Is your defensive ammo up to the task? Here are our tips for evaluating the reliability and effectiveness of off-the-shelf personal defense cartridges.

by Bob Campbell

Testing ammunition isn’t a simple thing. We all fancy ourselves savvy concerning what a handgun cartridge should do, how it should perform, and how our choice compares to other available loads. We may test ammunition to a certain extent, but we do not have the resources that some do.

The FBI has conducted extensive testing that none of us may duplicate. The Ohio State Patrol fired 228,000 rounds during a test a couple of decades ago. Federal Cartridge has fixtures to test accuracy and to take pressure readings. A writer, any writer, cannot compare his or her testing to these institutional tests. Most small ammunition companies have limited resources. Just the same, a careful and interested individual may have a high level of confidence in their personal testing if it is done properly. This is especially important in times of reduced availability and high costs. Ammunition availability is much better than the previous two years. Just the same, brand loyalty has taken a hit. Be it Black Hills, Federal, Hornady, Remington, Speer, or Winchester. You are probably going to compromise on ammunition selection and obtain what you can purchase.

There are ammunition test programs that have been carefully conducted. The FBI chose Hornady’s 9mm 135-grain Flex Lock to meet their needs, as an example. The balance of penetration and expansion leans toward penetration. What if you cannot find this load? Is your next choice comparable? The Federal HST is a great load, but how does it compare to a local reloader’s load? Winchester Silvertip or Black Hills EXP? Will one do pretty much what the other will?

While shot placement is most important, there are certain parameters we find essential and which we should confirm, and that requires a certain amount of equipment. The first tool is a chronograph. You must be able to test velocity. The major ammo manufacturers are usually spot on with published velocity, with normal variations for barrel length. Powder doesn’t fully burn in a shorter barrel. The longer the barrel the more complete the powder burn. A full powder burn results in a more modest muzzle signature.

Occasionally, a manufacturer will grossly inflate velocity. I tested an 85-grain JHP in .380 ACP rated at an astonishing 1280 fp. I knew this wasn’t possible in this caliber. Sure enough, the Ruger LCPII clocked 990 fps. Another company was 200 fps short on their 9mm and .38 Special loads.

The chronograph need not break the bank and I don’t need print outs or a lot of memory. I look for an accurate unit such as my Competition Electronics ProChrono. I have an RCBS for back up and have also used an inexpensive Caldwell chronograph. When I have a result I question, I sometimes use the backup chronograph to confirm my results.

It is also good to have an exemplar load to confirm your results. As an example, I have an old Heritage .22 revolver and a box of Winchester Wildcat I use to test the chronograph, making sure the readings are the same from one session to the next — accounting, of course, for a slight environmental deviations.

I also keep on hand a shooting rest. There are several that work well but the rest I most commonly use is the MTM Case-Gard K-Zone rest. The K-Zone rest is affordable and may be used for rifles or handguns.

As for velocity there is a certain plus and minus deviation allowed in certain lots of ammunition. A certain lot of 115-grain 9mm may, for instance, reach 1180 fps and the next load 1214 fps (actual results with Winchester Silvertip). Either will perform well. The ballistic scientist’s job is to maintain precision with each lot of powder while maintaining a certain pressure level.

When testing non-critical ammunition, including handloads, I skip some procedures. I may not need to test terminal ballistics with a hard-cast SWC intended for hunting boar, for example.

Before testing defense loads, I conduct several non-firing tests. Observing the primer under magnification for proper seating is important. I also test cartridge integrity using three containers. A plastic container or lid from an aerosol can works fine. I place a single cartridge in a container filled with water, oil, and solvent, respectively. I let the cartridges soak overnight and then take them to the range. If they do not fire, then the loading isn’t suitable for personal defense. After all, we sometimes carry our firearms in damp conditions and the pistol may have oil and solvent in the action.

If the cartridge fails to fire, it is seldom the primer. It is usually the powder that has failed.

Be careful, as the primer may propel the bullet slightly into the barrel (although a crimp may prevent this). Be prepared with a bullet rammer.

Primer seal is vital, in my opinion. The blue splash on a Federal primer is primer seal. It is red on Winchester primers.

It isn’t well-known that some loads also use case mouth sealer. A tight fit in the primer and projectile are usually sufficient. Additional sealant is better. (Nail polish works well with handloads.) The more pedestrian loads such as American Eagle, Remington UMC, and CCI Blazer may not use case sealer, and that is fine. They are not designed for duty.

Next — and this is best accomplished in the safety of a firing range — is checking for setback. This involves holding open the slide, inserting a single cartridge into a magazine, seating the magazine into the mag well, and depressing the slide release lever, allowing the slide to push the cartridge out of the magazine and into the chamber. When doing this, the bullet must not set back into the cartridge case.

I repeat the procedure by running the cartridge through the action five or six times. The cartridge should not push back into the case. I can guarantee that if setback does occur, the cartridge integrity has been compromised such that oil, water, or solvent could enter the cartridge case.

Pressure is driven up as well. I once tested a foreign-made cartridge that jammed into the chamber on loading and could not be extracted by pulling back on the slide. It had to be fired out! The whole box was the same.

Most loads pass the previous tests. If not, they are unsuitable for duty use.

