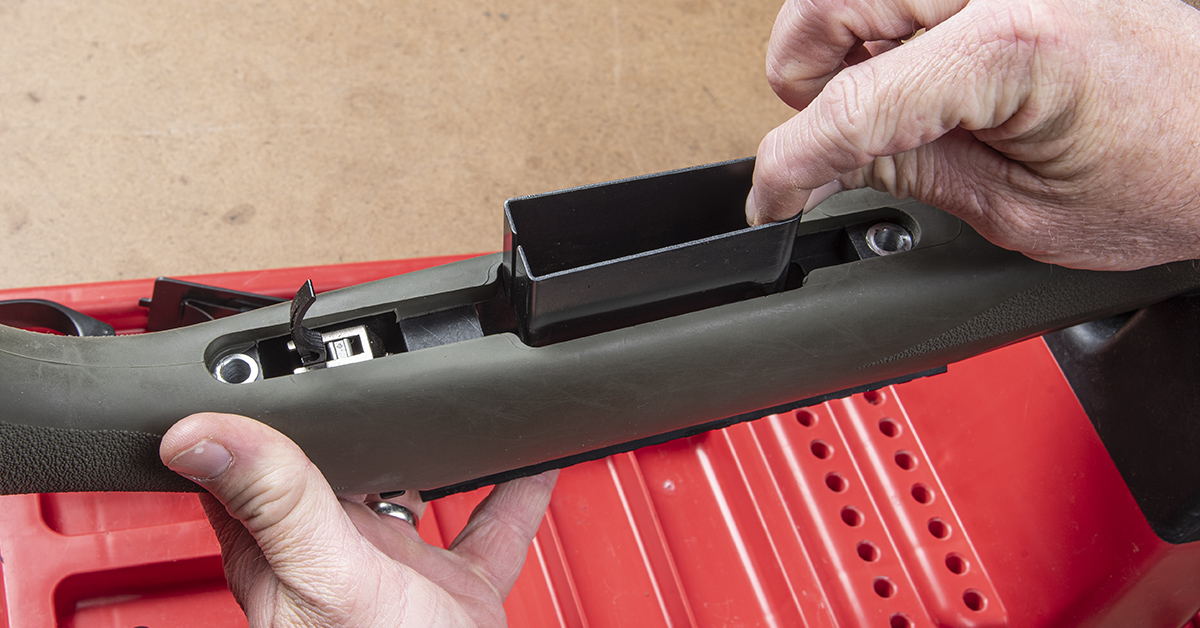

Remove the magazine box, noting the orientation.

Reset the rifle upright in the cradle and lift the barreled action out of the stock.

Carefully guide the barreled action straight down into the new stock for initial test fitment. As you go, watch and feel for any interference. The Howa barreled action dropped in effortlessly, but results may vary.

Should you find any points of contact between the stock and the barreled action, it will be necessary to remove some material within the inletting. The best tools I’ve found for this job are Jerry Fisher stock inletting scrapers.

These scrapers come in several sizes with round and octagonal scraping heads. To use, simply scrape along with the grain (or lamination) to gradually remove the high points and areas of interference.

In builds past, I’ve found the tang and trigger areas to be the most likely spots for fitment issues. Here, the round scraper heads are the perfect choice.

Regardless of the type of scraper you use to remove troublesome wood, do so slowly and methodically. The idea isn’t to create large gaps between the metal and wood, but to remove just enough wood to eliminate the interference and allow the barreled action to fit hand-in-glove in the stock inletting from the barrel lug to the tang. It is that close-tolerance fit between the barreled action and stock that, along with stock rigidity, provides the foundation for stellar accuracy potential.

Once the drop-in fitment passes inspection, secure the barreled action and bottom metal to the stock, tightening the action screws to 45 in/lbs.

Install the bolt and perform a function check to make sure that the bolt handle fully clears the stock cutout. Check to ensure the safety lever works without any obstruction, and that the trigger is similarly free to move along its full range of motion.

Moving along the stock, you can see that the inletting is quite precise on the top end, crisply following the contour of the barreled action without any hot spots.

These stocks are channeled to free-float the barrel. Running a bill between the barrel and forend revealed no interference all the way back to the action…as it should be.

Timney Trigger Upgrade

No stock upgrade is complete, in my opinion, if a trigger upgrade is not part of the equation. As mentioned earlier, the trigger is the next accuracy enhancer you need to take advantage of the more rigid stock.

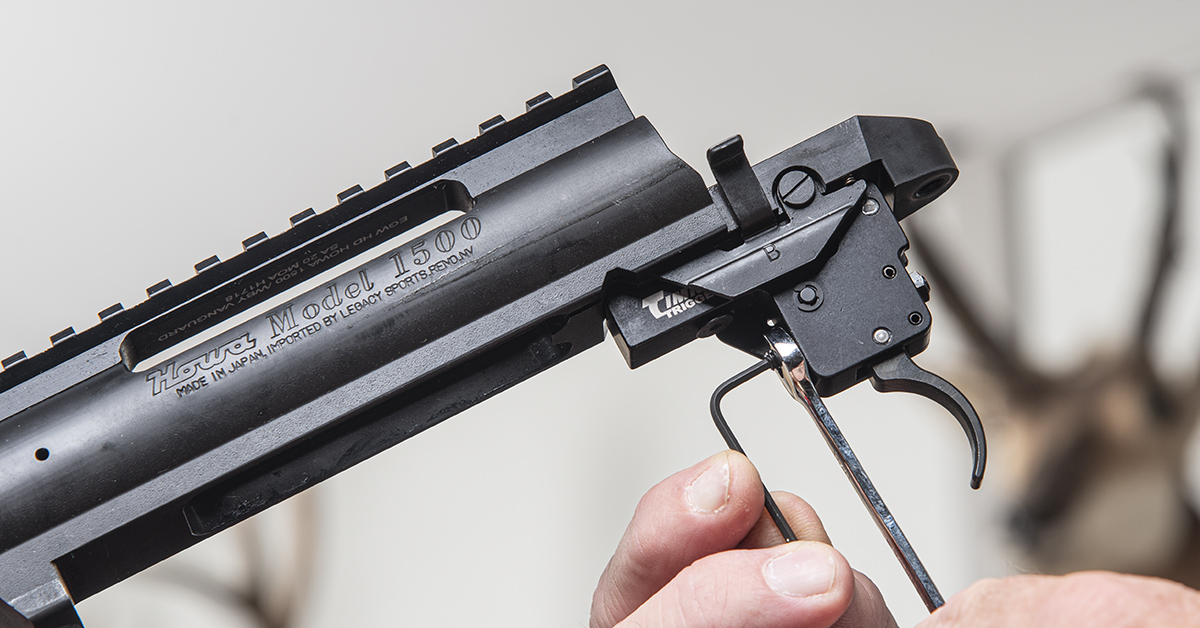

Our pick for this project was Timney’s Howa Trigger Upgrade. As with the Boyds stock, this is a simple drop in…or screw on, as the case may be. This is not to say that the Howa factory trigger isn’t top-notch. In fact, as factory triggers go, the Howa H.A.C.T. trigger found in the 1500 is an outstanding two-stage trigger with a smooth pull and ultra-crisp sear break. The switch to the Timney, though, gives the same Timney magic we’ve become accustomed to but also delivers the option of adjusting the trigger pull weight. The trigger is also of the single-stage variety, which shines in this platform.

The Howa 1500 trigger is secured to the action with a single screw. Remove it and the trigger comes right off. Installation of the new Timney trigger is simply the reverse. If your gun came with pre-H.A.C.T. trigger, you would reuse the original screw. If not, install the Timney trigger with the screw provided in the kit.

The Timney trigger comes set by the factory at around 3 lbs. Ours logged 2 lbs., 12.2 oz. Wanting just a tad lighter pull, I rotated the trigger pull adjustment screw located at the front of the housing counterclockwise until the pull average hit 2.0 lbs.

With the pull weight set, I used an Allen wrench to hold the screw in place and locked down the retaining nut with an open-end wrench.

Before installing a new trigger (especially one set for a lighter-than-average pull weight) it is important that you check it for slam-fire potential. Here, I secured the barreled action in Real Avid’s Master Gun Vise, cocked the bolt, moved the safety lever to the fire position, and aggressively hit the back of the tang with a rubber mallet. This test is to ensure the trigger isn’t set too light (unsafe condition) and that the sear engagement doesn’t break. This test was followed by keeping the safety on and, with the bolt cocked, repeatedly slamming the bolt closed in the receiver. In both tests, the sear engagement held firm, as expected.

The Scope for “Going Long”

A proper rifle makeover demands an optic that will allow the fundamental modifications (stock and trigger) to achieve their fullest potential. Since this is a hunting rifle built to tackle the long shots, the new Burris Eliminator 6 seemed the obvious choice.

This latest incarnation of the Eliminator is a somewhat radical departure from the earlier Eliminator rangefinder scopes in that it looks like a contemporary rifle optic. That’s a big plus for aesthetics and function. The ranging button and controls are located on the left side of the scope outboard of the side focus. This allows for a straight tube body (34mm) that can install with conventional mounts/rings.

Go here to see our full review of the Eliminator 6.

In its final form, this regenerated Howa 1500 cuts a striking figure, which is almost as impressive at its downrange performance. The stiffer stock adds to the accuracy potential of an already stellar barreled action just as its adjustability and the Timney trigger adds to the accuracy potential of the shooter.

But even if you aren’t looking to go full steam ahead on a rifle redo, just swapping a factory plastic stock or a well-worn wood stock for a Boyds Agility laminated hardwood model is a great way to bring an old gun to new life. It is a simple DIY process, as you have seen, and the cost is modest.

Now, while we await the arrival of hunting season, there are some large pastures in the area filled with groundhogs that require some .308 Win talking to…