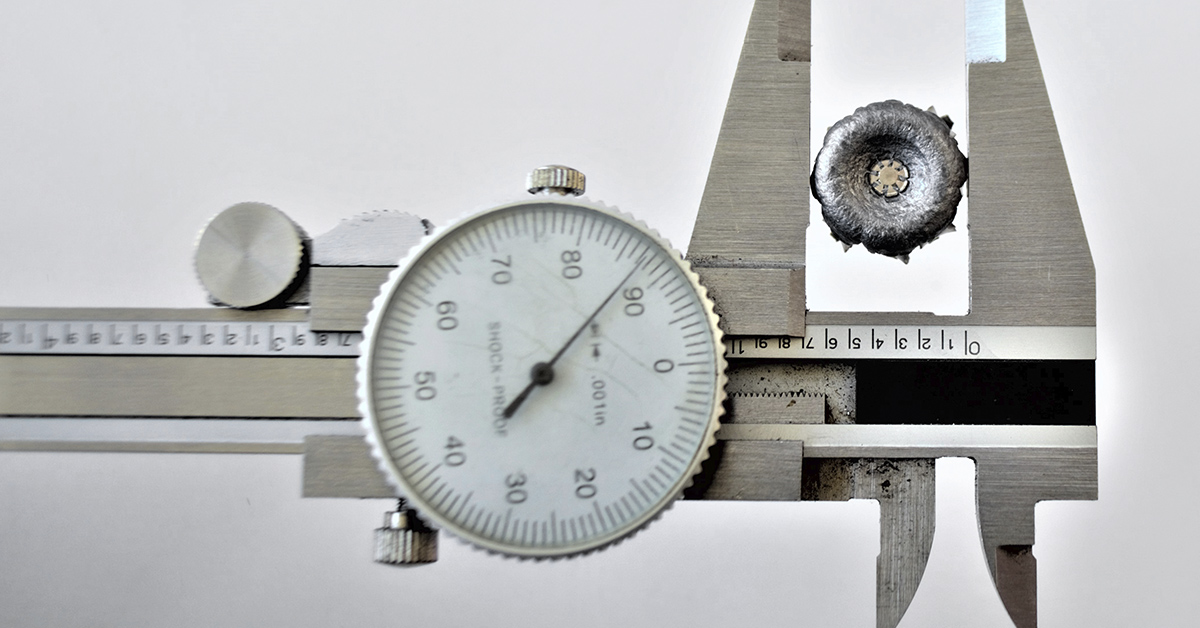

A dial or digital caliper is essential for this test. To judge setback, you must first measure the cartridge overall length. As an example, for best feed reliability, a .45 ACP cartridge overall length should be 1.250 inches. Shorter than that and you may have difficulty in feeding.

The next test is firing for velocity. I use a bench rest, and also fire for accuracy. Accuracy is relative. Just the same, a personal defense load should be as accurate as a FMJ practice load.

Some companies make outrageous velocity claims, and this must be dealt with. I recently tested a 9mm Luger with a 124-grain JHP. While 1100 fps is common, most loads in this bullet weight run 1180 fps, as does the Federal HST. This load, though, averaged 999 fps in the Beretta 92. Bottom line: it was “underloaded.” Testing this load for expansion was unnecessary since I wouldn’t use it, but I did so just the same. The bullet penetrated 34 inches of water and failed to expand. While too much pressure and velocity may be counterproductive, a certain minimum range of velocity is required for expected terminal performance.

If a cartridge is reliable, features good primer and case mouth seal, provides reasonably accuracy, has limited muzzle flash, and offers acceptable velocity, the load is proofed for defense use…to a point.

Next, we test expansion and penetration. The FBI uses a special formulation of gelatin for this. The primary advantage of gelatin is that after the bullet penetrates gelatin, a cast may be made of the wound cavity, saved, and compared to other loads. Clay, mud and duct sealant are not realistic test mediums as these materials don’t “give” enough and will cause even poorly designed bullets to expand. I am not familiar with the exact type, but Europeans once used a form of adhesive to test ammunition.

I use water for many reasons. Water, as far as penetration and expansion, is within ten percent of gelatin results. Gelatin is viable and may approximate animal tissue, but when you throw in hard bone and muscle, it isn’t that close. Still, gelatin is good and an excellent test medium, although it is difficult to mix well and to keep consistent. Water, though, is consistent, is easy to use, and therefore is a good source for comparing loads.

I use six-inch wide water jugs. As a rule, we expect a bullet to expand to 1.5 times the original diameter. With a full size 9mm or .45 ACP pistol, this is a reasonable goal. Snub-nose .38s and 3-inch barrel 9mm handguns may not meet this goal. I like to see 18 to 20 inches of penetration in water. If the bullet expands enough to create a plump mushroom or at least a blunt nose, that is good. Minor calibers such as the .380 ACP have a much more difficult time managing a balance of expansion and penetration. Of the two, penetration is the most important.

I often test ammunition for a couple of criteria and do not do the full test. As an example, there is no need to test .45 ACP 230-grain hardball for wound ballistics as this load has been tested often. There are many loads, though, that will never be tested by big agencies, so gelatin data are not obtainable. For instance, I recently tested some of the first .30 Super Carry loads with excellent results.

Caution. Some find fiction more interesting than technical research. Science doesn’t ask you to believe but presents results that are repeatable and verifiable. There are velocity and bullet performance claims that do not pan out in testing. There are so called “stopping power studies” that are suspect at best — if the data was collected as claimed. Wound potential is a science. Facts are presented. Secret sources? One group convinced an unsophisticated minority that a test had been undertaken in which goats were shot and the time for the goat to die was measured. While the secret society that supposedly undertook this test is unknown, I cannot see what the value would have been, and it certainly isn’t the type of test that military or police institutions would conduct. Beware of such skullduggery. A pundit telling you a bullet “expands viciously in flesh” most often has nothing more to go on than ad hype.

Do your own research. Study the tests by those with proper equipment and motivation beyond the commercial to choose a load well suited to personal defense and duty use. Take your own counsel and conduct your own tests. The results are rewarding.